Project

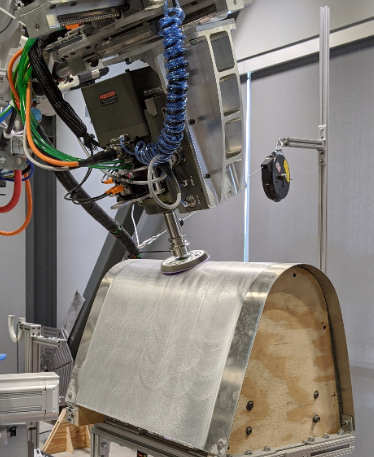

This project advanced the technology used to sand large metallic panels that are often round and cylindrical in shape. This project includes designing and implementing a robot end effector and utilizing vision-based machine learning to identify areas that require sanding. The end product resulted in increased productivity; a single worker can now supervise the sanding of several panels simultaneously. Similarly, this reduces the technical and operational barriers to adopting robotic technologies by providing the cell layout, end effector designs, and code to automate a complete sanding cell.

Objective

Advance the technology used to sand large metallic panels, resulting in a singular worker being able to adequately supervise the sanding of several panels simultaneously.

Technical Approach

The CDIP from this project include increased safety for human-robot interaction and flexible and adaptive metallic sanding. The project will center on the following developments:

- Development of a tunable random orbit and integrate with a robot

- Force sensor and other sensor integration for path adjustments

- Surface finish inspection and system integration

- Cell design and risk assessment

This project includes designing and implementing a robot end effector and utilizing vision-based machine learning to identify areas that require sanding.

Participants

Wichita State University (Principal Investigator), GKN Aerospace, University of Connecticut