When Jay Douglass, ARM Institute Chief Operating Officer, started building out the ARM Institute directly following its inception in January 2017, he didn’t realize he would one day work on the same site where Robert Patterson Douglass, his great, great uncle worked. The ARM Institute’s Pittsburgh offices are housed under the skeleton of an old steel mill that stands where the Jones & Laughlin (J&L) Steel Mill once operated. Inside, a team of experts works to solve the critical issues inhibiting the growth of manufacturing in the U.S., from workforce needs to robotics technology development.

A Snapshot of Mill 19’s Historical Significance

When the ARM Institute moved into its Mill 19 offices in 2019, the Institute inherited a storied site that was previously home to the Jones & Laughlin (J&L) Steel Mill where Jay’s Great, Great Uncle Robert Douglass once worked. J&L built their first industrial plants along the Monongahela River in 1883, creating a hub with plants on Pittsburgh’s South Side and in the Hazelwood neighborhood connected by the Hotel Metal Bridge. This industrial hub was so critical to the nation’s steel production that the Hot Metal Bridge, which still stands near the ARM Institute’s Mill 19 offices, was the second most heavily guarded piece of infrastructure in the United States during World War II.

Between the two locations, the J&L plants employed around 12,000 workers. Only 3,600 workers remained when the Ling-Temco-Vought Incorporation (LTV) bought the site in 1974 as the steel industry started to collapse. The plant closed operations in 1997.

For years, the site remained empty until it was purchased by a group of Pittsburgh foundations under the name Almono LP. RIDC, working with Almono LP, began site remediation in 2002. In 2017, the ARM Institute, Carnegie Mellon University, and Catalyst Connection were named as the site’s first anchor tenants with Motional and OneValley later adding locations to the site. The site’s visible transformation into a state-of-the-art R&D hub illustrates a larger history of Pittsburgh’s transformation into a world leader in robotics development.

Jay’s Connection to Mill 19

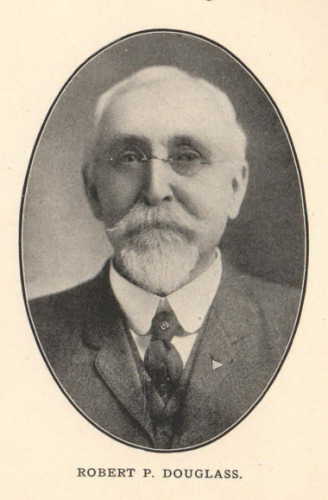

The site also holds personal significance for Jay. For 30 years, his Great, Great Uncle Robert Douglass worked as a Superintendent of Labor in the Eliza Furnaces of the J&L Steel Company. In this role, Robert Douglass managed labor relations at the steel mill by representing workers’ needs, ensuring steel mill productivity and safety, and taking on critical operational tasks to ensure the economic competitiveness of the mill.

Beyond location, Jay’s role shares many similarities with Robert’s story. Jay drives the ARM Institute’s operations – from membership ecosystem building to the Institute’s engagement with the Hazelwood community. He was the ARM Institute’s first employee and built a team of experts who direct the future of U.S. manufacturing through technology and workforce development on the same site where Robert worked.

Robert Douglass also served as a Private during the Civil War. Today, Jay’s work at the ARM Institute ensures the safety of modern day U.S. warfighters. In collaboration with the Department of Defense, the ARM Institute identifies critical needs in U.S. manufacturing that not only puts the nation’s economic preparedness at risk but pose a risk to our national security and warfighters. The ARM Institute addresses these needs in many ways, including catalyzing technology and workforce projects.

The ARM Institute’s Work in Hazelwood

Beyond its national mission, the ARM Institute also engages with Pittsburgh’s Hazelwood neighborhood. Like many other regions around the country, the Hazelwood community suffered economic disarray, job loss, and a decrease in neighborhood population when the steel mills closed. Had Robert lived in a different time period, his role too would have been eliminated and his future compromised by this job loss.

In present day, the ARM Institute works with Hazelwood community leaders to showcase the increasing importance of manufacturing in the U.S. and the reality that manufacturing jobs of today are safer, more accessible, and more stable than ever before thanks to advanced technologies like robotics and artificial intelligence (AI). Jay leads this effort to engage and support the Hazelwood Community, from opening our doors for community tours to hosting children’s robotics and AI workshops with regional partners.

Don’t Miss Another Update –

Join our Mailing List

About the ARM Institute

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse ecosystem of 300+ consortium members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and Twitter.