ARM Institute’s Robotics Manufacturing Hub Delivers Free Proof-of-Concept for Keystone Ridge Designs, Leading to Robotics System Installation

Learn how our team helped Keystone Ridge Designs, a leading manufacturer of commercial site furnishings, adopt a new robotics solution using our free services.

If you’ve ever sat on a bench, tossed trash in a receptacle, or gathered around a table in a public space—whether at a park, university, retail center, downtown streetscape, or corporate campus—you’ve likely used many of the commercial site furnishings manufactured by Keystone Ridge Designs. Headquartered in Butler, Pennsylvania, Keystone Ridge Designs has been transforming outdoor spaces across the country with its extensive collection of benches, litter receptacles, table sets, bike racks, planters, and more. With almost 30 years of growth and experience, Keystone Ridge Designs remains one of the many small to medium-sized manufacturers that power our nation’s economy.

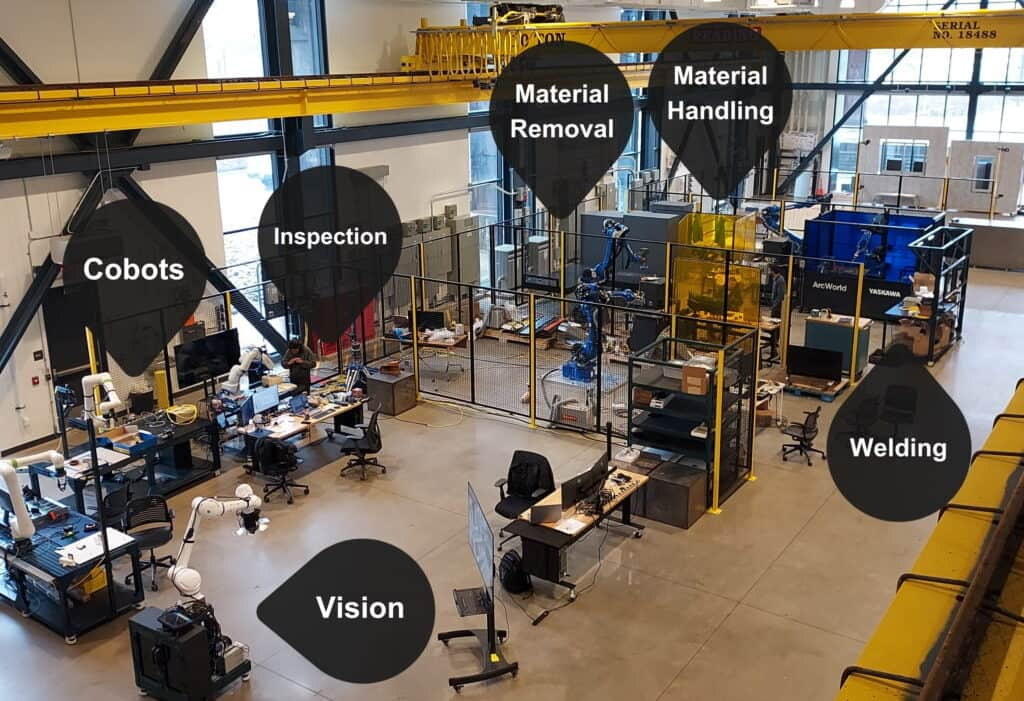

Recently, Keystone Ridge Designs wanted to explore how robotics might be able to further enhance their manufacturing competitiveness, but they weren’t sure where to start. Catalyst Connection, an ARM Institute Member and one of our fellow New Economy Collaborative partners, connected the manufacturer with our Robotics Manufacturing Hub team and invited them to attend the free workshop on robotic sanding and finishing that the ARM Institute and Catalyst Connection co-hosted in the late spring of 2024. After hearing from fellow manufacturers about adopting robotics at the workshop and seeing demonstrations in the Robotics Manufacturing Hub, Keystone Ridge Designs was sold – they were ready to see how robotics could help them.

Thanks to the ARM Institute’s Robotics Manufacturing Hub program, they were able to leverage free services to power their automation journey and support them through the installation of their new robotics system.

“Working with the ARM Institute was quite literally the handshake we needed. That handshake acted as the catalyst for the introductions to vendors who possessed the professional and technical expertise to help us turn our ideas into a reality.” – Mike Lippmann, Plant Manager at Keystone Ridge Designs

Dive deeper into how we worked with Keystone Ridge Designs below.

Automation Assessment:

Following their participation in our workshop, the Robotics Manufacturing Hub team completed a site visit to Keystone Ridge Designs, during which our team familiarized themselves with the manufacturer’s current processes, talked to team members, and understood what was working well and what could be improved.

From there, our team completed a free automation assessment that detailed their findings, noting where robotics and automation may be able to play a role and, equally importantly, where it would not be worth investing in robotics. Our team’s primary finding centered on a robotic solution for the welding and grinding of welded parts. This area was ripe for an automated solution; a robotic solution would be well-positioned to be a great fit to both help Keystone Ridge Design’s workforce and to further improve the quality of their products. With quality at the forefront of their mission, Keystone Ridge Designs wanted to be sure that any robotic solution would be able to at least match the quality that put them on the map.

Proof-of-Concept:

Next, the Robotics Manufacturing Hub team completed a free proof-of-concept demonstration for robotic welding and robotic grinding of welded parts. At no cost to the manufacturer, the Robotics Manufacturing Hub team tested and compared grinding finish results of different abrasive, force, and speed combinations along with robot path planning to not only adapt a manual process to an automated process, but also physically show that the desired quality of finish can be achieved through robotics.

