Featured Impact: From Manufacturing Challenge to Robotics Solution in 6 Weeks

Problem Statement

Penna Flame, a third-generation a family-owned and operated manufacturer that performs flame and induction hardening of cast parts, wanted to find a way to automate their packaging process both to save cost and improve the safety of their employees, as each part weighs 30+ pounds each. Penna Flame already had a robot in their facility that was not being utilized to its fullest extent and wanted to modify its use for packaging. The size of the parts, the part shape, the limitations of their current robot, and the need to robotic coat parts with oil without impeding robot vision sensors created challenges to automating this process, creating the need for a custom robotics solution to address these pain points.

Our Process & Solution

The ARM Institute’s Robotics Manufacturing Hub team completed market research and tested robotic end effectors that could withstand oil exposure, successfully maneuver the parts, and fit the static and dynamic load capacity of the existing robot. Ultimately, the Robotics Manufacturing Hub team selected an off-the-shelf air controlled magnetic end effector and modified it slightly to meet the manufacturer’s requirements. The Robotics Manufacturing Hub team also completed an engineering analysis to identify successful part pick up techniques and safe operating parameters for Penna Flame’s existing robot. The team then completed a proof-of-concept of a robotic oil dipping process vs spray gun application to make the process a better fit for optimal robotic performance, customizing the robotic solution for Penna Flame’s specific needs.

This engineering solution (program code, bill of material, and calculations) was handed off to CapSen Robotics, a local ARM Institute Member company, so that the solution could be combined with CapSen’s AI software for automated picking and placing.

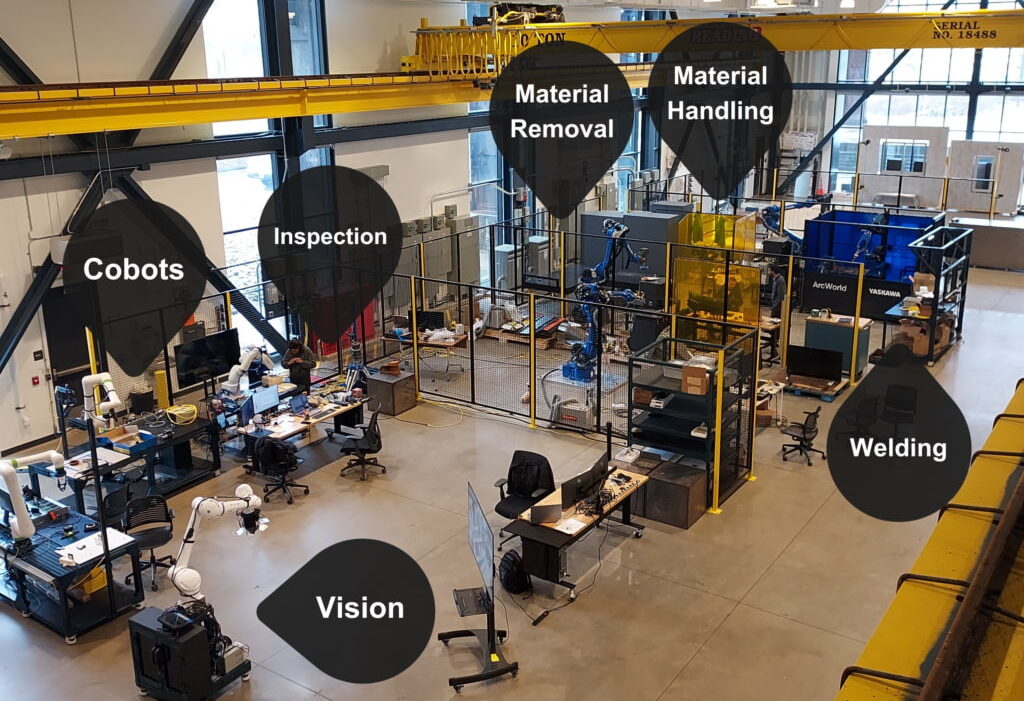

The robotics solution was successfully tested and demonstrated the ARM Institute’s Robotics Manufacturing Hub facility in Pittsburgh’s Hazelwood neighborhood. Penna Flame has now integrated the solution into their facility, enhancing their competitiveness and improving working conditions for their team.

By doing a proof-of-concept, this manufacturer was able to identify an issue with their current robot’s capabilities that would have significantly degraded expected performance and obtain a proven solution before ever purchasing equipment or software. By leveraging this custom robotics solution, Penna Flame saved time, money, and effort that may have been wasted should this proof-of-concept not have come to fruition.