In this month’s “Five Questions” piece, we interview ARM’s Chief Technology Officer, Arnie Kravitz, about one of the industries that is ripe for automated solutions – apparel production.

1. When looking at the use of robotics across industries, it is hard to find significant use of robots in apparel, textile, and composite production. Why is that?

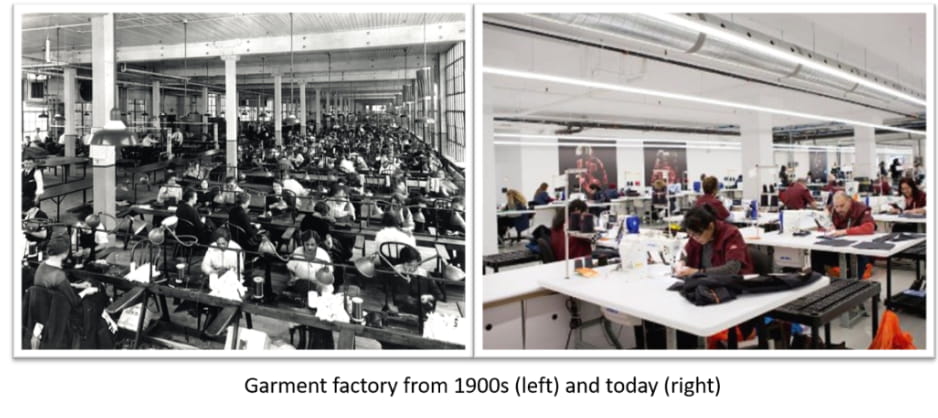

There is significant opportunity for robotics automation in apparel manufacturing. The industry itself is very efficient, but due to the nature of the product, sewing is still done manually. In fact, very little has changed in sewing, as show in this picture of one factory from the early 1900s and one from today.

The challenge really comes in with the manipulation and handling of pliable materials, like fabrics, to produce a garment. Modeling how fabric will drape, stretch, and form when manipulated is difficult, but ARM is funding several projects that do just this. More on that in a later question.

2. What has changed to make the use of robots in this industry attractive now?

A change in the market preferences toward custom service and rapid distribution is creating an opportunity for robotics to supply the low volume, high mix marketplace – think of customizing your shoes or a T-Shirt. Simultaneously, a new generation of entrepreneurs supported by the existing apparel industry and other large engineering companies are applying, AI, visual systems, advanced path planning, and other innovations, like the stiffening of fabric to make handling easier.

3. Where can robots make the biggest impact today in the apparel industry?

As mentioned previously, robots can make a big impact in the service-oriented, custom product portion of the apparel industry. It can also make an impact in supplementing the existing workforce in the United States. Today the USA only manufactures about 4% of the apparel we wear. Bringing robots into existing U.S. factories will provide these organizations with the ability to increase production and remove some of the more tedious work performed today.

4. ARM has funded several projects in this area. Can you tell us a little about them?

ARM has a large membership from the apparel and footwear industry spanning end manufacturers, equipment makers, designers and distributors. Notable members include Bluewater Defense, Hickey Freeman Co. Inc., Virbram, Interface Technologies LLC, Henderson Sewing Machine Co., Siemens, Eclo Inc, and others.

We are currently funding two paths to robotic manufacturing of garments. One uses stiffened fabric, and the other uses natural fabric. Both paths are scheduled to produce a complete garment by the end of 2021. To date, we are sponsoring a team including Interface Technologies, Rensselaer Polytechnic Institute (RPI) and Hickey Freeman to robotically sew the inseam of a pair of dress pants. We are also sponsoring a team consisting of Sewbo, Bluewater Defense, Siemens, and University of California-Berkley to stiffen a fabric, then shape, fold, align and sew a pleated pocket with flap and then sew it onto a pair of cargo shorts.

5. How can our readers learn more about the work that ARM and its members are doing in this area?

Great question! ARM is planning its second public webinar for August exactly on this topic. Our panel of members, some of which are mentioned in my earlier responses, will be sharing their insights on the industry and the impact robotics can make in apparel and flexible materials. Stay tuned for your invitation to the webinar.

ABOUT ARM

The Advanced Robotics for Manufacturing (ARM) Institute catalyzes robotics and workforce solutions to strengthen the US industrial base. Structured as a public-private partnership, ARM is funded by the Department of Defense and works with its 240+ member organizations that span government, industry, and academia to secure our nation’s future. The ARM Institute is part of the Manufacturing USA® network. Learn more at www.arminstitute.org.