Project Team

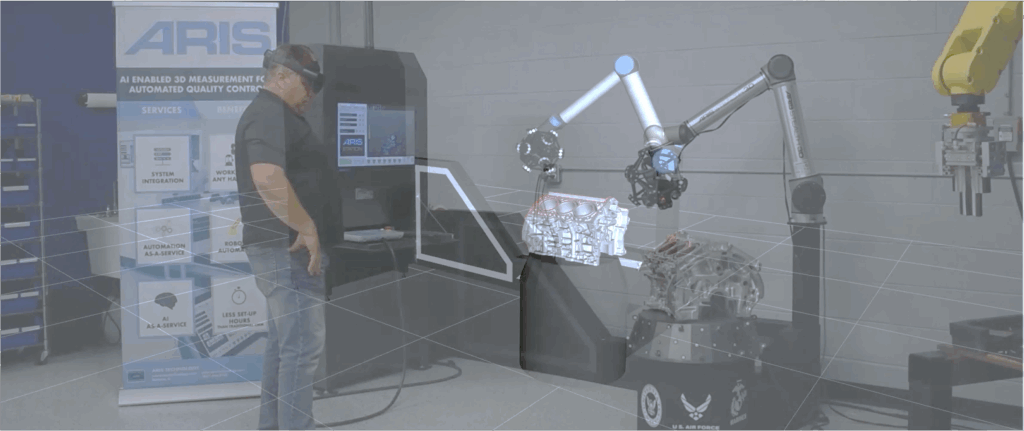

ARIS Technology (Principal Investigator), G.C. Laser Systems, and FANUC

Background

This technology project was selected from the ARM Institute’s 25-01 Core-Funded Tech Project Call that addressed the following special topic areas:

- Rapid Re-Tasking and Robot Agility

- Multi-Robot, Multi-Human Collaboration

- Adaptive Real-Time Path Planning and Control

In addition to these Special Topic Areas, the ARM Institute, in collaboration with the institute Technical Advisory Committee (TAC), government partners, and other consortium experts, outlined the following manufacturing areas of interest that project teams were encouraged to leverage as example use cases: (1) casting and forging, (2) manufacturing of hypersonics, (3) manufacturing of energetics, (4) manufacturing of garments and other textile goods, and (4) robotic inspection in confined spaces.

Project Description

Non-contact 3D scanning is a powerful tool for 3D inspection. When it is integrated into a robotic system as an End-of-Arm-Tool (EOAT), it can capture 3D data in mesh or point cloud format without contacting the surface. However, when dealing with convexity, numerous problems arise, including the inability to measure as deep as the inner diameter. Commonly, both the scanner and the robot arm are too large to reach convex regions. This project team will work address this gap through the development of an end-to-end process from robotic surface 3D scanning, localization, agile in-hole 3D scanning, and sensor data fusion.