Project Team

Siemens Technology (PI), Sewbo, Henderson Sewing, Industrial Sewing and Innovation Center (ISAIC), and Bluewater Defense

Background

The apparel manufacturing sector is ripe for automation, but robots have difficulty manipulating and handling pliable materials, which has inhibited the integration of automation in the industry. Because of this, most sewing is still completed manually and a majority of apparel manufacturing is located outside of the U.S. in countries where labor is less expensive. In fact, less than 3% of the clothing that Americans wear is manufactured in the U.S. (source).

The apparel manufacturing sector is ripe for automation, but robots have difficulty manipulating and handling pliable materials, which has inhibited the integration of automation in the industry. Because of this, most sewing is still completed manually and a majority of apparel manufacturing is located outside of the U.S. in countries where labor is less expensive. In fact, less than 3% of the clothing that Americans wear is manufactured in the U.S. (source).

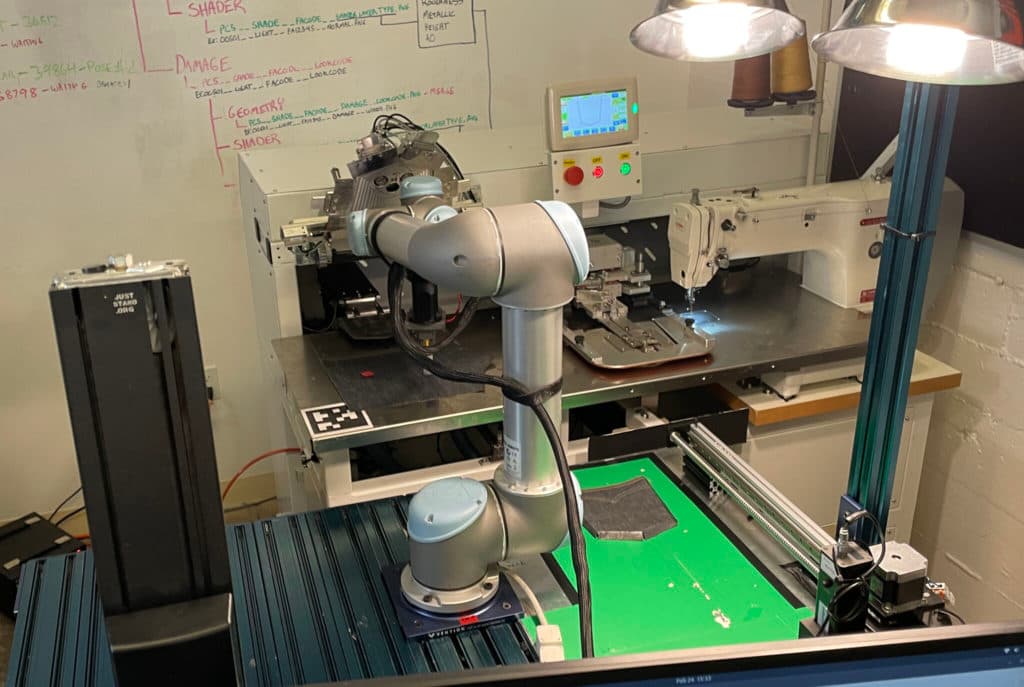

Since 2018, the ARM Institute has completed six projects that have significantly advanced the state of the art in robotic sewing. The teams’ early work integrated sewing machines with collaborative robot systems and designed an end effector capable of lifting and controlling a single large ply of fabric. Recent projects have built upon these developments to be able to robotically conduct more advanced operations like hemming, fabric fusing, pocket setting, and curved stitches. On February 24 2022, the Bot Couture project team demonstrated the latest robotic sewing technology in the construction of denim pants at the Levi Strauss Innovation Center in San Francisco, CA.

These developments have the potential to begin re-shoring apparel manufacturing.

Approach

By building on the advancements and outputs of previously funded ARM Institute projects, the Bot Couture project advanced the state of the art in robotic sewing and demonstrated the feasibility of the technology in a representative environment at the Levi Strauss Innovation Center. Through the project, the team developed a robotic system which can be used to perform machine tending operation in the apparel sector and a closed loop visual servoing technique to perform precise sewing. The team also developed modular software components that can be reused in this and other industrial robotics applications.

Impact for the DoD

The Department of Defense (DoD) buys an extraordinary amount of sewn goods – from uniforms, to tents, to parachutes, and more. By using robotic systems to produce these inexpensively in the US, we will secure our supply chain and reduce costs. Commercial companies like Levi’s, DoD suppliers like Bluewater Defense, and sewing machine technology providers like Henderson Sewing Machine Company are seeking to integrate this capability into their processes and products. These ARM Institute projects are directly complimentary to the work undertaken by AFFOA and Drexel’s Center for Functional Fabrics.

The ARM Institute’s Role

“Thanks to the ARM Institute, we can come together and provide viable solutions to problems all manufacturers have, not just us at Bluewater. This project is the beginning of an automation journey that is much needed in the garment manufacturing industry, a sector of the economy that has not seen a lot of innovation in the past. The ARM Institute helped us connect with other members like Henderson Sewing Machine Company, Sewbo, Siemens, and Levi’s to come together and pursue this common goal.” – Auralis Herrero-Lugo, Commercial Product Manager at Bluewater Defense

About the ARM Institute

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse ecosystem of 300+ consortium members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and Twitter.