2023 marked yet another year of historic growth for the ARM Institute! From launching new robotics and workforce capabilities to growing our consortium of experts, take a look back at just a few of our favorite moments from 2023 below.

This impact would not be possible without our members, government partners, council and committee members, board of directors, and internal team of experts. Thank you for your continued support and all that you do with the ARM Institute to strengthen U.S. manufacturing and secure a brighter future for the U.S. workforce.

Engagement with National Leadership

The ARM Institute’s work continued to generate attention from national leaders. This visibility translates into opportunities for our members and partners. We hosted and participated in a number of high profile visits and events.

Visits by the First Lady of the U.S. and Pittsburgh’s Designation as a National Workforce Hub

Pittsburgh, home to the ARM Institute’s headquarters, was named one of five national Workforce Hubs where President Biden’s Investing in America agenda—including the American Rescue Plan, Bipartisan Infrastructure Law, CHIPS and Science Act, and Inflation Reduction Act—are catalyzing private and public investments and creating good-paying jobs. Through this initiative, the ARM Institute interfaced with leaders that included Dr. Jill Biden (First Lady of the United States), Julie Su (U.S. Acting Secretary of Labor), and Pete Buttigieg (Transportation Secretary of the U.S.).

Pittsburgh, home to the ARM Institute’s headquarters, was named one of five national Workforce Hubs where President Biden’s Investing in America agenda—including the American Rescue Plan, Bipartisan Infrastructure Law, CHIPS and Science Act, and Inflation Reduction Act—are catalyzing private and public investments and creating good-paying jobs. Through this initiative, the ARM Institute interfaced with leaders that included Dr. Jill Biden (First Lady of the United States), Julie Su (U.S. Acting Secretary of Labor), and Pete Buttigieg (Transportation Secretary of the U.S.).

Dr. Jill Biden visited Pittsburgh twice for this effort, once at the ARM Institute’s Mill 19 headquarters in Pittsburgh’s Hazelwood neighborhood. During this visit, ARM Institute robotics demonstrations were on display, including our Robotics Manufacturing Hub capabilities. Through the Pittsburgh Workforce Hub, the ARM Institute is working with ARM Member New Century Careers on an initiative that will provide new, rapid, short-term, employer-driven training to help dislocated workers re-enter the workforce in good quality, high-demand manufacturing jobs using robotics. The ARM Institute will also leverage a new grant from the Department of Defense’s Manufacturing Technology Program to expose more school-age children in the Pittsburgh region to manufacturing careers, by funding local nonprofit STEM Coding Lab to deliver robotics education to Pittsburgh-area Title I schools and expanding Manufacturing Day programs into rural areas.

The ARM Institute is honored to support this initiative and is excited for progress to continue to accelerate in 2024.

Input into White House Strategy

Our collaboration with the White House extends beyond Pittsburgh. Ira Moskowitz, ARM Institute CEO, represented the ARM Institute alongside our fellow Manufacturing USA Institutes at the Advanced Manufacturing Workforce Sprint on National Manufacturing Day at the White House. This nationwide sprint brings together employers, unions, education and training providers, community-based groups, philanthropic organizations, and state and local governments to take concrete steps to help more Americans train for jobs in advanced manufacturing.

Our collaboration with the White House extends beyond Pittsburgh. Ira Moskowitz, ARM Institute CEO, represented the ARM Institute alongside our fellow Manufacturing USA Institutes at the Advanced Manufacturing Workforce Sprint on National Manufacturing Day at the White House. This nationwide sprint brings together employers, unions, education and training providers, community-based groups, philanthropic organizations, and state and local governments to take concrete steps to help more Americans train for jobs in advanced manufacturing.

In May, Ira was one of just a few experts invited to participate in a White House discussion on the impacts of artificial intelligence (AI) on manufacturing alongside ARM Member Satyandra Gupta (USC & GrayMatter Robotics). The conversation centered on the impact of AI on the manufacturing workforce, how AI can improve manufacturing processes, and what government support is needed to navigate the changes created through greater AI integration.

Manufacturing USA Workforce Strategy Meeting at Mill 19

The ARM Institute continued to act as a critical convener for the nation. One example of this was the Manufacturing USA Workforce Strategy Meeting hosted at our Pittsburgh facility in March. This meeting convened representatives from the Manufacturing USA Institutes, the Department of Defense, The White House, U.S. Department of Labor, U.S. Department of Education, U.S. Department of Commerce, National Institute of Standards and Technology (NIST), and other key stakeholders to explore cross-institute workforce strategies, existing institute efforts, and strategies moving forward to empower the U.S. manufacturing workforce. The outputs from this meeting, and others in this series, will be used to inform White House workforce policy.

