Background

The Composite market in US is currently $26.7 billion and the annual growth rate is 3.8%, but progress is inhibited by current manual processes.

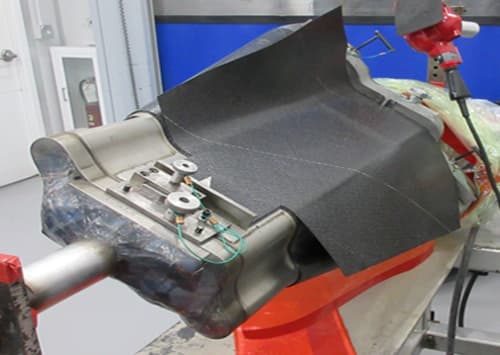

Current composite layup processes are manual, costly, time-consuming, and suffer from inconsistencies. This project team is working to develop a hybrid cell that will facilitate better human-robotic collaboration in the composite layup process. This is expected to reduce touch labor during the layup process, reduce debulking steps, and increase throughput.

Objective

Current processes rely on manual labor; this project seeks to catalyze a solution that will lower costs, reduce the amount of manual labor needed, and reduce the time spent.

Technical Approach

The team will focus on advances in perception, planning, and control to enable robotic cells in the composite layup process. This project demonstrates technical feasibility of automating composite layup process on a complex rotating tool using a hybrid cell. The team also incorporated sensing, planning and execution monitoring technologies to automatically generate robot instructions for cell operation on a complex rotating tool

Participants

Lead: University of Southern California Partners: Lockheed Martin, Southwest Research Institute