Background for Robotic Clothing Manufacturing

Most apparel manufacturing is done abroad, which leads to lengthy supply chains. This supply chain issue poses a significant risk, as seen when the U.S. struggled to scale up production of PPE. This project team will leverage results from a previously funded ARM project to expand upon it by delivering a modular work-cell that can be configured to perform end to end automated assembly of PPE, such as isolation gowns, with the end-goal of easily replicable robotic clothing manufacturing

.

Objective of Robotic Clothing Manufacturing

Spur automated solutions in robotic sewing, specifically to more quickly and safely manufacture personal protective equipment (PPE).

Technical Approach to Robotic Clothing Manufacturing

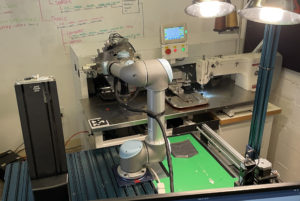

By building on the advancements and outputs of previously funded ARM Institute projects, the Bot Couture project advanced the state of the art in robotic sewing and demonstrated the feasibility of the technology in a representative environment at the Levi Strauss Innovation Center. Through the project, the team developed a robotic system which can be used to perform machine tending operation in the apparel sector and a closed loop visual servoing technique to perform precise sewing. The team also developed modular software components that can be reused in this and other industrial robotics applications.

Impact of Robotic Clothing Manufacturing for the DoD

The Department of Defense (DoD) buys an extraordinary amount of sewn goods – from uniforms, to tents, to parachutes, and more. By using robotic clothing manufacturing to produce these inexpensively in the US, we will secure our supply chain and reduce costs. Commercial companies like Levi’s, DoD suppliers like Bluewater Defense, and sewing machine technology providers like Henderson Sewing Machine Company are seeking to integrate this capability into their processes and products. These ARM Institute projects are directly complimentary to the work undertaken by AFFOA and Drexel’s Center for Functional Fabrics.

Participants

Siemens Technology (PI) Partners: Sewbo, Henderson Sewing, ISAIC, Bluewater Defense