Automated Characterization in PPE Manufacturing Project Background

In spring 2020, the ARM Institute in partnership with the Department of Defense released a special COVID-19 Project Call. The ARM Institute membership responded to this call with robotic solutions to mitigate the COVID-19 pandemic and respond to future disasters. This robotics project was funded through this call.

The ARM Institute rapidly responded to the Department of Defense’s need to address COVID-19 by forming numerous national teams, drawing from diverse industries and technologies to address the myriad of supply chain shortages, particularly within PPE manufacturing. This is highlighted by a few of the key statistics listed below:

- Rapid contracting with 45 days from the Project Call release to project start

- Projects executed in 12 months

- 13 states and Puerto Rico engaged

- 23 unique organizations participated across the nine projects

Automated Characterization in PPE Manufacturing Project Objective

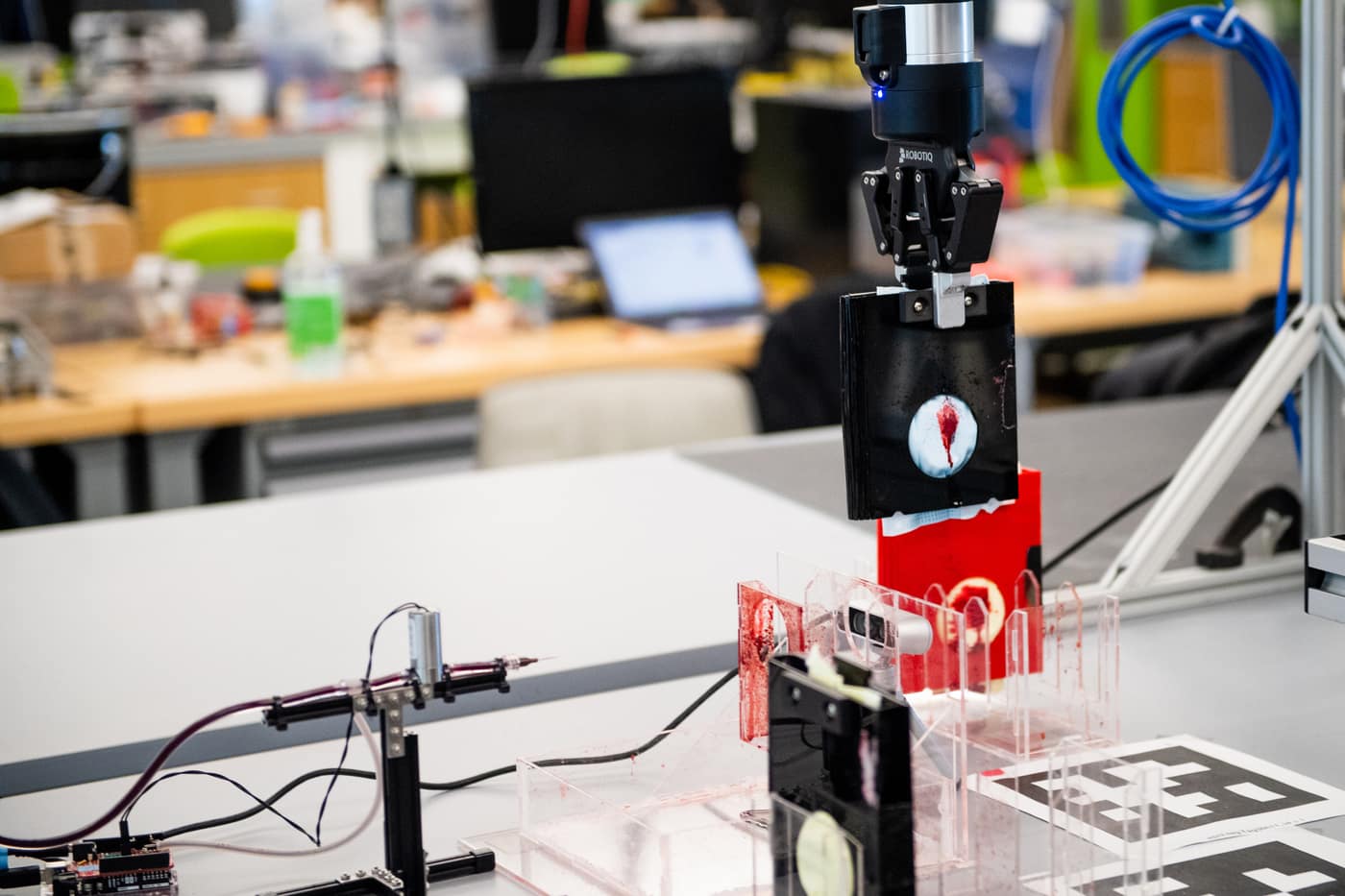

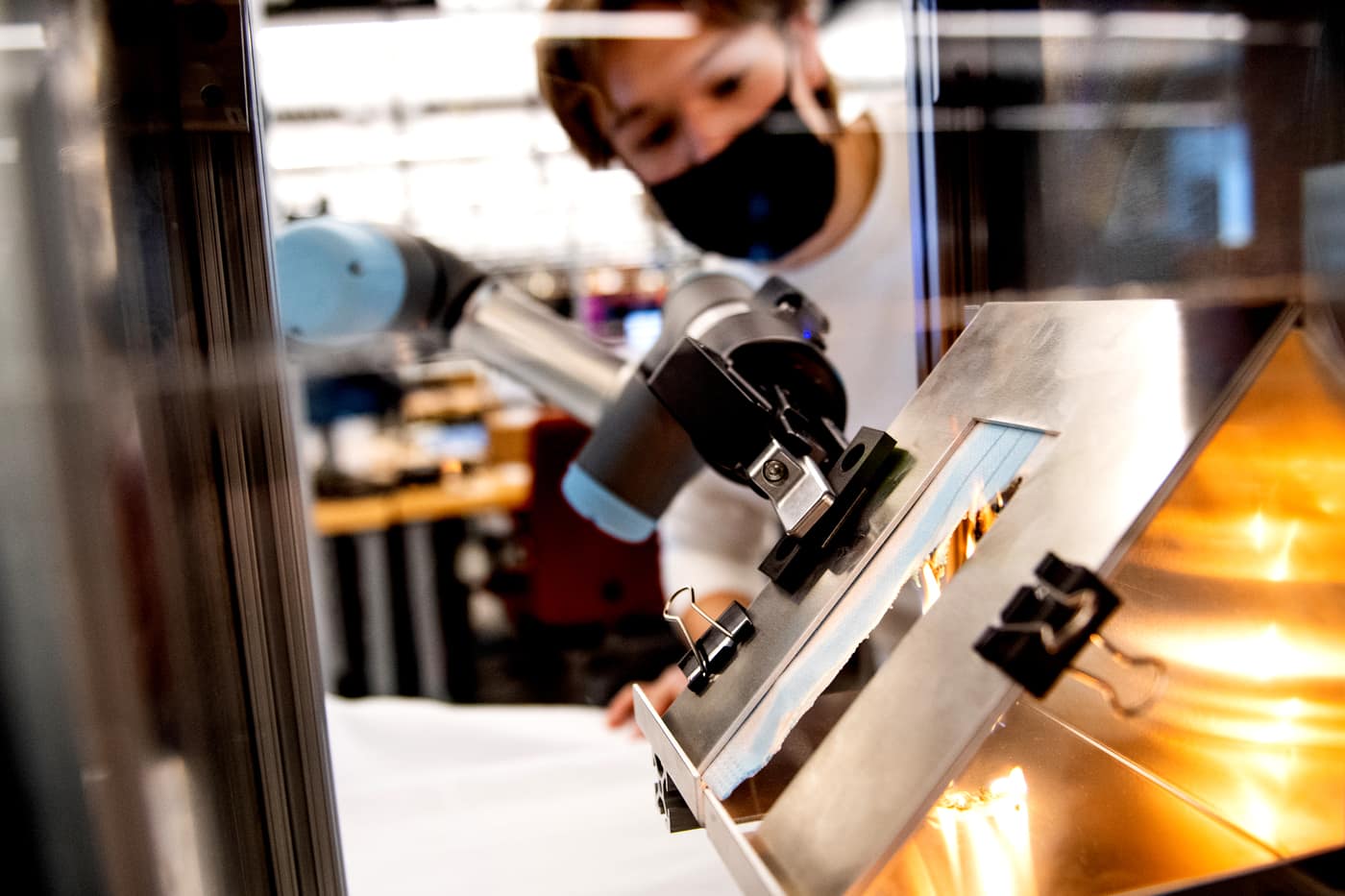

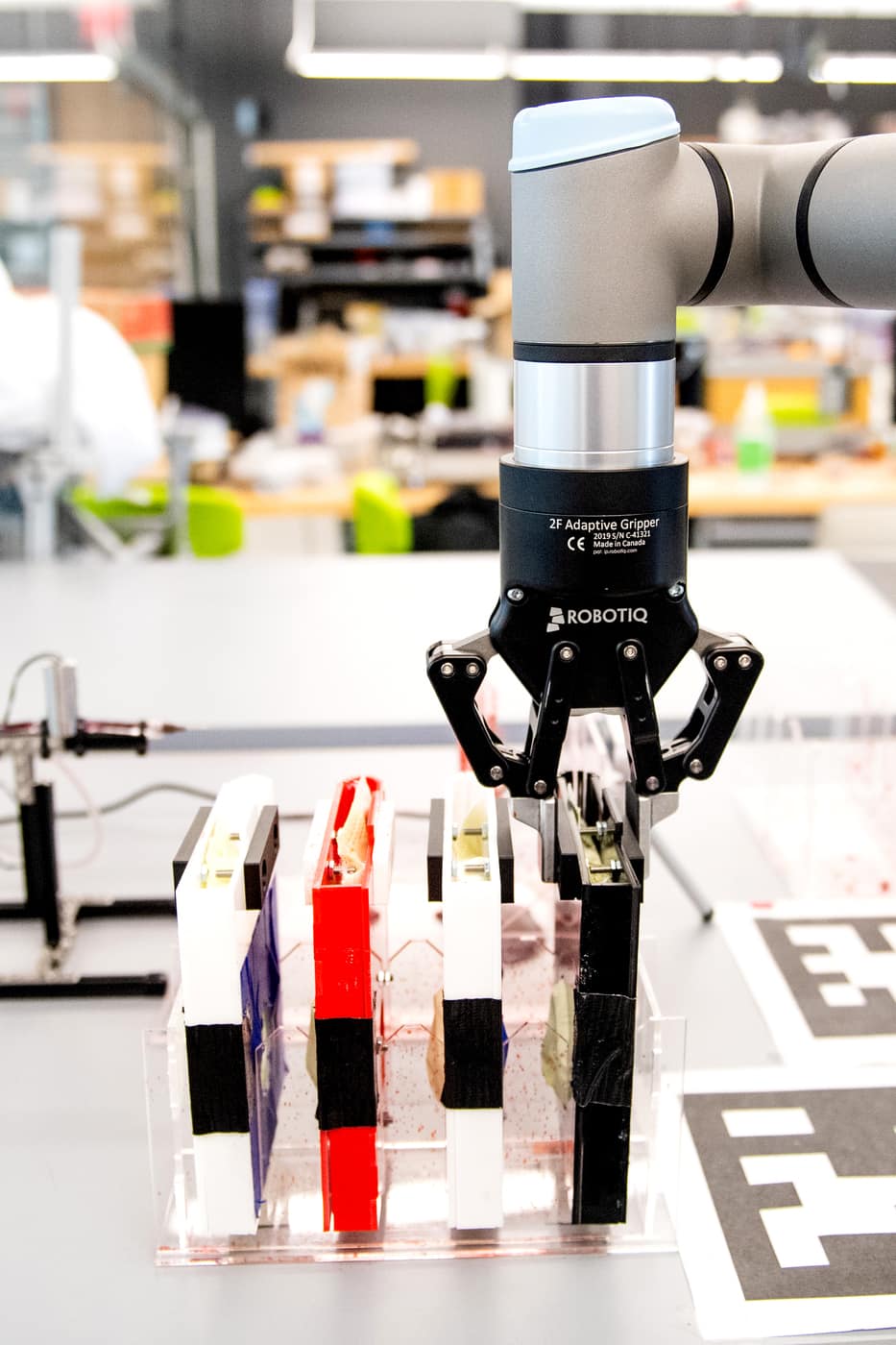

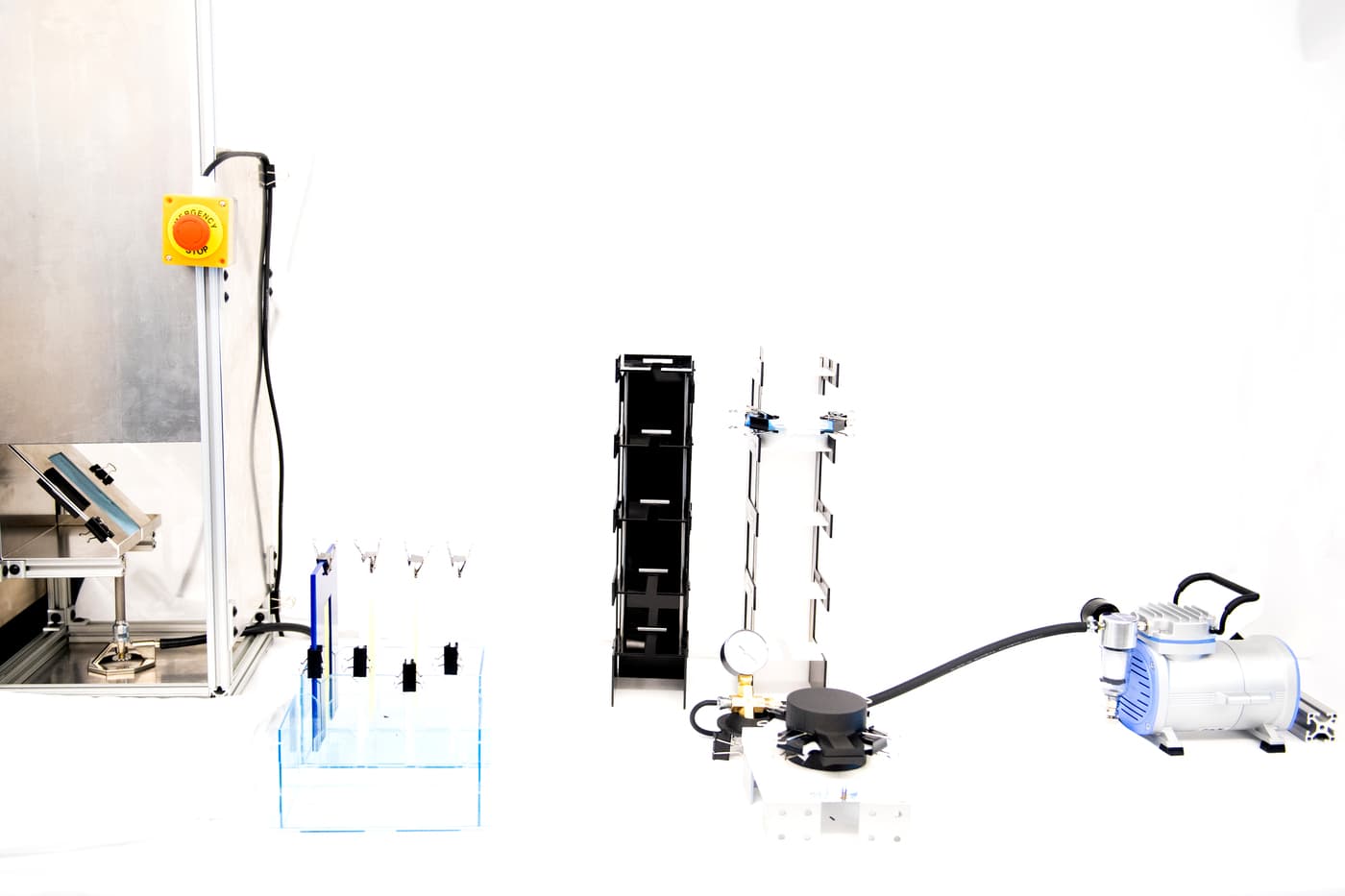

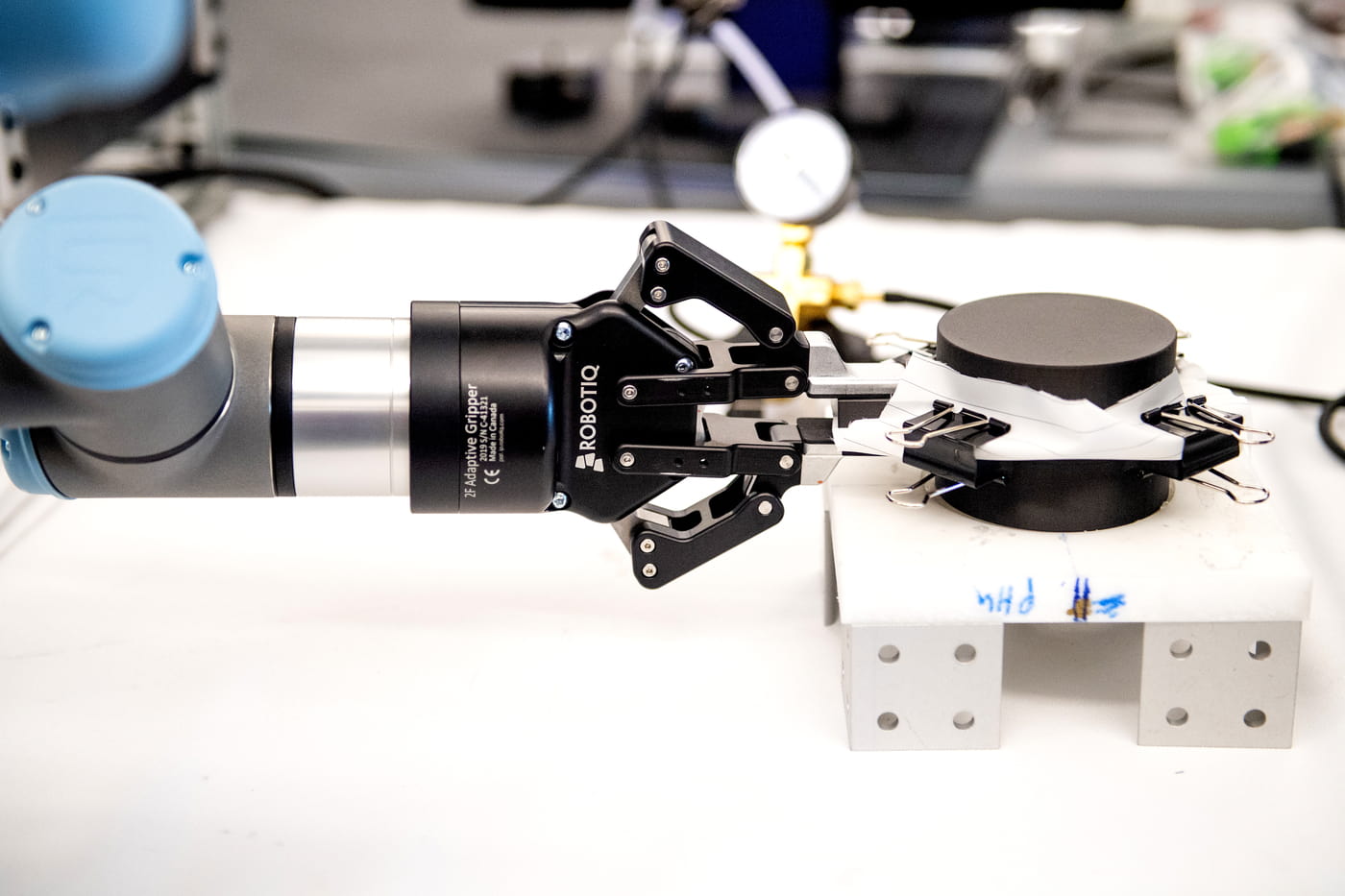

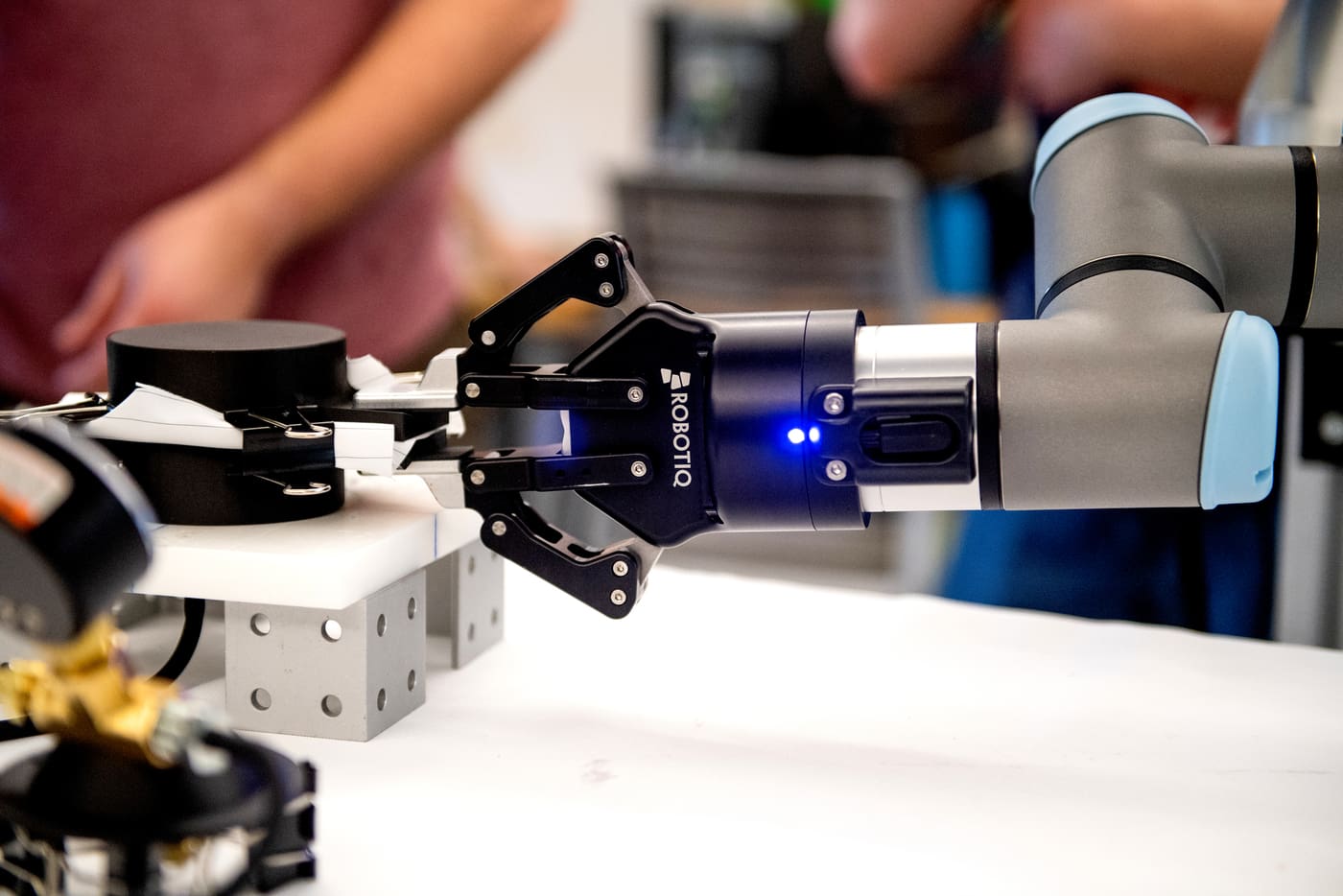

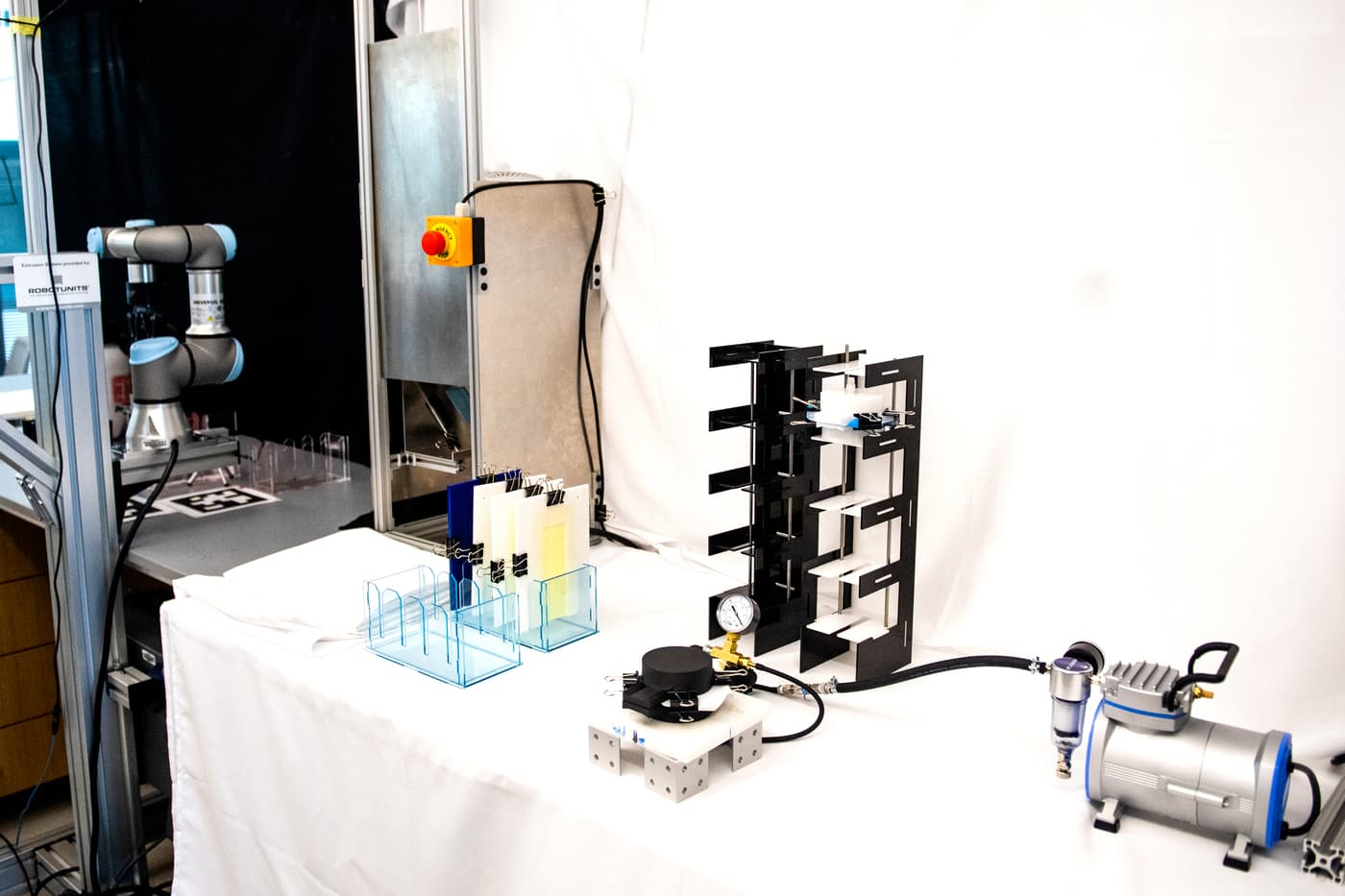

