Background

Finishing tasks are among the most challenging manufacturing operations from ergonomic considerations; they are often performed in dusty conditions with human workers in uncomfortable positions. This defect correction automation project creates an end-to-end finishing solution using a robot-based scanning and inspection system to identify imperfections and robot-based manufacturing defects correction. Automating the manufacturing finishing process will lead to reduction in time spent and overall operations costs.

Objective

Automate finishing tasks, focusing specifically on deburring finishing operations, to decrease cost and increase safety for human workers by minimizing ergonomically unfriendly tasks via manufacturing robots.

Technical Approach

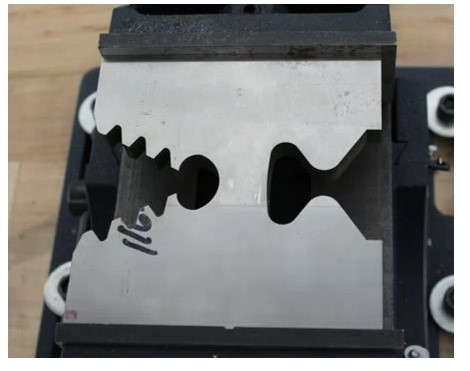

This project focused specifically on deburring finishing. The main challenge in deburring finishing operations is finding a way to automatically define the trajectory and other deburring parameters for a part that may have defects at several locations. This project addresses this challenge through an approach using robotic deburring that:

- Scans selective regions of a part with expected defects, identifying defects that exceed accepted tolerances and must be corrected

- Automatically generates robot paths and other proposed parameters, driving a robot with a deburring tool end effector along the generated path to correct defects

Participants

Siemens (Principal Investigator), CCAM, Yaskawa, Arconic