Next, the Robotics Manufacturing Hub team completed a free proof-of-concept demonstration for robotic welding and robotic grinding of welded parts. At no cost to the manufacturer, the Robotics Manufacturing Hub team tested and compared grinding finish results of different abrasive, force, and speed combinations along with robot path planning to not only adapt a manual process to an automated process, but also physically show that the desired quality of finish can be achieved through robotics.

The ARM Institute also compared the results of manual welding vs those achieved with robotic welding. This work resulted in a highly interactive and hands-on half day in the Robotics Manufacturing Hub at the ARM Institute’s Pittsburgh headquarters, during which Keystone Ridge leadership and employees saw the results of the proof-of-concept and got hands-on with the robot teach pendant, ensuring that the Keystone Ridge workforce was familiar and ready to work with the proposed robotic solution. The team enthusiastically signed off on moving forward with the solution.

This work was completed entirely for free and did not require a commitment from Keystone Ridge Designs to install the system. By providing a free proof-of-concept to manufacturers, the Robotics Manufacturing Hub program removes the perceived risks associated with robotics and automation.

RFP Process & System Installation:

After the team at Keystone Ridge Designs signed off on the proof-of-concept, the Robotics Manufacturing Hub team supported the manufacturer by managing the request for proposal (RFP) process for the integration services needed to install the system. Acting as a neutral, third-party expert on behalf of Keystone Ridge Designs, the Robotics Manufacturing Hub team completed a document outlining the technical requirements for the approved robotic solution and sent the RFP to the institute’s network of robotics integrators. After obtaining several quotes, the Robotics Manufacturing Hub and Keystone Ridge teams worked collaboratively to evaluate the responses and select the best fit for the robotics integration.

The manufacturer opted to work with ACT Robots and ensured that the resulting proposal included the exact equipment that they saw, tested, and approved at the ARM Institute’s Robotics Manufacturing Hub. Keystone Ridge Designs ended up investing around $300,000, installing a workcell comprised of a Yaskawa GP-88 Robot with a PushCorp spindle and compliance device.

By working with Robotics Manufacturing Hub experts, Keystone Ridge Designs minimized the time that their internal team spent exploring robotics, ensured that the proposed solution would work for them, and received support on the RFP and installation process. With the Robotics Manufacturing Hub acting as a neutral expert, Keystone Ridge Designs was able to successfully navigate their automation journey and enhance their manufacturing competitiveness.

Benefits for ARM Members & Robotics Manufacturing Hub Partners:

The manufacturer wasn’t the only company that benefited from this project. By providing equipment to the ARM Institute, Yaskawa and Pushcorp, both ARM Institute Members, were able to showcase their equipment, leading to a sale when the proof-of-concept was approved. Additionally, robotics integrator ACT Robots was able to connect to a new customer.

The manufacturer wasn’t the only company that benefited from this project. By providing equipment to the ARM Institute, Yaskawa and Pushcorp, both ARM Institute Members, were able to showcase their equipment, leading to a sale when the proof-of-concept was approved. Additionally, robotics integrator ACT Robots was able to connect to a new customer.

Plus, with a consistent pipeline of manufacturers interested in leveraging the Robotics Manufacturing Hub combined with a packed tour schedule at our headquarters, partners who provide the ARM Institute with equipment are regularly connecting both with manufacturers and a variety of stakeholders and VIPs.

Thank you to Yaskawa, FANUC, PushCorp, ORBBEC, Denso, and others for providing equipment to the Robotics Manufacturing Hub.

Interested in providing equipment to the Robotics Manufacturing Hub or joining our robotics integrator network? Let us know by emailing [email protected].

Free Services for Manufacturers in Southwestern Pennsylvania Region:

Our Robotics Manufacturing Hub is a federally funded, free service for small and medium sized manufacturers in the Pittsburgh region (defined as the following counties: Allegheny, Armstrong, Beaver, Butler, Cambria, Fayette, Greene, Indiana, Lawrence, Washington, and Westmoreland counties). As a free service part of the Southwestern Pennsylvania New Economy Collaborative, our team will work with you to complete a free automation assessment, help you understand where robotics can strengthen your operations, prototype robotics solutions at no cost with no commitment to installation, and help you find a path forward to full integration on your manufacturing floor if you choose to do so.

Why work with us? Our Robotics Manufacturing Hub acts as your free manufacturing research and development department. We’re not selling you services, but rather acting as an extension of your team to improve your global competitiveness and help you understand where robotics can play a role. We’ll help you get hands-on with robotics equipment you may otherwise not be able to access and prepare your workforce to work with a selected solution. We don’t do this alone – the Robotics Manufacturing Hub leverages the ARM Institute’s national consortium of 450+ member organizations comprised of key robotics and manufacturing experts.

By working with our team, you can be sure that the robotics solution you select will provide you with the highest possible return on investment.

Get Started with Robotics at No-Cost

Complete our form below to connect with our team and see how you can leverage our no-cost resources to prototype robotics for manufacturing solutions that fit your operations! One of our representatives will be in contact with you shortly after you complete the form.

Not sure if you qualify or looking for additional information? Contact us [email protected]. If you’re interested in our services but do not qualify for free services under the limitations listed above, reach out to use at [email protected] and we’ll explore how we can work with you!

Get Started with the Robotics Manufacturing Hub

ABOUT THE ARM INSTITUTE

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse consortium of 450+ industry partner across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, with a satellite office in St. Petersburg, FL, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and X (formerly Twitter).