This month’s five questions interview features ARM Member Curtis Richardson from Spirit AeroSystems! Curtis has been an ARM Institute Member since the Institute’s inception in 2017 and has participated on the Stakeholder Executive Committee (SEC), which serves as the voice of the ARM Institute’s nearly 400 member organizations, for many years. In his role on the SEC, Curtis provides input on the ARM Institute’s strategic direction to the ARM Institute’s leadership team.

1. We like to start our interviews by exploring how our members got started in manufacturing. Can you tell us more about your background and how you became interested in manufacturing? Can you tell us about your role at Spirit AeroSystems?

The summer after my junior year of college, I was fortunate to get an internship with Boeing. As an aerospace engineering student, I expected to be doing design or stress analysis work, but instead I found myself in something called Manufacturing Research & Development (MR&D). My grandfather had worked in factory logistics at Boeing for nearly 40 years following WWII, so I knew there was more than just traditional product-focused engineering there, but I never thought it would be something that would interest me. Boy, was I wrong!

Being exposed to all the intricacies and challenges of the manufacturing process for complex aerostructures was an incredible education. Some truly terrific mentors taught me the ins-and-outs of aircraft manufacturing in general and also introduced me all interesting technologies like composite materials, metrology systems, precision drilling and fastening, assembly techniques and something called “rapid prototyping” (today we call it 3D printing or additive manufacturing).

My interest in robotics was initially sparked by randomly walking by and stopping to watch a Tricept NEOS (one of the first parallel kinematic industrial robots) cell in the factory. I recognized the benefits of this type of flexible automation and knew that’s where my future would be. My mentors and management let me run with my enthusiasm, and I eventually became the site leader for robotics. Shortly after our division separated from Boeing to form a new independent company (Spirit AeroSystems), I was accepted into the Technical Fellowship program and became Spirit’s global leader for robotics and automation. That role is an enterprise leadership position that incorporates technical expertise and business acumen into a strategic corporate function. While being a consultant for internal technology development and investment efforts, an important part of my job is also to lead engagement with outside partners and entities like the ARM Institute.

2. Each time the ARM Institute visits Wichita, we are impressed by the relationship Spirit has with Wichita State University and WSU Tech, both of which are ARM Endorsed training programs for robotics careers in manufacturing. Can you tell us about Spirit’s relationship with WSU and how this collaboration helps to fill Spirit’s talent pipeline?

Spirit and WSU and WSU Tech have built a strong partnership on many fronts, and our work together in the area of robotics is probably one of the best examples. WSU Tech established its Robotics program around 2009 based in part on input and support from Spirit and other area manufacturers. Likewise, Spirit’s input to WSU’s College of Engineering helped shape the origins of the Engineering Technology degree program around 2011, especially the Mechatronics track. It was envisioned as a pathway from WSU Tech’s Robotics Associate degree to a Bachelor’s program, providing educational and career growth opportunities.

Beyond those initial contributions, Spirit provides on-going support by participating on their Industrial Advisory Teams, as well as several others like that of the Industrial Systems and Manufacturing Engineering department. It’s a valuable communication mechanism that lets us provide an industry perspective on curriculum and observations of student skills from involvement in senior projects and our internship program. We can also collaborate with faculty and administrators on new curriculum and technologies to address emerging industry needs.

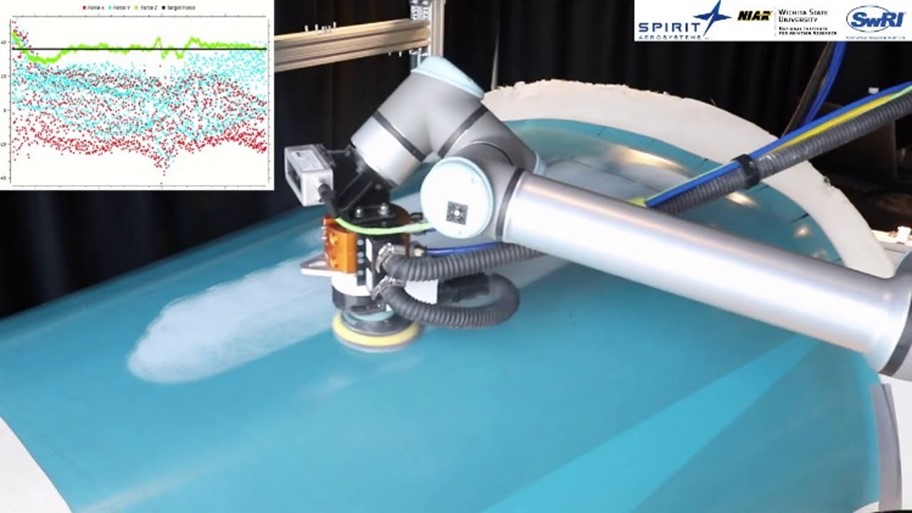

Spirit also opened an engineering office and R&D lab on WSU’s main campus. We use it as a collaborative space to embed students with teams conducting advanced product, software, and technology development. This earn-and-learn approach allows us to introduce students to real-life complex engineering at the same time they’re learning relevant subject matter and skills in their classrooms just a couple of buildings away. This location also gives us very convenient access to WSU’s National Institute for Aviation Research (NIAR) labs and personnel that we rely on as a partner in many of our development efforts.

