Project

This project built an advisor robotic platform that will provide comprehensive parts inspection of complex metallic components and high-fidelity recommendations for defect identification and characterization. Currently, there is no commercially available reliable advisor robotic inspection system because high reflectivity and the complex geometry of parts hinder accurate characterization of surface profiles. While the project focuses on application in the aerospace market, the results also have the potential to impact automotive, agriculture, and consumer goods markets.

Objective

Improve visual and dimensional inspection for complex metallic components, while accelerating speed of inspection and quality.

Technical Approach

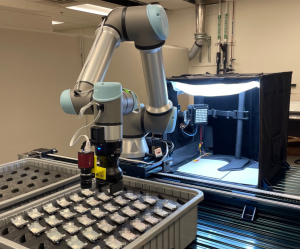

The team’s central innovation is that fusing noncontact imaging data – robotically collected at the right positions and in the right environment – enables high-quality, consistent surface profiling at required operation speeds. From there, machine-learning based data analytics continuously improves inspection performance using accumulated data. Read more here.

Impact

The ARM-Funded technology Project “Automated Defect Inspection for Complex Metallic Parts” has yielded impressive results, including detection rates above 95%, a speed of approximately one minute per part, and an expected 345% return on investment if deployed at one site. GKN Aerospace is adopting the technology, and has already built the developed inspection cell in a factory.

Using only very limited aerospace data, the team achieved consistent detection rates above 95% – beyond conventional human limits in precision inspection. The developed inspection robot also works at an impressive speed of approximately one minute per part, amplifying the throughput rate by more than three folds. Collectively, the developed robotic inspector is expected to yield a 345% return of investment if deployed at one site. Furthermore, the number is expected to increase to 1870% if the technology is scaled up to 8 sites, or 3012% at 20 sites. The return of investment could be 17 months, or as small as 2 months if scaled to 20 sites.

The team not only engineered automated data collection and the inspection AI to the performance limit, but also made scientific inquiries to create and control the source of illumination, so that even when environmental disturbances occur, lighting remains consistent at the location of the part.

These highlights are only elements from a large set of potentially game-changing impacts. A visual-centric data flow is also immediately interpretable for human-robot collaboration, and traceable to other process steps from machining to polishing, leading to cost-effective implementation and quality assurance in the production of entire engines and aircrafts.

Participants

University of Washington (Principal Investigator), GKN Aerospace