ARM Institute Members are varied in their focus areas, sizes, and history, but one common thread unites each organization: a drive to build the future of US manufacturing. Each of member organization leverages their strengths and areas of expertise to secure a brighter future for the US workforce, a stronger Organic Industrial Base (OIB), and a more resilient manufacturing economy.

For this month’s five questions piece, we chatted with Kevin Beamish, Chief Operating Officer at ARM Member BG Workforce, a Steel Level ARM Member! BG Workforce Solutions equips the U.S. Military, Federal Government, Allied Military, and Domestic Organic Industrial Bases with the solutions and tools necessary to recruit, train, and sustain a skilled workforce.

Get to know Kevin’s background, how ARM Members can collaborate with BG Workforce, the ways BG Workforce strengthens the Organic Industrial Base, and how the organization formed new connections through the ARM Institute’s 2025 Annual Member Meeting in the interview below!

1. We always like to start by exploring our expert’s background! Can you tell us about your professional background and your role at BG Workforce?

I’m responsible for day-to-day oversight of company operations, strategic planning, and business development. I’m also the primary person responsible for user training and customer support for our suite of software products. I joined BG Workforce in 2022 as the Director of Training just as BGW was making its first foray into supporting the Defense Industrial Base. I’m formally trained as an engineer with a B.S. in Aerospace Engineering from the University of Tennessee, Knoxville whereas an undergraduate research assistant I designed and test fired 3D-printed rocket motors as part of a NASA-Marshall Spaceflight Center research project.

I started my professional career working as a civilian engineer supporting naval aviation maintenance at the Fleet Readiness Center in Jacksonville, FL, where I quickly learned that engineering school had taught me nothing about how to fix airplanes and helicopters. I spent the majority of my time the next several years on the hangar floor learning aviation maintenance from the experienced technicians and artisans who did that work day-in and day-out, and realized that if the engineers disappeared the planes would still fly, but if the artisans disappeared there would be no more flying! I gained tremendous respect for the work that those folks do.

Eventually I went back to school to earn a M.S in Space Systems from the Florida Institute of Technology, while at the same time earning an A.S. in Engineering Technology (Advanced Manufacturing) from Florida State College at Jacksonville. While studying for those degrees I was working night shift in private industry at an advanced manufacturing facility, operating advanced robotic systems and complex CNC equipment. I had plans to go to work in the spaceflight industry, but sort of stumbled into a career in technical education when Florida State College asked me to return to the school as an instructor in their advanced manufacturing program I had recently graduated. There I taught classes in multiple industrial trades, including robotics and industrial automation. I also developed & taught multiple professional apprenticeship and professional training programs for several local Fortune 100 companies. It was in this position I met the team who founded BG Workforce, who asked me to join the company because of my background in the Defense Industrial Base and in workforce training & development. Since then, I haven’t looked back and have loved every minute of my time with BGW!

2. Let’s dive a little deeper into BG Workforce. What would you like other Members to know about how they can collaborate with your organization?

BG Workforce is built for partnering! Our mission is to help other companies in the wider defense industry unlock the potential of their skilled technical workforce using our technologies. We provide secure Department of Defense (DoD)-cloud approved software that focuses on quickly and effectively developing technical workforces and manufacturing operations, and partners can utilize our digital infrastructure to develop & deliver their knowledge content. We partner with private businesses and public institutions to develop and implement modern skilled training programs to feed workers into the Defense Industrial Base. We can develop specialized training and knowledge support content, as well as provided subject matter expert workers to fill critical needs in manufacturing operations. When it comes to skilled workforce development, we specialize in all aspects of it! We are always happy to speak with anyone working in the cloud-based software, manufacturing and industrial maintenance, and training/workforce sectors. Just reach out to me to schedule an introduction!

3. BG Workforce works extensively with the US military on workforce readiness. From your experience, can you tell us why workforce readiness is so important for the Organic Industrial Base (OIB) and Defense Industrial Base (DIB) and how your work is strengthening the OIB & DIB?

That’s a great question. We were brought into DoD contracting to address what the Pentagon has (rightly) identified as a major national security threat: the diminishing technical workforce in the defense industrial base.

In general numbers, there is a projected need for over 200,000 workers in the next decade to support the Submarine Industrial Base, with the wider domestic manufacturing industry as a whole expecting a shortage upward of 3.5 million skilled workers in that same time. When compared to near-peer adversaries, the state of our national skilled workforce presents an extreme risk to continued American military and economic superiority.

The current industrial base workforce is also rapidly aging, and when those workers retire they take their decades of knowledge and skill with them as they go. While capital technology has rapidly modernized in the manufacturing industry in recent years, the knowledge-support technology which enables skilled workers has significantly lagged. Our mission has been to leverage our technology to capture that legacy knowledge, codify it, and distribute it in an intelligent and targeted manner to significantly accelerate speed to competency for new and developing workers. Our systems enable the real-time mapping of workforce skills, competencies, and overall readiness. We also design, build, and manage technical skills training programs and physical schoolhouses to develop the next generation of workers from scratch. Our newest business foray is into the development and operation of advanced manufacturing production facilities, completing the pipeline of technical worker development to employment. Around that pipeline we leverage emerging technologies in Artificial Intelligence (AI) and Extended Reality (XR) – like what we are working on with the ARM Institute – to vastly enhance the quality of the user training experience in all types of environments.

