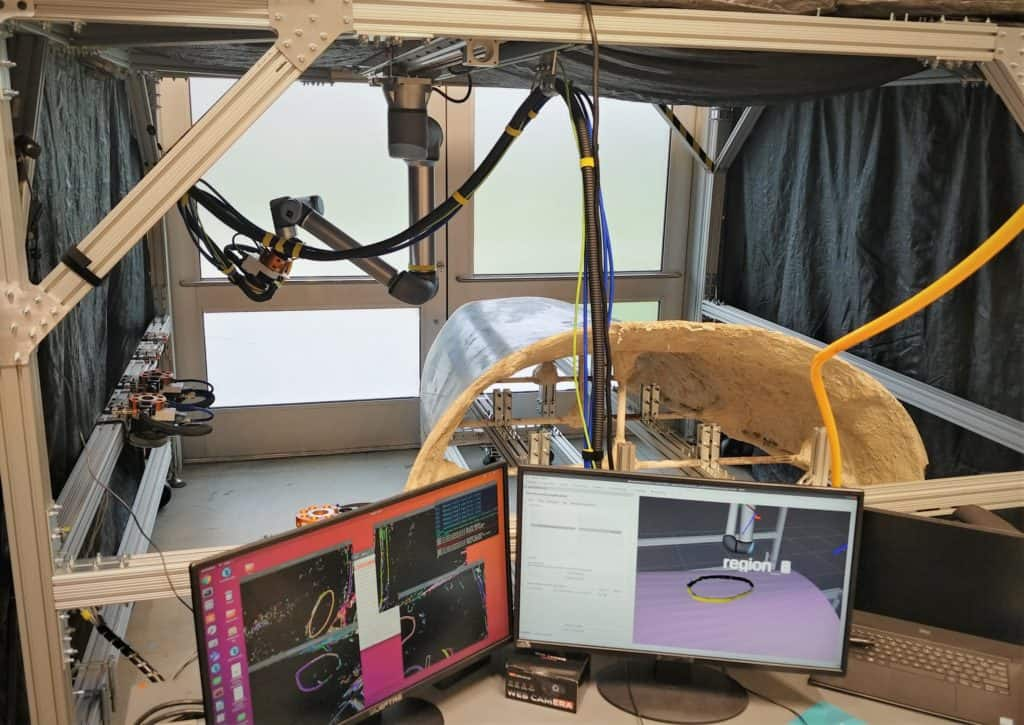

Robotic Sanding Project Background

This robotics project developed a collaborative robotics system to aid skilled workers in sanding composite aircraft panels. Automating this process reduces worker exposure to hazardous conditions. Additionally, this project resulted in increased product quality and will reduce labor hours per unit. This reduction in automation costs will allow the project to be used by both large and small manufacturers. The planned output of this project will empower American workers to compete with low-wage workers abroad by multiplying the productivity and yield of the American worker, with sanding robots being the catalyst for this increase in productivity.

Robotic Sanding Project Objective

Development of a cost-effective, human-safe robotic cell that allows human workers to perform concurrent tasks alongside the robot, maintaining the existing factory layout, and allowing manufacturers to implement this technology without the need for drastic shifts in factory floor planning.

Robotic Sanding Project Technical Approach

The high-cost and disruption to the manufacturing process have prevented the deployment of automated sanding technologies on most aerospace applications. This project addresses these concerns through the development of a collaborative, human-safe robotic cell that can fit into the existing factory floor plans.

Robotic Sanding Project Participants

Spirit AeroSystems (Principal Investigator), Southwest Research Institute, Wichita State University