Background

Background

The Department of Commerce’s National Institute of Standards and Technology (NIST), through the CARES Act, provided funding to the ARM Institute to collaborate with Wilder Systems to develop this technology. The ARM Institute put out a call to our members for solutions to mitigate the COVID-19 pandemic. This robotics project resulted from that call for proposals.

Project

This robotic COVID-19 system can be deployed at any lab and can continuously run test samples with minimal human involvement. A typical small lab can run about three cycles a day of 94 samples per an eight-hour shift, or 280 tests per day. The Wilder system can run continuously for 24 hours with minimal technician supervision and run up to 2,000 samples per day with the same number of staff and PCR equipment resulting in a 7x increase. Tests performed with the WS system in Austin guarantee results to patients within 24 hours, further augmenting the country’s supply of rapid test results.

Objective

Increase the availability and speed of COVID-19 testing while keeping humans safe.

Technical Approach

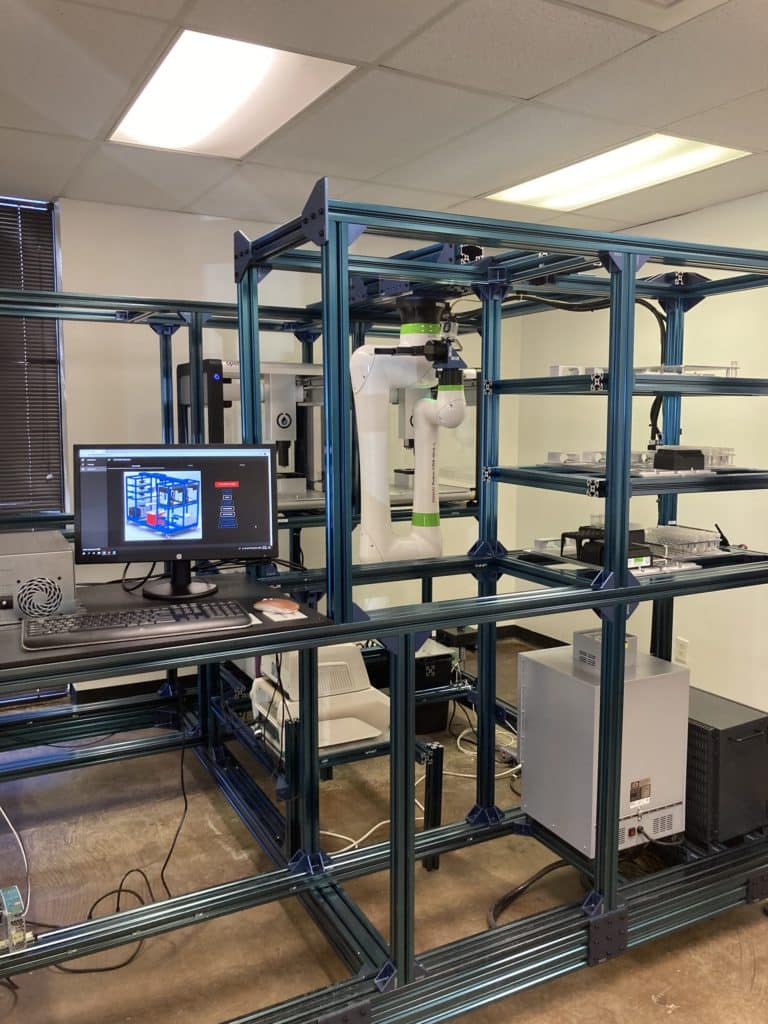

The project team led by ARM Institute member Wilder Systems built a robotic test cell that contains a 7-axis robotic arm, robotic liquid handlers for collection tube plating, polymerase chain reaction (PCR) testing prep, the RT-qPCR analyzer itself, a hazardous waste bin, and control software. A technician starts the testing process by supplying the sample in a test tube, the robotic system then processes it, and the results are quickly delivered.

Impact

The entire system can be deployed at any lab and has demonstrated its ability to continuously run test samples with minimal human involvement. A typical small lab can run about three cycles a day of 94 samples per an eight-hour shift, or 280 tests per day. The Wilder system can run continuously for 24 hours with minimal technician supervision and run up to 2,000 samples per day with the same number of staff and PCR equipment resulting in a 7x increase. Tests performed with the WS system in Austin guarantee results to patients within 24 hours, further augmenting the country’s supply of rapid test results.

Participants

Wilder Systems