Customized Mask Assembly Project Background

In spring 2020, the ARM Institute issued a special COVID-19 focused project call in partnership with the U.S. Department of Defense. This robotics project was funded from that call for proposals.

The ARM Institute rapidly responded to the Department of Defense’s need to address COVID-19 by forming numerous national teams, drawing from diverse industries and technologies to address the myriad of supply chain shortages. This is highlighted by a few of the key statistics listed below:

- Rapid contracting with 45 days from the Project Call release to project start

- Projects executed in 12 months

- 13 states and Puerto Rico engaged

- 23 unique organizations participated across the nine projects

Customized Mask Assembly Project Objective

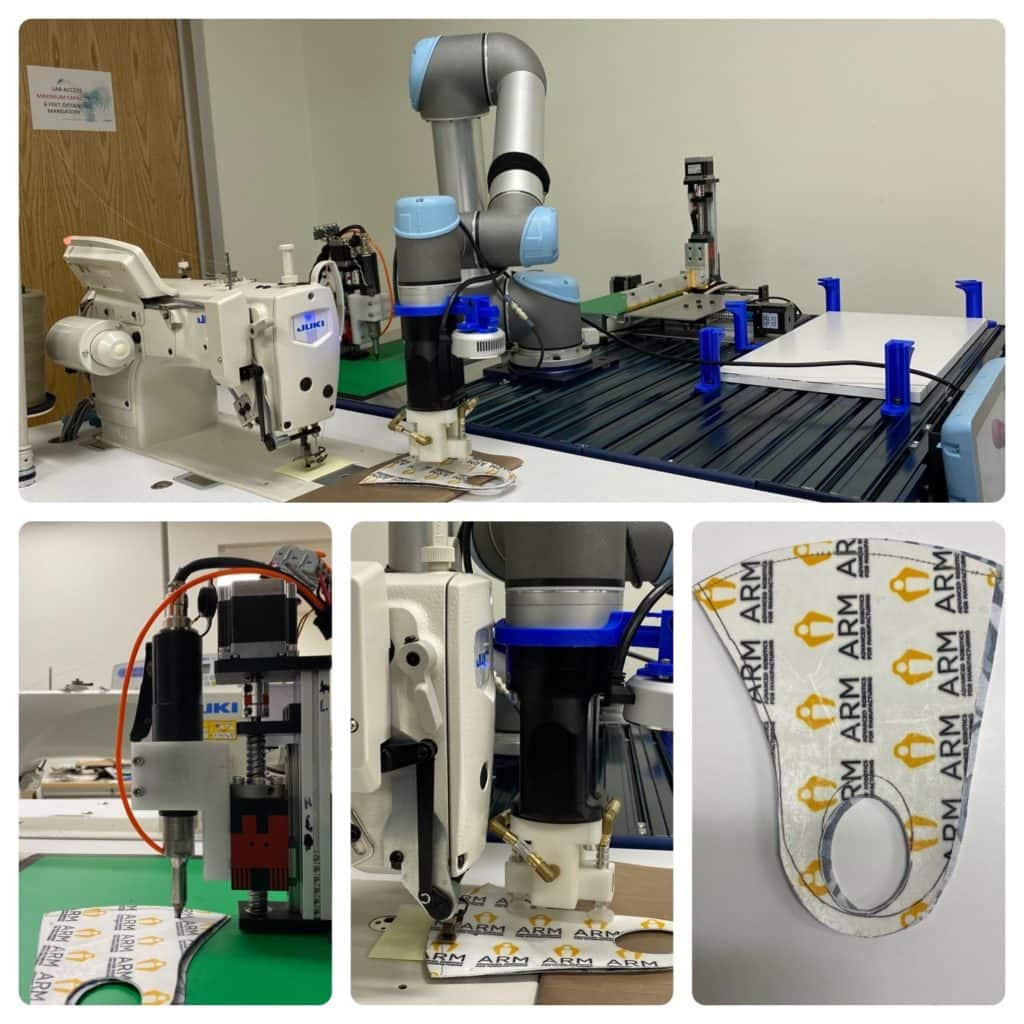

This project automated the production of cloth masks by building off of the outputs from previous ARM Institute funded robotics projects.

Customized Mask Assembly Project Technical Approach

The Center for Disease Control (CDC) has identified cloth masks as playing a vital role in slowing the spread of COVID-19, but the supply of these cloth masks has not been able to keep up with the demand. Robotic sewing presents a technical challenge because it requires the manipulation of flexible materials, fine motor control, and precise part recognition. This project built upon the outputs from other ARM projects to automate customized mask assembly via robotics for personal protective equipment (PPE).

Customized Mask Assembly Project Impact

This project enables customized mask assembly anytime, anywhere. It also increased the use of automation in an industry that continues to rely primarily on manual labor, helping to boost efficiency and production speed in the production of PPE.

Customized Mask Assembly Project Participants

Principal Investigator: Siemens Corporation Corporate Technologies

Project Team: Henderson Sewing Machine Corporation, Sewbo Inc, Bluewater Defense, Industrial Sewing and Innovation Center (ISAIC)