ARM Institute Members are varied in their focus areas, sizes, and history, but one common thread unites each organization: a drive to build the future of US manufacturing. Each of these organizations leverages their strengths and areas of expertise to secure a brighter future for the US workforce, a stronger Organic Industrial Base (OIB), and a more resilient manufacturing economy. This impact often involves creating AI solutions for manufacturing.

Artificial intelligence (AI) has been dominating headlines. That’s one reason we launched our three-part summer AI Public Webinar series (more on that here). But AI isn’t a new field for the ARM Institute. Since 2017, we’ve catalyzed countless projects that leverage AI to improve manufacturing consistency and efficiency while minimizing cost. Our Members have been on the forefront of this field right alongside us.

In conjunction with our AI webinar series, we’ll also use this summer to highlight our members who offer AI solutions for manufacturing through our Five Question interviews. By demystifying AI best practices, accelerating AI robotic projects, and highlighting companies that are in a prime position to help manufacturers with AI, we take AI out of the theorectical realm and into tangible, practical impact.

For this month’s Five Questions feature, we chatted with Pat O’Donnell! Pat is the Founder and CEO of Shelfmark, a start-up level ARM Member. Shelfmark automates in-line visual inspection using AI for manufacturers to reduce defects, improve labor efficiency, and minimize waste.

1. We always like to start by exploring our member’s background! Can you tell us about your career journey and how it led you to Shelfmark?

Thanks for the opportunity to share our story! I am an industrial engineer by trade yet spent all my career in technology. In 2022, I was leading the local office of a software consultancy when I felt the call to entrepreneurship. I left my job with no concept of what type of company to build and spent six months doing intentional discovery with local manufacturers, distributors, and industrial companies. I sought problems that could be solved for these customers with emerging technology out of my alma mater, Carnegie Mellon.

Three common themes emerged: manufacturers could not find labor, 90% of them manually inspected the products that they produced, and every single one wanted to automate with AI, but unless you had a team of automation engineers, AI solutions in the market are not built for you. That led us to create Shelfmark: The plug-and-play AI visual inspection automation platform for all manufacturers.

2. Can you tell us about Shelfmark? What industry problems does Shelfmark address?

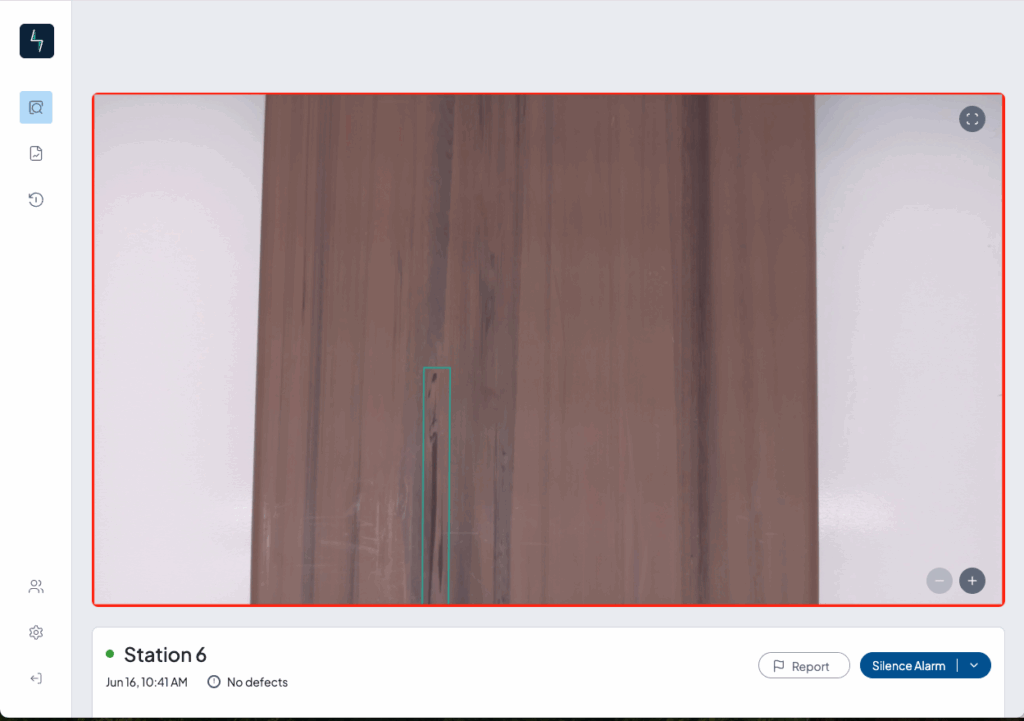

Shelfmark is the AI visual inspection automation platform for manufacturers. We provide the complete solution: hardware, software, machine learning AI, and implementation to take manufacturers from zero to in-line product inspection automation. This allows manufacturers to cut waste by up to 90%, labor costs by up to 50%, and improve quality and consistency in their product spec. Shelfmark implementations have shown a 7x ROI through automation of manual inspection tasks.