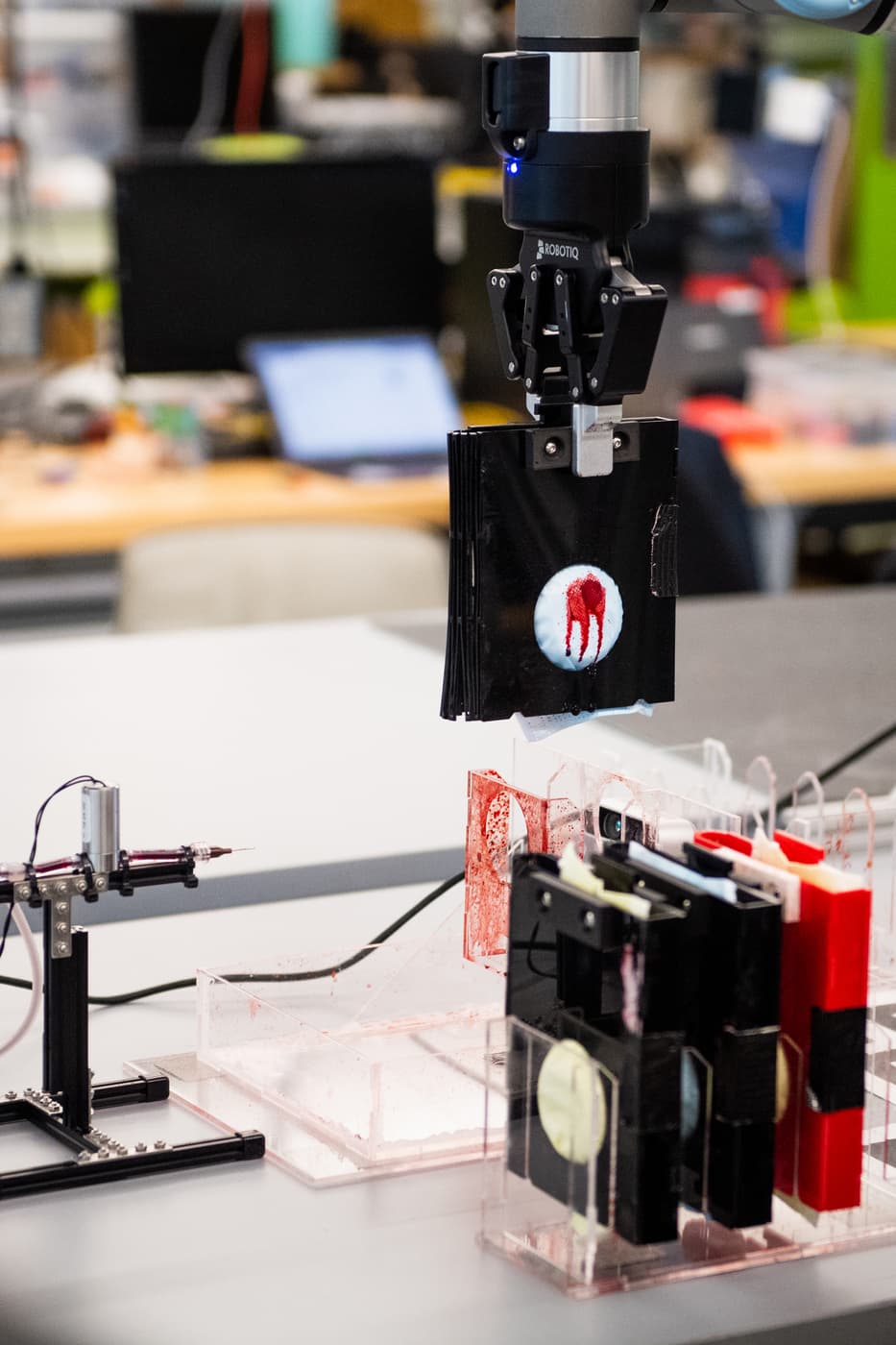

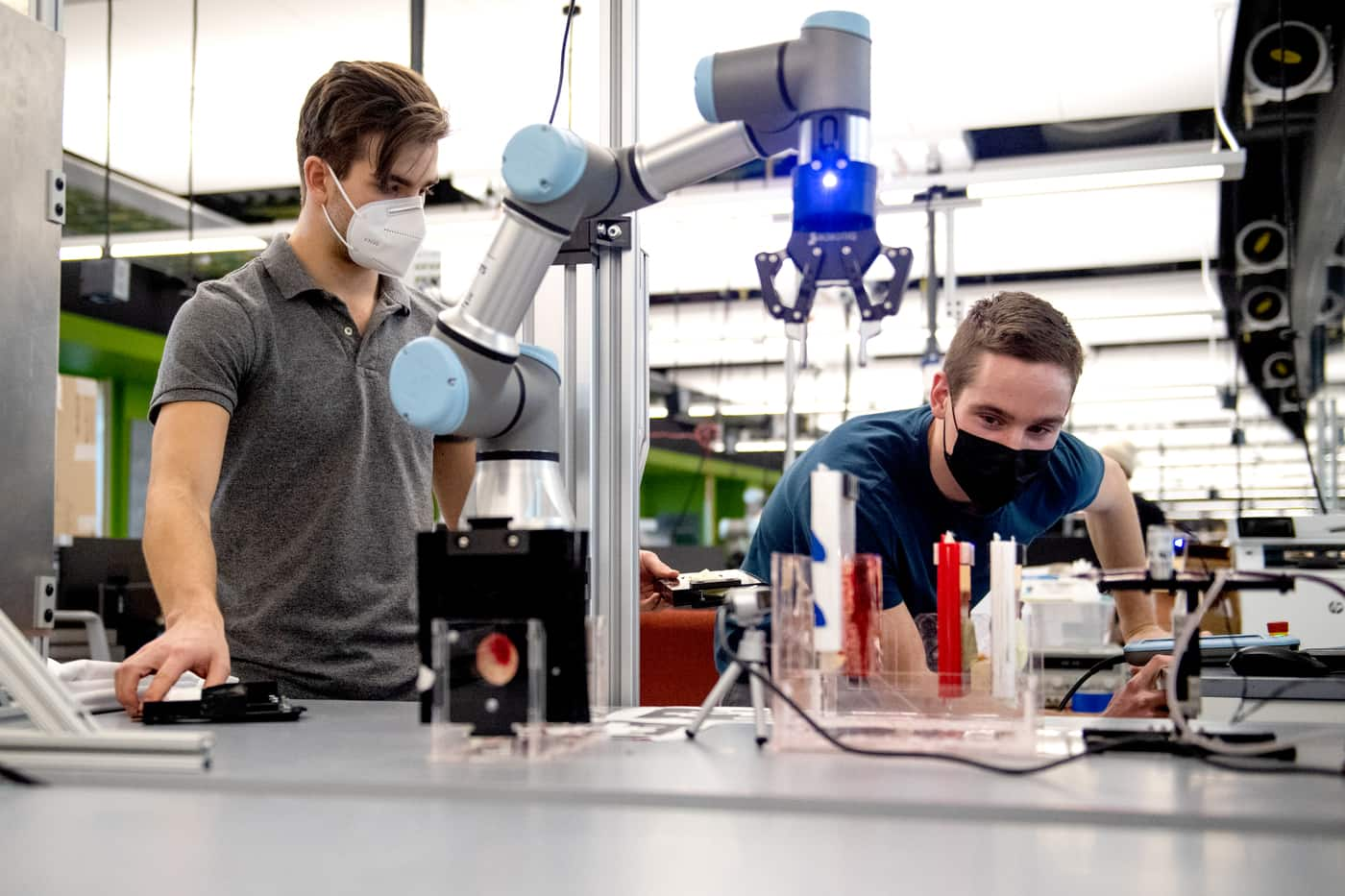

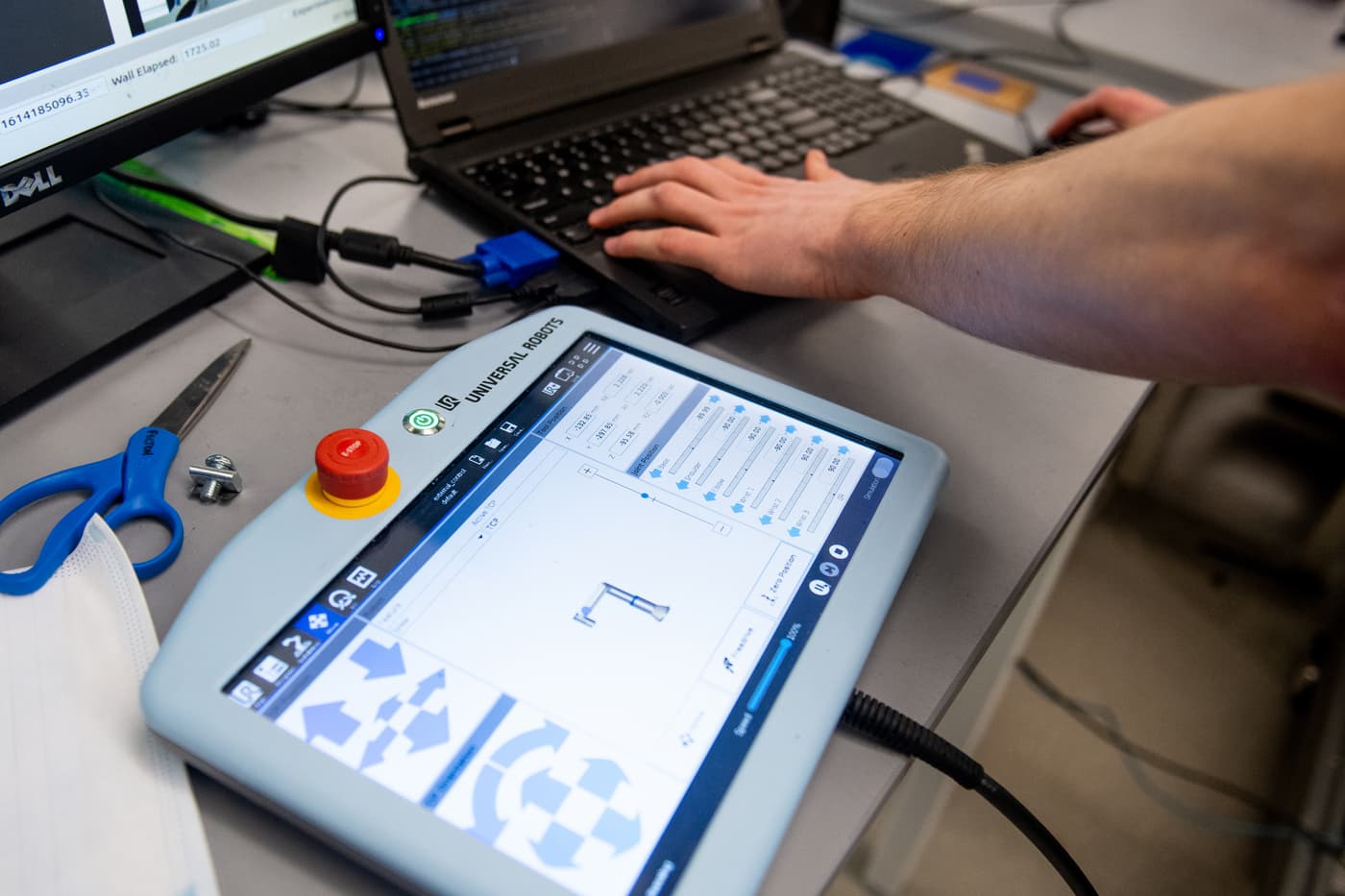

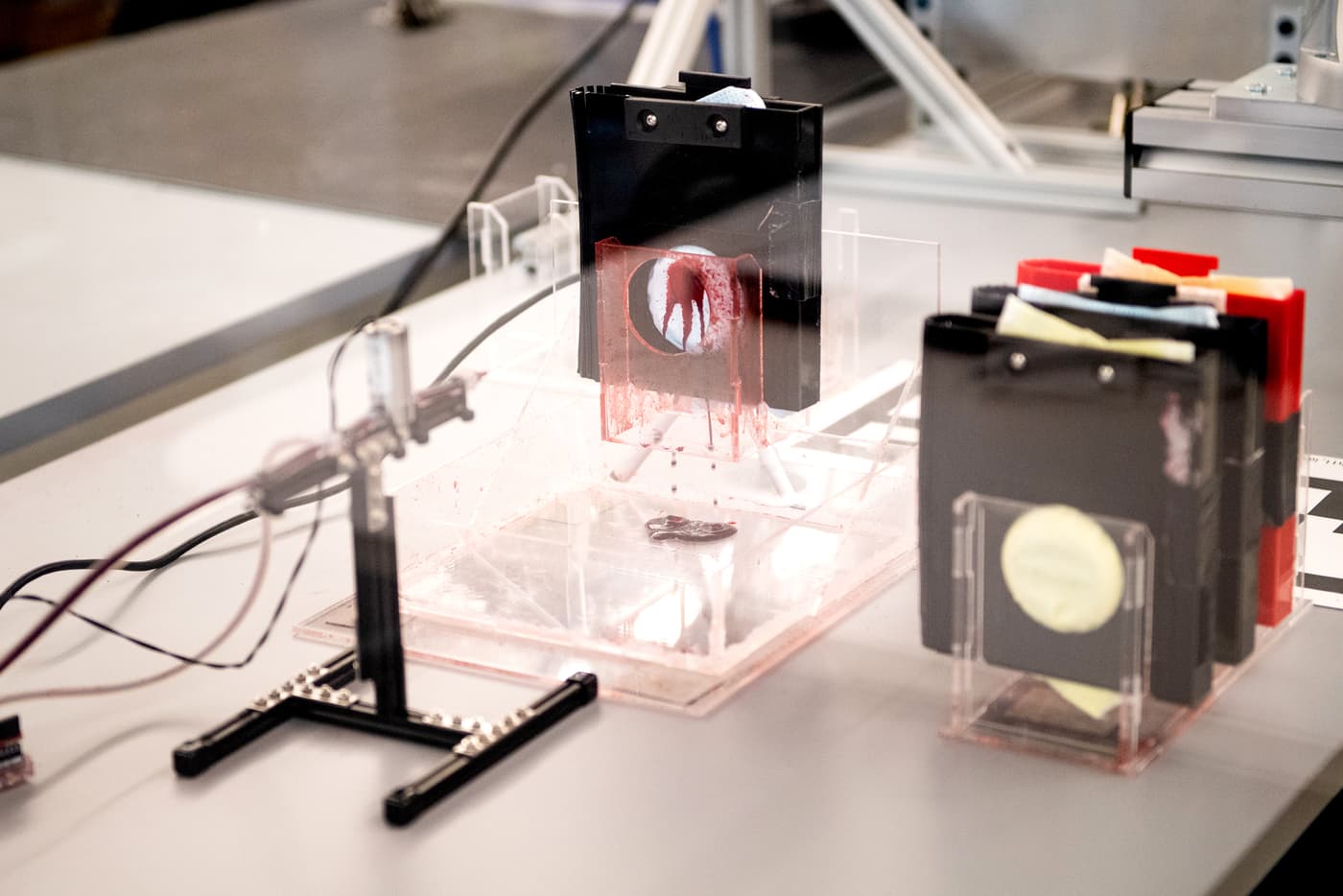

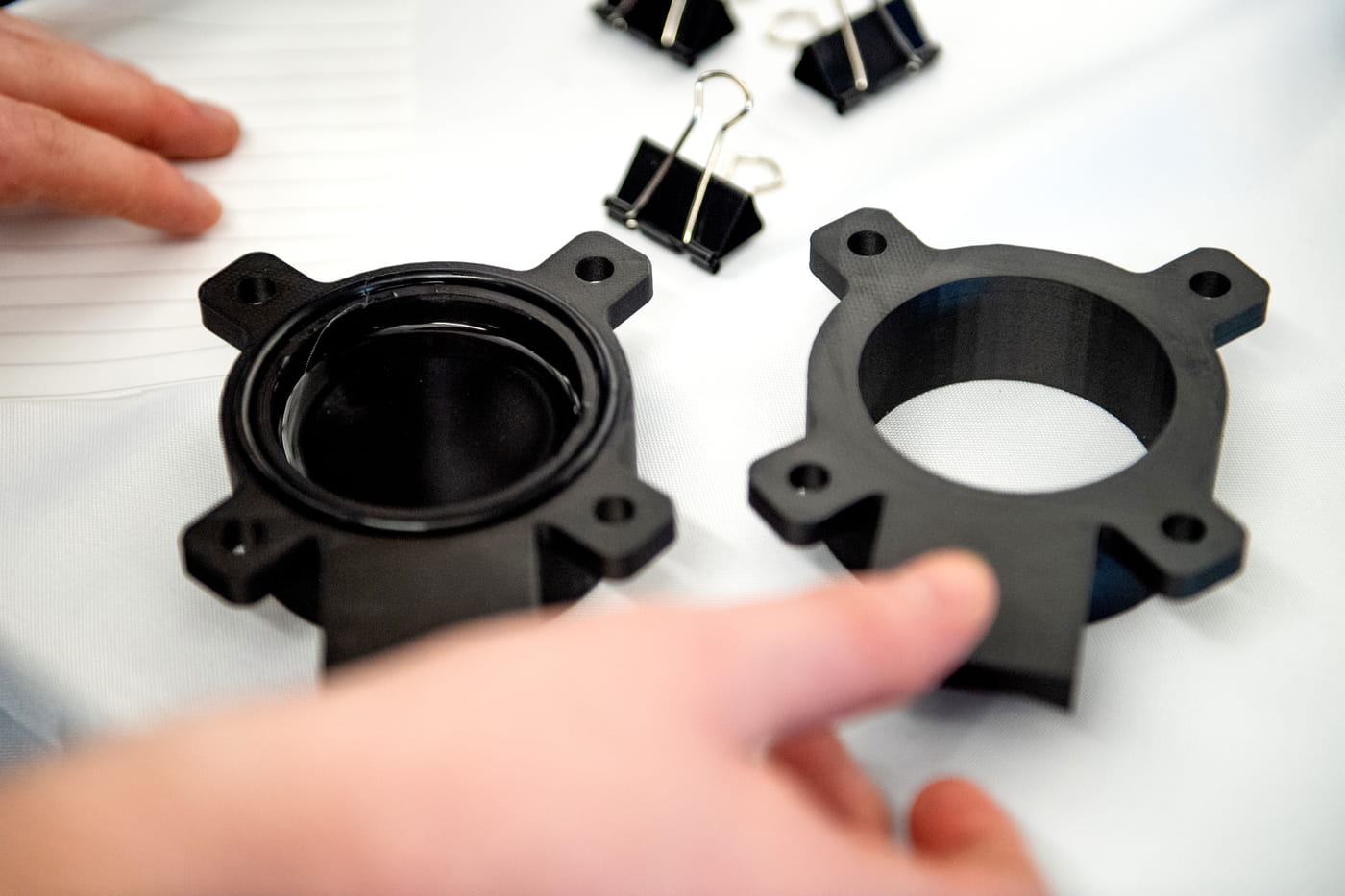

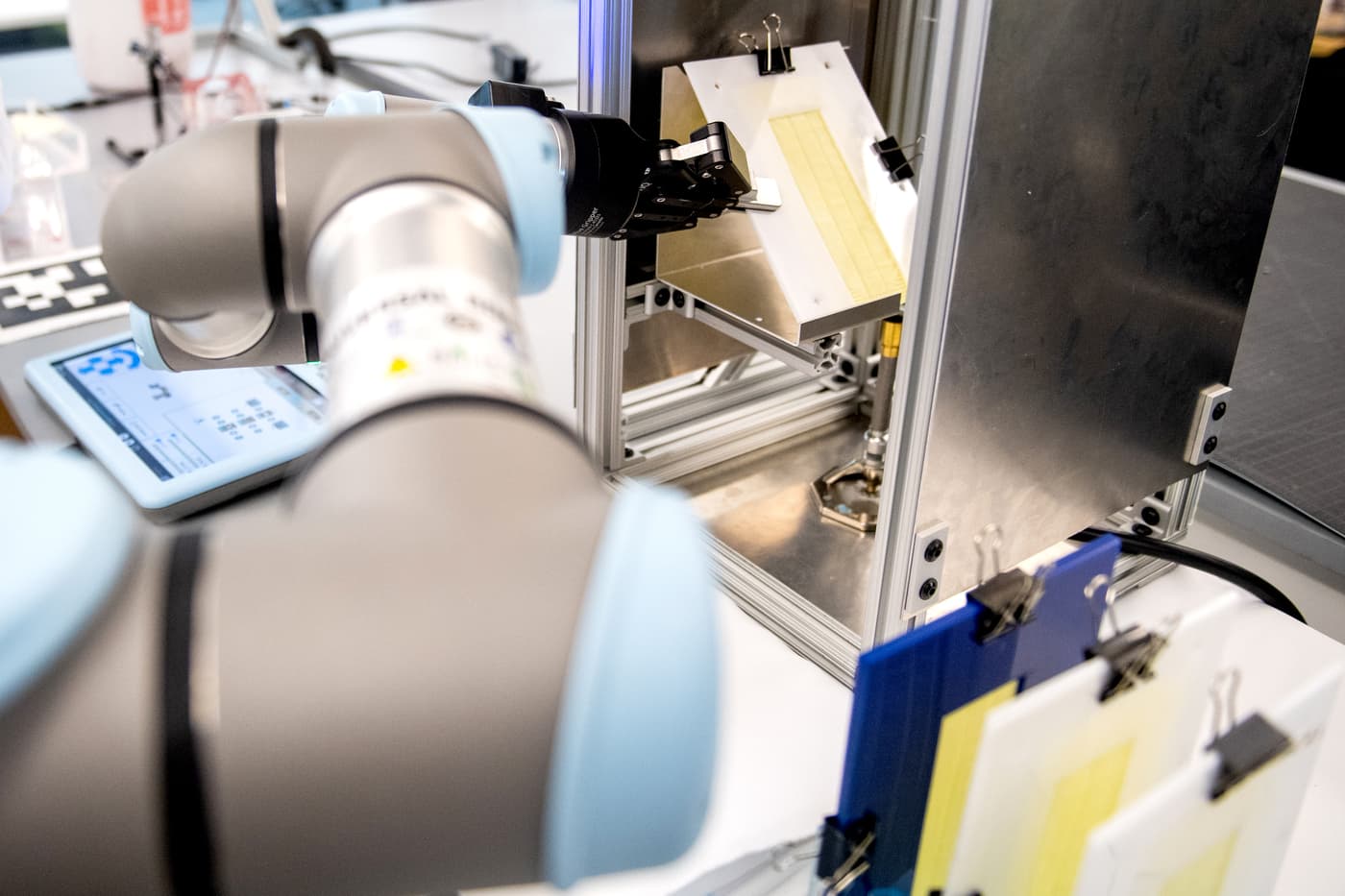

This project sought to automate the quality assurance tests for inspection in PPE manufacturing, thus improving the performance, productivity, and efficiency of Personal Protective Equipment (PPE) manufacturing in the U.S. by streamlining the process of automated characterization and evaluation.

Automated Characterization in PPE Manufacturing Project Technical Approach

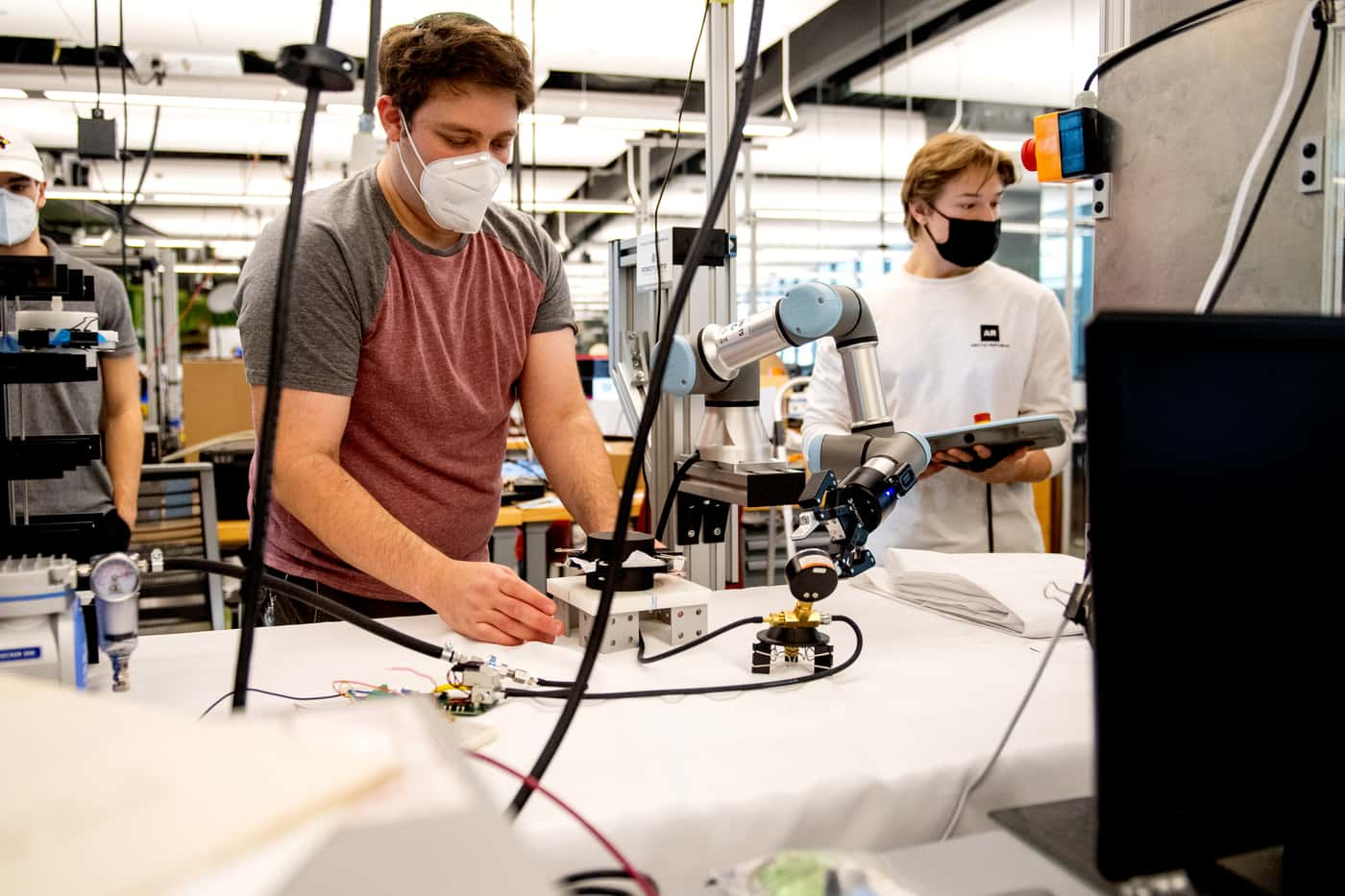

The quality assurance procedures for Personal Protective Equipment (PPE), such as facemasks, is labor intensive and time consuming. Sample testing of PPE has become a priority not only in manufacturing plants but also at medical centers. The national labs providing validation testing for PPE are reporting lead times up to 75 days due to lack of qualified technicians and the overwhelming volume of new requests. This project aims to develop a robotic system to automate characterization and evaluation in PPE inspection, thus improving the performance, productivity, and efficiency of PPE manufacturing in the United States.

Automated Characterization in PPE Manufacturing Project Impact

This project created technology that enables the rapid expansion of a USA industrial base in the category of AAMI tested medical PPE manufacturing. The project also resulted in the ability to perform three separate quality assurance tests in-house by integrating robotics and automation into the quality assurance processes for PPE manufactured in the US. This will help to addresses supply chain variability issues.

The technology could also be used for fluid penetration tests, flammability tests, liquid barrier tests, and similar QA tests. It also has applications in laboratory automation, medical device manufacturing, biopharmaceutical, and furniture and garment manufacturing.

Automated Characterization in PPE Manufacturing Project Participants

Principal Investigator: Northeastern University

Project Team: Merrow Manufacturing