Advanced Robotics for Manufacturing (ARM) Announces Selection of Four New Technology Projects

ARM’s active project count has increased to 49 with this new selection.

December 2, 2019 – ARM (Advanced Robotics for Manufacturing) is pleased to announce four new selected projects from its fifth Technology Project Call that took place earlier in 2019. This increases ARM’s selected projects to 49, and now involves 44% of its 220 member organizations. Pending final negotiations, ARM plans to provide more than $1.6 million in funding for a total investment of approximately $5.3 million across the four projects.

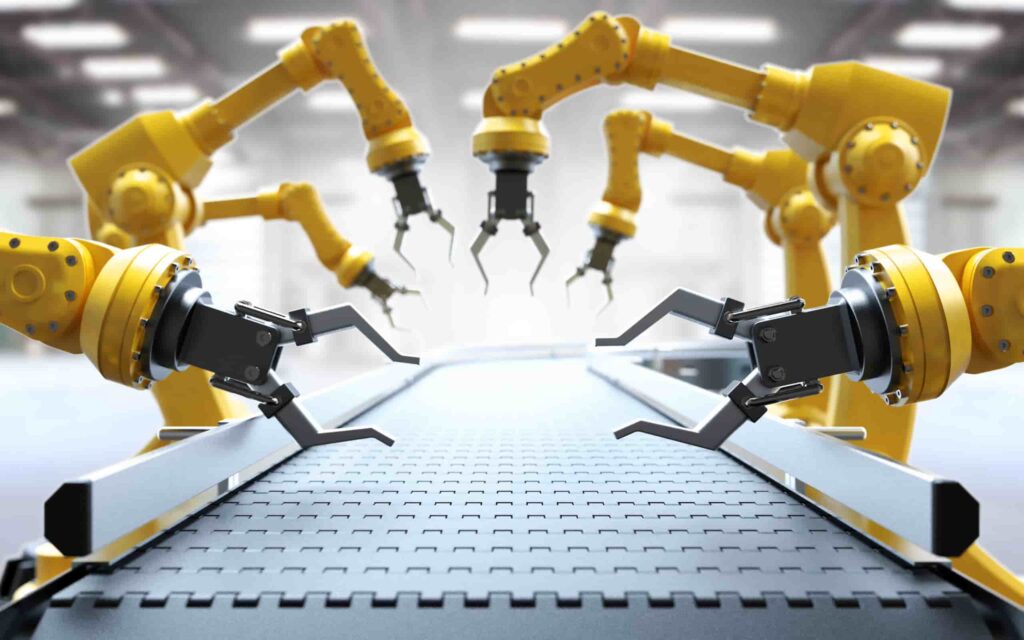

Manufacturing is key to securing America’s future, and with the fourth industrial revolution upon us, US companies are pressured to quickly adopt automation and robotics to remain competitive. ARM seeks to ease this burden by identifying the most critical technology and workforce problems and issuing project calls to its base of 200+ member organizations to catalyze solutions for American manufacturers. These projects will strengthen US manufacturing and are in line with the technology investment plan approved by members

“These projects epitomize the strength of the ARM consortium, bringing together diverse organizations to improve manufacturing processes and lower the barriers to adopting robotics,” noted ARM CTO Arnold Kravitz, “These projects help to ease issues inhibiting growth in US manufacturing, while elevating the human roles.”

Human-Robot Collaboration in Quality Inspection

Principal Investigator: Fiat Chrysler

This project seeks to improve the processes surrounding part quality inspection through the development of an easily programmable robotics 3D inspection system. Success will be measured through improvements in resolution, cycle time, programming time, and enhanced insights. By project end, the team intends to demonstrate an automatically calibratable system that will work with existing CMMs.

Path Planning for Precision Brazing

Principal Investigator: Siemens

Current precision brazing operations rely on highly manual processes in hazardous environments with high temperatures and noxious fumes. As such, there are a limited number of skilled welders to perform these processes. This project seeks a collaborative robotic solution to supplement the workforce gap through a system where the robot ensures precise flame and temperature control while a skilled operator performs quality control and adds filler material.

SAFE: Safe Autonomy Features in the Edge

Principal Investigator: Siemens

This project seeks to leverage advancements in sensors, edge intelligence, robotics, and fail-safe controls to ensure the safety of human workers around their robotic counterparts, specifically AGVs. Current AGVs are limited to moving on a pre-defined path in a highly controlled manner, limiting real-time decision-making opportunities for human counterparts. This project team aims to improve human sensing and perception in AGVs, allowing for wider and safer applications.

Systematic Robotics Application Assessment Methods and Tools for Decision-making

Principal Investigator: Schlumberger Technology Corporation

Due to the cost and perceived risk with implementing robotics, advocates are often putting their reputations on the line when advocating for adopting robotics in manufacturing processes. This project seeks to minimize risk to manufacturers by improving upon methods and tools for evaluating manufacturing readiness levels for robotic applications. The expected project outputs include an expert-system-based software platform that identifies the key robotics parameters for a given manufacturing process and suggest solutions.

New Project Calls

ARM currently has an active Education & Workforce Development Project call. Proposals for this call are due on Wednesday, December 11, 2019. Note that you must be an ARM Member to submit a proposal.

Additionally, earlier in November, we announced that ARM has been chosen to facilitate and manage a NEW technology project call for the Department of Defense, focused on Sustainment. The call and supporting documents will be available for download on our Member Community and public website on December 4.

Learn more about our active project calls here.

ABOUT ARM

Advanced Robotics for Manufacturing (ARM) is the nation’s leading collaborative in robotics and workforce innovation. Structured as a public-private partnership, we accelerate transformative robotic technologies and education to increase U.S. global manufacturing competitiveness. Founded in January 2017 in Pittsburgh, PA by Carnegie Mellon University through an independent non-profit, and funded by the Department of Defense, ARM is part of the Manufacturing USA® network. Learn more at www.arminstitute.org.