Point of Need Challenge supporting the Department of Defense

In partnership with the Office of the Secretary of Defense Manufacturing Technology (OSD ManTech) and the ARM Institute’s fellow Manufacturing Innovation Institutes (MIIs), the ARM Institute hosted an event at our facility in Pittsburgh centered on Point of Need Manufacturing Challenges. This event included an OSD-led Requirements Workshop and pitch presentations from MII project teams that were selected from the associated MII Point of Need Manufacturing Challenge Project Call.

This meeting convened key stakeholders from OSD, including BG David Trybula of Army DEVCOM and Dr. Karl Dahlhauser of OUSD(R&E) Science & Technology Futures, and representatives from the Joint Staff, the Services, and Defense Agencies. From the workshop and associated project call, the ARM Institute Corsha project was selected for funding.

Engagement with Ms. Heidi Shyu, the Under Secretary of Defense for Research and Engineering (OUSD(R&E))

We joined our fellow Manufacturing Innovation Institutes part of the Manufacturing USA Network at the Defense Manufacturing Conference (DMC) in December. During DMC, Ms. Heidi Shyu, the Under Secretary of Defense for Research and Engineering (OUSD(R&E)) learned about several ARM Institute projects by visiting our booth and member booths.

Her first visit was to the ARM Institute booth where we demonstrated a mixed reality solution for sustainment and maintenance provided by ARM member GridRaster. Ms Shyu then visited the booth of ARM Member Corsha where she learned about a Defense Point-of-Need project for manufacturing and cybersecurity solutions at the austere edge in frostbite weather. She then visited ARM member ARIS Technology where she learned about an ARM Institute funded project integrating mixed reality with robotic simulation for inspection and asset defects mapping.

Awards

The ARM Institute and our internal team again won a number of high profile awards in 2023:

- Livia Rice, ARM Institute Senior Outreach Manager, was named one of the top 30 professionals under the age of 30 by the Pittsburgh Business Times

- Ira Moskowitz, ARM Institute CEO, received an Ecosystem Advocate Award through the Fire Awards by Pittsburgh Inno

- Ira Moskowitz was a finalist for the CEO of the Year Award through the Pittsburgh Technology Council’s Tech50 Awards and the ARM Institute itself was named a Pittsburgh Tech Council Tech50 finalist

- Tasha Miller, ARM Institute Program Manager, was featured in the Pittsburgh Business Times’ list of 20 people to know in manufacturing

- The ARM Institute was again named one of the Best Places to Work by the Pittsburgh Business Times

Ecosystem Highlights

2023 marked a historic year of growth for the ARM Institute as our consortium grew to more than 400 member organizations. Organizations in our consortium include start-ups, community colleges, universities, non-profits, manufacturers of all sizes, defense suppliers, robotics manufacturers, and others. Within these 400+ organizations are thousands of subject matter expert collaborators working to strengthen the advanced manufacturing capabilities of U.S. manufacturers through collaboration.

With such a large and active consortium, it’s important to recognize our members who go above and beyond to advocate for our mission and strengthen U.S. manufacturing. We recognize these members annually at our Member Meeting with ARM Champion awards. Our 2023 class of ARM Champions celebrated:

- Corey Adams (Universal Robots)

- Maria Araujo (Johnson & Johnson)

- Clint Chapman (Yaskawa)

- SK Gupta (USC/GrayMatter)

- Mingu Kang (ARIS Technology)

- Jeannine Kunz (SME)

- Changliu Liu (CMU)

- Dan Mantz (REC Foundation)

- Tom Mudano (AmSkills)

- Ritch Ramey (A3 – Association for Advancing Automation)

- Curtis Richardson (Spirit AeroSystems)

- Eugen Solowjow (Siemens)