3. You’re a member of the ARM Institute’s Stakeholder Executive Committee (SEC), which acts as the voice of the ARM membership. Can you tell us about your experience on this Committee?

It’s been a privilege to be a member of the SEC since it was kicked off in 2018. The composition of the group has been diverse with membership including end users, solution/technology providers, researchers, and educators that represent industry, academia, government, and even other consortia and associations. It makes for a good overall representation of the broad spectrum of the ARM Institute’s membership. The discussions during our meetings have reflected that in terms of unique perspectives and at times even passionate debate. From my standpoint, the SEC members have done an admirable job of bringing the varied priorities and interests of members they represent to the conversation and driving consensus in support of win/win situations.

As I said in my original SEC candidate statement, one of the most crucial aspects of the ARM Institute is fostering a robust ecosystem that ties together all stakeholders with effective communication. The SEC has worked closely with the ARM Institute’s leadership and staff to identify opportunities to do this and results can be seen in things like the online member portal, webinars, newsletters, surveys, focus groups, and the many aspects of the Annual Member Meetings. To be clear, the SEC collaborates with the ARM Institute team to identify and concept these opportunities, and then ARM staff then does an incredible job of turning them into reality!

One of the most interesting aspects of my experience on the SEC has been in contributing to, reviewing and providing feedback on the institute’s technology investment strategy and associated roadmaps as well as the project call process. Having such a diverse group of people weigh in on these topics has really helped me understand challenges across the member ecosystem, in addition to recognizing areas of commonality and ways we can cooperatively address our needs.

4. Speaking of the SEC, the SEC members are helping the ARM Institute launch new Technical Working Groups. Can you tell us a little bit more about that effort and the SEC’s involvement?

The ARM Institute’s new Technical Working Groups were conceived to address two basic needs. First, they have a very practical purpose in providing a rallying point for members with common issues and technology interests. It’s a way for members to identify others in the ecosystem who may be facing similar challenges or who may have solutions to challenges within broad domain topics like Autonomous Mobile Robots (AMR) or Human Robot Interaction (HRI). They can also then leverage these new relationships as another way to identify potential teammates for future project calls.

Second, the working groups are intended to simply help ARM Members get engaged. The SEC has heard from members that if you’re not actively participating in a funded project or not part of a group like the SEC or Technical Advisory Committee (TAC), you can feel distanced from the institute and find it difficult to connect with other members, especially if you’re not located near the ARM Institute’s headquarters in the Pittsburgh area. The working groups will be another way to create those connections and build those valuable networks. And they will be open to every member of the institute, from start-ups to large corporations and universities and government reps.

[ARM Institute note: Members can expect to learn more about our Working Groups at our Annual Member Meeting taking place Nov. 13-15 in Pittsburgh, PA.]5. We’d be remiss if we didn’t mention the many ARM Institute projects that Spirit AeroSystems has participated in over the years. Can you tell us about your experience participating in ARM Institute projects?

Different from many industry members, Spirit has a dedicated internal applied R&D organization that develops technology and deploys factory solutions. So we have played both the project leader and supporting team member roles on ARM Institute-funded projects. The experiences have been positive ones, working with great teammates and building relationships with the ARM Institute’s project management staff. And we are transitioning our developments into production scenarios, which is the real end-game.

To be transparent though, at times we struggle to identify topics for project proposals that we feel comfortable exposing to other members for intellectual property (IP) reasons. We’re learning and getting better at it, but I know that’s something that can hold members back from participating.

We’ve also participated in a few ARM Institute initiatives like the AI Discovery Workshop and the RoboticsCareer.org focus group related to the new job finding/matching functionality recently rolled out. In each case, the staff we worked with were focused and efficient and conveyed genuine gratitude and interest in the feedback we provided. And we could see the evidence of our input in the final results of each effort, which is the real litmus test.

6. Bonus Question: Registration is now open for the ARM Institute’s Annual Member Meeting taking place November 13-15 in Pittsburgh, PA. Can you tell us what value you’ve found in attending the Member Meeting in years past?

Attending (and participating!) in the Annual Member Meetings can be a game-changer in terms of your engagement with the ARM Institute. It is absolutely the best way to experience the institute’s diversity and to network with new members, including potentially meeting someone who might become essential to your business by way of developing a solution to your problem or becoming a customer for you. That’s something very difficult to do successfully in even the best virtual meeting environments. And I expect this value in attending will increase as the working groups are established and really take off.

The Annual Meeting is also a great opportunity to learn what’s happening at the ARM Institute itself and how the institute is interacting with and responding to government sponsors and other funding providers. The slate of speakers is always top-notch and offer good insights into government needs and priorities in addition to industrial and academic capabilities and developments.

[ARM Institute note: The Annual ARM Member Meeting is free to attend, but open only to ARM Institute Members. ARM Members can register in the Member Community. Email [email protected] with any questions or to learn how to become a member.]Don’t miss another update!

Join our mailing list

ABOUT THE ARM INSTITUTE

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse ecosystem of nearly 400 consortium members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017 with a regional office in St. Petersburg, FL, the ARM Institute is leading the way to a future where people and robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and Twitter.