Background

This project was funded through the ARM Institute’s COVID-19 focused Project Call held in partnership with the U.S. Department of Defense.

The ARM Institute rapidly responded to the Department of Defense’s need to address COVID-19 by forming numerous national teams, drawing from diverse industries and technologies to address the myriad of supply chain shortages. This is highlighted by a few of the key statistics listed below:

- Rapid contracting with 45 days from the Project Call release to project start

- Projects executed in 12 months

- 13 states and Puerto Rico engaged

- 23 unique organizations participated across the nine projects

Objective

Copper-coated surfaces have the ability to kill the coronaviruses like COVID-19 and others. This project seeks to enable the robotic cold spraying of copper to allow wider adoption of copper surfaces.

Technical Approach

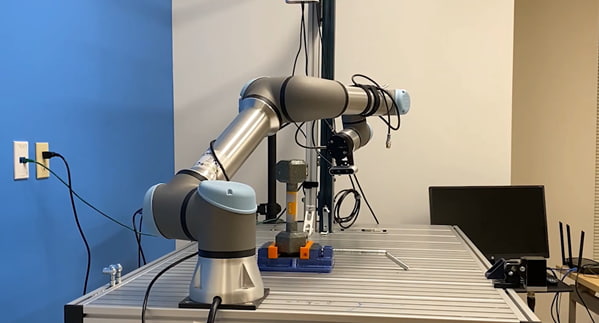

Copper-coated surfaces rapidly kill coronaviruses like COVID-19, but these have not been widely manufactured due to low demand. However, the pandemic has highlighted the need for self-disinfecting surfaces. Robotic cold spraying of copper will enable rapid production to meet the new demand. Wide adoption of copper-coated surfaces will reduce the spread of COVID-19 without the need for frequent cleaning. The robotic application of copper coating will improve the manufacturability of these parts. This project will develop a robotic anti-microbial copper application system (cold spray), integrating a scanner and developing an automated path generation and QA tools to apply the copper coating to components like a doorknob, hospital bench, cart, handrail, etc.

Impact

The project resulted in a production ready semi-automated Robotic cold spray to provide self-disinfecting high touch items. The set-up is ready to be used “as a tested” system (VRC Metal Systems spray, NX CAM Robotics, Sinumeric Controler, Comau Robot with RunMyRobot.). The set-up is also easily customizable. The project also advanced the technology closet to an easy-to-use stand-alone system for the scanning and spraying of miscellaneous parts.

The robotic application of cold spray also has many other applications in repair, additive manufacturing, and more. The system could be adapted to mobile robots for scanning and coating of fixed assets, large objects.

Participants

Principal Investigator: Siemens Corporation Corporate Technologies

Project Team: VRC Metals Systems