ARM Institute Project Highlight:

Securing the Digital Backbone with Corsha’s Zero-Trust Platform for Machines

Project Team:

Corsha, led by Principal Investigator Anusha Iyer – CEO of Corsha

Background

In March 2023, in partnership with the Office of the Secretary of Defense Manufacturing Technology (OSD ManTech) and the ARM Institute’s fellow Manufacturing Innovation Institutes (MIIs), the ARM Institute hosted a workshop at our facility in Pittsburgh centered on Point of Need Manufacturing Challenges for the Defense Industrial Base. This event included an OSD-led Requirements Workshop and pitch presentations from MII project teams that were selected from the associated MII Point of Need Manufacturing Challenge Project Call.

The ARM Institute’s project, Securing the Digital Backbone with Corsha’s Zero-Trust Platform for Machines, with ARM Member Corsha was selected for funding through this Project Call. The Project Call centered on a singular scenario: U.S. forces are engaged in an operation at an austere forward operating base (FOB) in a remote location and have no access to normal logistics support. Manufacturing at the FOB will provide capabilities and sustain personnel and equipment to successfully complete their operation, but will require systems to operate under extreme conditions of temperature and humidity.

Because the reach of the U.S. forces is global, teams were tasked to demonstrate their projects at either an extreme cold weather (i.e. arctic-type) location or an extreme hot/humid location, accounting for both scenarios. Closer to their demonstration date, the Corsha team was assigned to an arctic environment in Hanover, New Hampshire, and challenged to demonstrate their capability in frostbite-level temperatures. The Corsha team had six months to complete this project before their demonstration in December 2023.

Technical Approach

Corsha’s project demonstration centered on deploying their platform protecting access to a robotic arm at the point of need, which meant adapting all hardware and systems to be ruggedized and cold-hardy. The Corsha system would demonstrate regulated access to a tabletop FANUC Robotic Arm but also controlled, Zero Trust access to a shared artifact repository. This ability to securely cross OT and IT networks and enable trusted communication between all machines that are part of the manufacturing cell is one of Corsha’s key differentiators. Corsha provides an essential layer of cybersecurity to manufacturing systems, whether the system is a robotic arm in the field, an artifact repository in a datacenter, or workload in the cloud. As communication and data movement from OT equipment at the PoN to IT applications and the cloud and back again are becoming the status quo, seamless and uniform cybersecurity solutions like Corsha are key to protecting an ever growing and dynamic landscape.

Impact & Project Demonstration

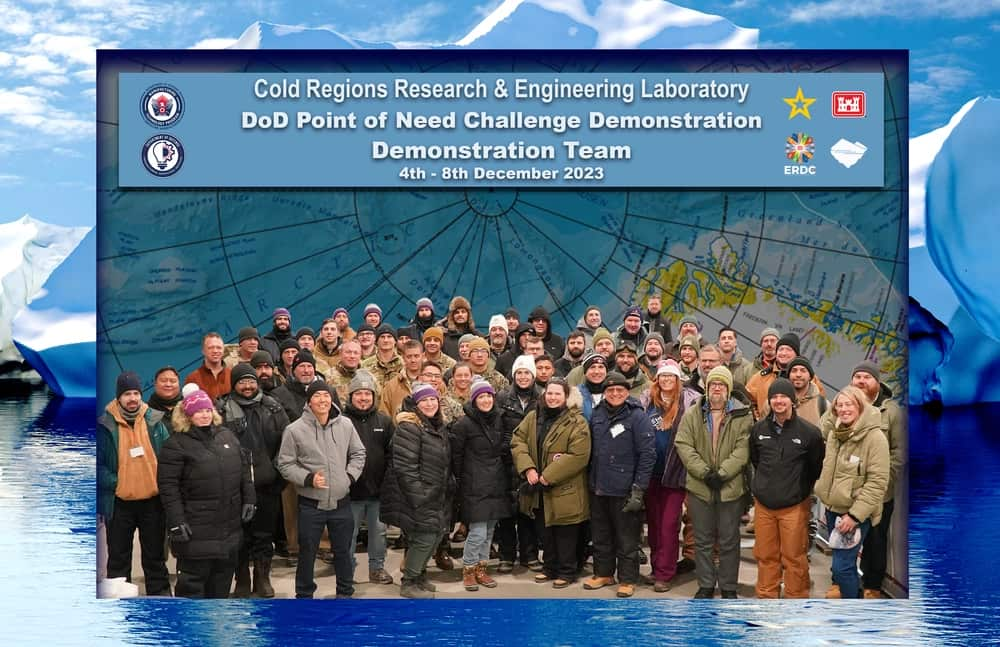

In December 2023, the Corsha team traveled to Hanover, New Hampshire to demonstrate their manufacturing and cybersecurity solutions at the austere edge, just six months after being funded. The demonstration took place at the US Army Corps of Engineers Cold Regions Research and Engineering Laboratory (CRREL) in temperatures that ranged from -40 and 30 degrees Fahrenheit. The Corsha system was able to sustain prolonged cold soaks and temperature swings, all while maintaining the essential security functionality.

“Cybersecurity in manufacturing environments is oftentimes an afterthought, especially when operating at the Point of Need. These environments are the most susceptible to cyberattacks, and the inability to effectively share data significantly slows down operations,” said Eric Kumar, Head of Customer Success at Corsha. “At the demonstration, Corsha was able to successfully demonstrate secure remote teleoperations and data sharing with multiple different manufacturing systems in real-time. This was all done by integrating with current manufacturing equipment without any product modification – a critical requirement in manufacturing. We are seeing cybersecurity be an enabler for connectivity in the manufacturing world, a key stepping stone to Industry 4.0.”

“We don’t fight alone”, said Army Maj. Gen. Gregory Knight, the Vermont National Guard’s Adjutant General. “The partnerships are key.”

Later in December during the 2023 Defense Manufacturing Conference, the Corsha team also had the opportunity to showcase their capability to Ms. Heidi Shyu, the Under Secretary of Defense for Research and Engineering (OUSD(R&E)).

This project, the associated project call, and the Point of Need Workshop that took place at the ARM Institute’s facility in Pittsburgh, PA epitomize the importance of the Department of Defense funded Manufacturing Innovation Institute (MIIs) in catalyzing critically needed solutions. Through the MIIs, including the ARM Institute, subject matter experts across industry, government, and academia can more easily collaborate. With more than 400 member organizations nationwide, the ARM Institute brings critically needed awareness to collaborators that may otherwise have failed to connect.

Help us build the future of U.S. manufacturing

The ARM Institute catalyzes collaboration across industry, government, and academia to strengthen U.S. manufacturing through robotics, artificial intelligence (AI), and workforce innovation. ARM Institute funded projects, like the one described above, are just one way we’re securing a brighter future for U.S. manufacturing. Our capabilities include project funding and management, ecosystem networking and collaboration, robotics technology development, manufacturing workforce development through RoboticsCareer.org and other capabilities, and so much more.

Join our consortium of 400+ member organizations today to work with us on this important mission. Explore membership here or email us at [email protected].

Join our mailing list

ABOUT THE ARM INSTITUTE

The ARM (Advanced Robotics for Manufacturing) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse ecosystem of 400+ consortium members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, with a satellite office in St. Petersburg, FL, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and X (formerly Twitter).