In celebration of ROS-Industrial’s ten year anniversary, this month’s Five Questions piece features Matt Robinson from ROS-Industrial and SwRI (Southwest Research Institute). Matt has been an ARM Institute Member since our inception in 2017 and has participated on several ARM Institute-funded projects, working groups, and our Technical Advisory Council (TAC). Earlier this year, we recognized Matt as an ARM Institute Champion for his leadership both in terms of ARM Institute participation and industry-wide impact.

1. Let’s start with an introduction to ROS-Industrial for anyone who hasn’t worked with ROS-I. What is ROS-I and what is your role?

ROS-Industrial is an open source project, that seeks to extend ROS, the Robot Operating System, to industrial relevant hardware and applications. Southwest Research Institute started the project to address issues around industrial robotics and having to “reinvent” the wheel for the creation of new capability and to breakdown barriers to implement novel new systems regardless of the hardware selected. There has been great interest and progress in leveraging open source software to address industrial challenges, so a partner Consortium was established to provide resources and guide development of these open source resources.

I manage the Americas Consortium that seeks to provide guidance to the development of additional new open source resources and continue to provide value and tools to the Consortium membership and broader open source robotics community.

2. ROS-Industrial recently marked its 10-year anniversary. In your opinion, what are a few of the most impactful or exciting applications of ROS-I?

We are excited and humbled to have the project mark the 10-year anniversary. Some of the most successful applications have been the original production ROS-based application by Spirit AeroSystems, to perform high mix painting. The next is the recent announcement of NOV’s oil rig automation (video) solution built on ROS. This latest was just recently shared at our annual meeting and is a great example of addressing limitations in a market place through the leverage of open source building blocks, while also building a team with a passion for learning and owning a solution for the team’s benefit.

3. What’s next for ROS-I? What are some upcoming ROS-I contributions, applications, activities, or events that you’re excited about?

The two main areas of interest have been in enabling AI tools in way to enable new capability, or to improve system behavior and performance. Some examples are in the space of feature recognition influencing tool path planning and subsequent motion planning, and another is building AI frameworks to emulate complex physics-based simulation to enable optimized outcomes.

This second one is really interesting and may enable a tighter coupling of advanced product development with how things actually happen on shop floors. For instance, we do complex simulations to understand how a fabricated part may distort due to welding. However, when we get the real pieces in the factory, they often do not all match the CAD, or fit exactly as they did in that physics model. Having tools that can analyze and update plans at runtime would enable improved outcomes and greater process efficiencies.

4. You have participated in several ARM Institute-funded projects. Can you tell us a little bit about that experience and the value you’ve found participating in ARM Institute-funded projects?

ARM Institute funded projects are impactful because they bring together diverse teams comprised of academia, end-users, other solution providers, and small businesses. This dynamic enables a variety of perspectives and really allows for impactful new solutions to emerge. I have enjoyed the feedback from end-users that have evaluated ROS-I and provided feedback on areas that need improvement, such as the ease of adoption, how can we lower the barrier to enable more people to utilize ROS and ROS-I resources to solve day to day challenges.

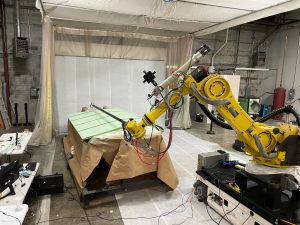

It is also great to get feedback on a completed application and then see that prior developed application evolve into a new capability. That was the case with a couple of recent projects where the A5 project, funded by AFRL resulted in two ARM Institute projects and functioning capability in Mobile Autonomous Coating Application for Aircraft Sustainment, which sought to create a mobile robotic paint solution for high-mix aerospace parts. The second, Autonomous Coating with Realtime Control and Inspection, realized real time paint process planning based on observed features and adjusting the paint process from a learning framework informed by extensive computational fluid dynamics. Seeing an existing, and still active ROS-based project turn into two different, yet related solutions, really within a year shows the power of ROS, and the ability to repurpose existing robotics software into new capabilities or applications.

5. Our 5th Annual Member Meeting will take place November 15-17, 2022. As an ARM Institute Member who has attended each of our past meetings, what value do you find in the ARM Institute Member Meeting?

I have attended every ARM Institute meeting since the first one, and it has been a real joy to see how they have evolved. The most valuable element is talking with others that are involved with working on projects and those with tangible problems in leveraging robotics in their factories. You just cannot replace those interactions. The passion for the people and teams working on the projects is truly evident when you get the chance to talk face to face, and it is great to share the project work and get the feedback from those with the current challenges today. That interaction, and dialog is the foundation for enabling robotics to evolve and make a meaningful impact on US manufacturing. The challenge is turning project work into tangible things that those with the problems can grab and leverage on their factory floors, and that is a continuing process, but one that it feels like we are making progress on each time we get back together, and we look forward to supporting the Annual Member Meeting again this November.

Learn More

The Annual ARM Member Meeting is free to attend, but only open to ARM Institute Members. Email [email protected] to learn more about membership or for help registering for our event.

Join Our Mailing List

About the ARM Institute

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse ecosystem of 300+ consortium members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and Twitter.