This Project was selected from the ARM Institute’s 23-01 Technology Project Call that addressed the following topic areas:

- Automated Robotic Task Planning

- Multi-Robot, Multi-Human Collaboration, Task Sharing & Task Allocation

- Safe and Scalable Manufacturing of Energetics

- Artificial Intelligence (AI) in Robotics for Manufacturing

- Discovery Workshops and Market Studies

Project Team:

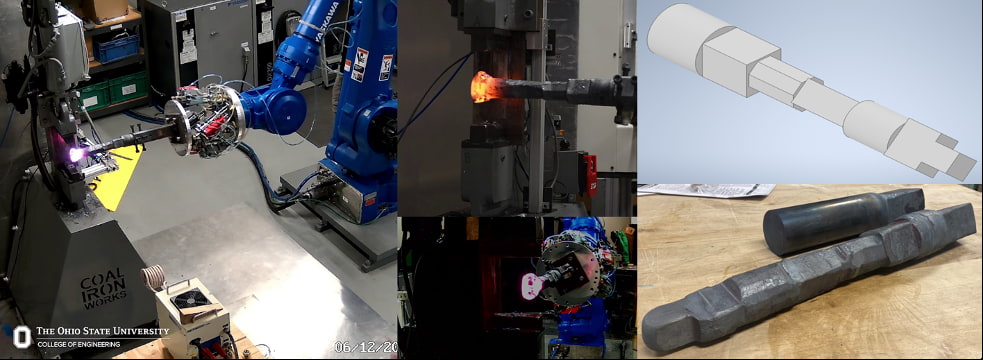

Ohio State University (Principal Investigator), CapSen Robotics, Yaskawa, and Warner Robbins Air Force Base

Topic Areas Addressed:

Artificial Intelligence (AI) in Robotics for Manufacturing

Description:

This project builds on the outputs from the previously funded ARM Institute Autonomous Robotic Metal Forming project. There is a growing need for small volume, high mix manufacturing, such as in cases of manufacturing replacement components for aging systems or personalized medical implants. However, there is a limited supply chain for one-off components, and complex components require expensive machining and/or tooling and dies. This robotics forging project seeks to drastically accelerate the productivity of the robotic system created in phase one of this project by:

- reducing the time required to position the component on the lower die

- removing the need for pauses during pressing to relieve forces and torques

- allowing for larger amounts of deformation to be taken on each iteration

- reducing the number of images needed for component geometry reconstruction

- reducing the time to heat material to forging temperatures

- reducing the amount of deformation needed to transform the initial geometry to the final geometry

- reducing the frequency of component imaging.