Manufacturers in industries like metals, plastics, textiles, print, or optics use Shelfmark to automate visual inspection tasks that were previously impossible to automate with classic computer vision solutions.

3. We love that Shelfmark is centered on practical AI applications. Your website states: “Shelfmark brings AI out of the lab and onto your line, so you get results, not headaches”. When organizations approach you hoping to implement AI solutions, how do you get started? What advice do you have for manufacturers looking to explore AI solutions?

Once we meet a manufacturer, our first step is always to coordinate a visit to the customer’s facility. We insist on seeing our customers’ production processes firsthand, because each facility is unique and we can better serve our customers when we have a chance to walk the floor with them. From there we can quickly scope an implementation, and in many cases, be installed in as little as a month. We aim to make the process as light of a lift as possible for our customers.

I’d advise manufacturers to work with partners that are willing to get in the weeds and own an implementation alongside you. In visual inspection, the right hardware and environment is more than half the battle. A software-only solution, or a camera that is shipped to you may set you up for failure if you’re not an expert in vision systems.

When you begin your AI journey, it’s important to start with a bite-sized initiative that can demonstrate real ROI for relatively low effort. We’re biased, but we see visual inspection as a great place to start for that reason. Success here can build confidence for larger implementations like robots, co-bots, or automated retrieval systems.

4. There are many upsides to implementing AI in manufacturing, but what are some common pitfalls manufacturers should avoid?

The biggest pitfall that we see from manufacturers is how they think about capitalization and maintenance of an AI system. AI evolves over time, which means that it may drift (get less accurate over time) or need to be retrained as you introduce new products, environments, or even experience new lighting conditions in different seasons. Many of the companies we work with are deep experts in what they do – and don’t want to have to become AI experts as well.

We encourage customers to think of AI visual inspection more like hiring the world’s best employee than buying a camera. This new ‘employee’ will require periodic retraining and a performance management plan. Consider that it may be an operational expense (OpEx) and that a vendor may be better suited to maintain its performance for you. We call our offering ‘Managed AI’ – we manage visual inspection for a low monthly cost, as opposed to a large upfront CapEx investment for the solution.

5. Shelfmark just recently joined the ARM Member Consortium. What do you hope to achieve through the ARM Institute and what do you want other ARM Members to know about your capabilities?

We’re excited to connect with forward-thinking manufacturers that hope to benefit from the introduction of AI to their operations. We’re glad to be a resource for them, even if Shelfmark isn’t the right fit for their needs. The technology in this space changes so quickly, we’re always glad to compare notes and recommend solutions. Please don’t hesitate to reach out, whether Shelfmark is a perfect fit for your visual inspection automation needs, or you just want to chat on the latest in technology, we’re glad to be a resource. I can be reached via email at [email protected].

Bonus: Is there anything else you’d like to add?

Shelfmark is proudly headquartered in Pittsburgh, PA, about a mile from downtown and two miles from ARM HQ. If you are a Pittsburgh-based manufacturer or supplier, we are always glad to host or visit and can’t wait to make deeper connections in the organization.

See Shelfmark in Action at Our 2025 Annual Member Meeting!

Shelfmark will demonstrate their work at our Annual Member Meeting in the Member Showcase Hall! The Member Showcase Hall at our Annual Meeting showcases groundbreaking innovations in robotics, AI, and workforce development to strengthen US manufacturing. Our Showcase Hall forges connections between non-traditional collaborators, paving the way for greater innovation and collaboration.

Join us at our 2025 Annual Member Meeting to explore the Showcase Hall! Our Member Meeting is our cornerstone event and our most signficant networking opportunity of the year. Representatives from across our 450+ member organization consortium join us in-person for 2.5 days of networking, collaboration, knowledge-sharing, and technology demonstrations. This year’s event will take place Sept. 3-5 in Pittsburgh, PA.

The Member Meeting is free to attend, but open only to ARM Members. Learn more here or email [email protected] for assistance registering.

Not a Member? Join by the end of August 2025 to be eligible to attend this year’s meeting.

ABOUT THE ARM INSTITUTE

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse consortium of 450+ members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and X (formerly Twitter).