The teach pendant is the most common method to operate, control, and program industrial robots today. Despite its prevalence, current teach pendants for industrial robots are vendor specific and do not usually work with additional sensor inputs such as machine vision and force/torque sensors. There are now widely available open-source robotics software performing complex tasks, ranging from motion planning to sensor guided motion. Unfortunately, these capabilities are not readily incorporated into teach pendant operations, unless the robot vendor chooses to take the initiative. This project aims to bridge this gap by developing an open-source teach pendant.

This project offers traditional pendant functionalities such as touch screen interface, joint and Cartesian space jogging, teach and playback of waypoints, and path interpolation. At the same time, this new teach pendant offers a high-level programming environment that can leverage capabilities from the open-source robotics software ecosystem.

Specifically, this teach pendant is designed to work with robots from different vendors, allows intuitive visual programming tool such as Blockly, offers advanced features such as collision free path planning, sensor guide motion for visual servoing and compliance force control, and customizable user interface.

Project Team Participants

Rensselaer Polytechnic Institute (PI), Wason Technology, Raytheon Technology Research Center, GE Global Research, Southwest Research Institute

Approach

This project aims to develop an open-source teach pendant for use with robots and sensors from multiple vendors. The underlying software architecture is based on the open-source middleware system, Robot Raconteur, developed by Wason Technology, together with a restricted Python dialect, called Python Restricted Industrial (PyRI). The project consists of two components: a hand-held teach pendant that operator uses for teleoperation, programming, and visualization, and a run-time computer that interfaces to robots and sensors, and coordinates the functionalities through plug-in software modules in the PyRI environment.

This project aims to develop an open-source teach pendant for use with robots and sensors from multiple vendors. The underlying software architecture is based on the open-source middleware system, Robot Raconteur, developed by Wason Technology, together with a restricted Python dialect, called Python Restricted Industrial (PyRI). The project consists of two components: a hand-held teach pendant that operator uses for teleoperation, programming, and visualization, and a run-time computer that interfaces to robots and sensors, and coordinates the functionalities through plug-in software modules in the PyRI environment.

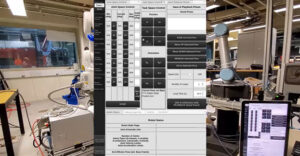

This project has developed two prototype hand-held teach pendants: Microsoft Surface Pro and Raspberry Pi-4 with a touchscreen. They use Pyodide (Python for browsers) to provide customizable UI layout within standard browsers. The run-time computer draws on open-source software Tesseract developed by Southwest Research Institute for advanced features such as collision avoidance and motion planning. This project provides all software in open source, physical 3D-printed teach pendant design, and tutorial materials. Industrial participants from Raytheon and GE have started using the project results in simulated environments and are providing feedback to guide the project development.

Results

This project has developed two prototype teach pendants (based on Microsoft Surface Pro and Raspberry Pi-4 with a touchscreen) connected to a run-time computer. The demonstrated teach pendant capabilities include robot jogging in joint and Cartesian space, save and playback of waypoints, touch screen and joystick control, same user interface for different types of robots (physical and virtual), easy programming with Blockly, robot motion with collision avoidance, vision-guided motion, and visualization preview of robot motion. The project software is entirely open source and available on GitHub. The current system has been tested with ABB 1200, Sawyer, UR5 robots, and multiple camera inputs.

Next Steps

The project has now developed working prototypes of the open source teach pendant. The next step is to increase the diversity of robots and sensors the teach pendant can support, and broaden the range of plug-in programs. The team will also embark on training and tutorial programs to increase awareness, and encourage adoption and improvement.

The ARM Institute’s role in making this project successful

The ARM Institute’s support of this project is critical to bring the concept of open-source teach pendant to reality. ARM Member community meetings and forum have fostered interaction and discussion about industrial needs of this technology, which then led to the formation of the project team. The ARM Institute provides the funding for this project, with significant cost sharing from NYSTAR of New York State. ARM Institute project management is highly supportive to help address challenges and issues, especially during the global pandemic.

ABOUT THE ARM INSTITUTE

The Advanced Robotics for Manufacturing (ARM) Institute accelerates the development and adoption of robotics technologies that are the foundation of every advanced manufacturing activity today and in the future. The Institute leverages a unique, robust, and diverse ecosystem of partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen the U.S. economy and global competitiveness, and elevate our nation’s security and resilience. Founded in 2017 in Pittsburgh, PA by Carnegie Mellon University and operating as an independent public-private partnership sponsored by the Department of Defense, ARM is part of the DoD Manufacturing USA® network. Learn more at www.arminstitute.org, follow @ARM_Robotics on Twitter or ARM Institute on LinkedIn.