4. We were excited to see BG Workforce team at our 2025 Annual Member Meeting! Can you tell us about your experience at the event and the value you found in it?

The ARM Member Meeting was the highlight of our conference season! We go to A LOT of conferences and were excited for the opportunity to attend and exhibit at this year’s ARM Institute event as brand new members. We had the opportunity to deliver a 5-minute pitch to the conference, sit on a discussion panel, and demo our technology to visitors at our booth. Our team was extremely impressed by both the quality and quantity of great connections we were able to make with other attendees and also found the programs and speaking events highly informative and entertaining. The ARM Institute outreach team deserves a big congratulations for a job well done, and we’re looking forward to attending again next year!

[ARM Institute note: Our Member Meeting is our annual, member-exclusive event. Our 2026 event will take place Nov. 17-19 in Pittsburgh, PA. Join our consortium to be eligible to attend. ARM Members can access presentations from our 2025 event, including BG Workforce’s five-minute pitch and panel discussion on the ARM Member Community.]

5. We learned that you made a connection to ARM Member Festo while at our Annual Member Meeting, can you tell us more about how the Member Meeting helped to facilitate that connection and the resulting impact?

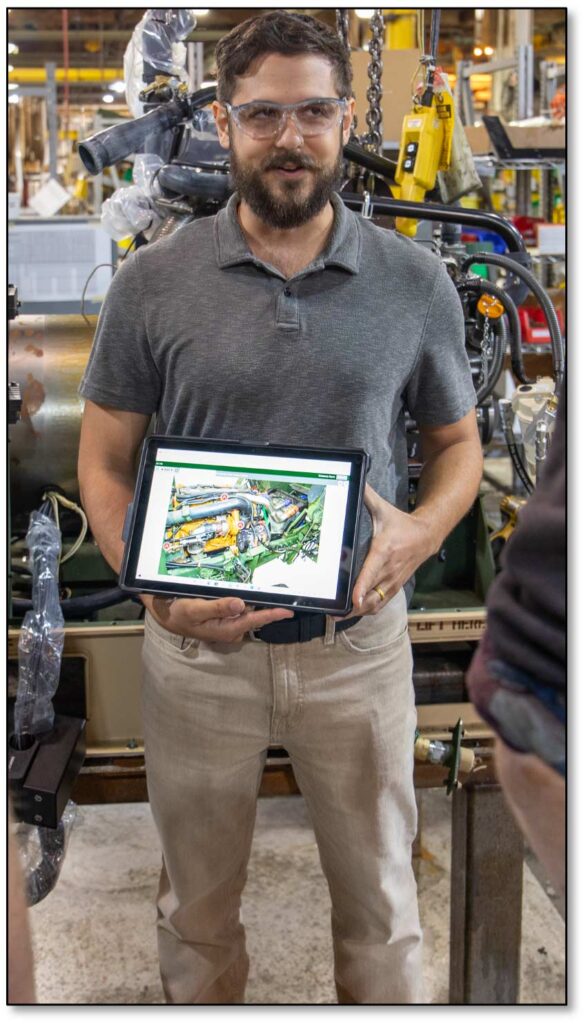

We did get to make a connection with Festo at the Member Meeting! We’ve used Festo products in the past on other projects, but the time we spent together at the conference opened up some new doors for deeper collaboration! Our current ARM Institute project, focused on innovative AI & XR technologies for workforce training, is now using Festo equipment & curriculum as the training asset. So, if you see us at another conference, you’ll be able to demo our technology as it teaches you how to configure and operate Festo manufacturing training systems!

On the other hand, we’re helping Festo leverage our DoD training infrastructure to deliver their high-quality training content & equipment into the DoD organizations that badly need it. This emerging enhanced partnership was all spawned because we sat on a discussion panel with Festo, got to talking with old connections, went together to a Pirates baseball game (they won!), and had the opportunity to deep dive into each other’s business needs. We’re extremely grateful for having had that opportunity.

[ARM Institute note: If you are a Pirates fan, you understand that it’s notable that the Pirates won the game these two members attended. Our organization takes credit and believes that the spirit of collaboration that BG Workforce and Festo brought to the event enabled the Pirates to come together and (finally) win.]

Join BG Workforce & Our 450+ Member Organization in Building the Future of US Manufacturing

ARM Institute Members lead the way to a future where people and robots work together to respond to our nation’s greatest challenges and to develop and produce the world’s most desired products. By becoming a member of our 450+ member organization consortium, you’ll join thousands of subject matter experts in building the future of US manufacturing through robotics, AI, and workforce innovations. Your membership to our robotics institute unlocks not only access to member-exclusive events and webinars, including our Annual Member Meeting, but also project funding opportunities, project outputs, networking, a digital platform for collaboration, and more.

ABOUT THE ARM INSTITUTE

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique and robust consortium of 450+ members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and X (formerly Twitter).