Technology Highlights

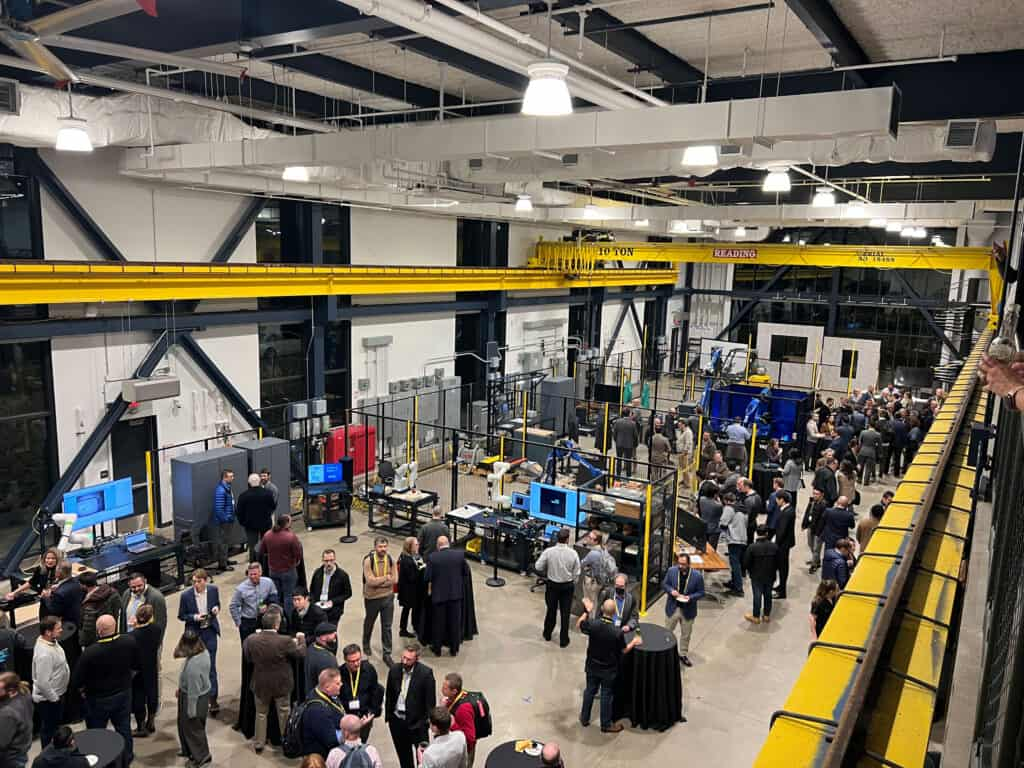

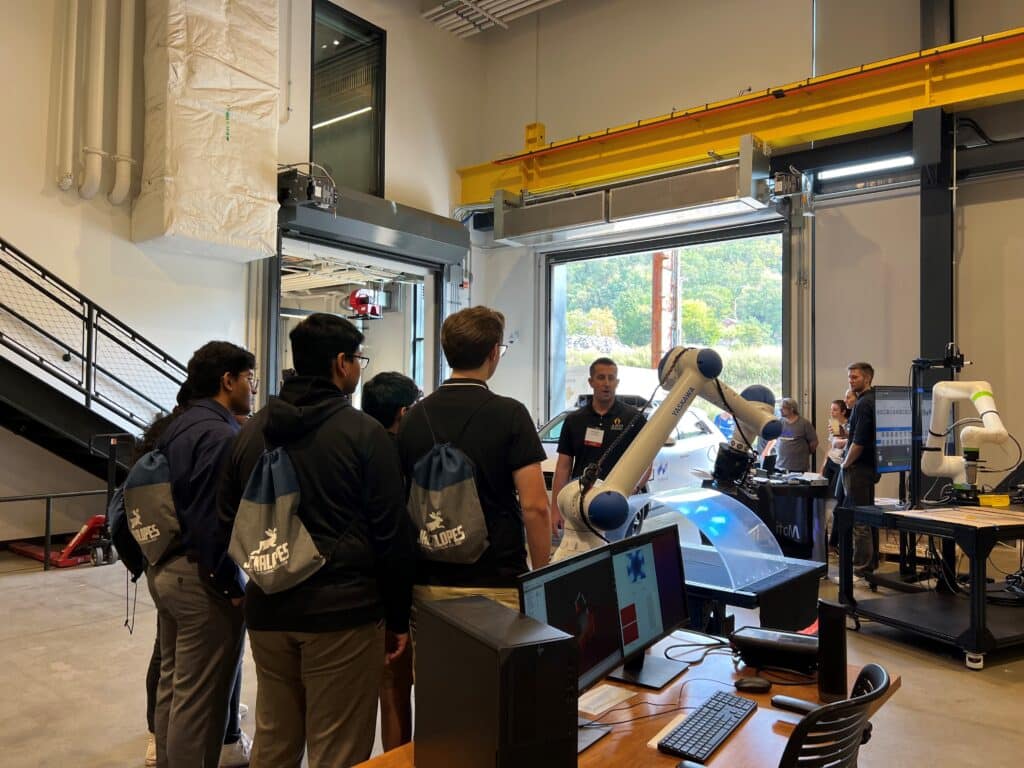

Robotics Manufacturing Hub, Regional Innovation Accelerators and Mill 19 Build-Out

As our internal team of robotics experts grew, so did our capabilities. In April, we launched our new Robotics Manufacturing Hub housed at our Pittsburgh facility. The Robotics Manufacturing Hub is funded through the Southwestern Pennsylvania New Economy Collaborative, a Regional Challenge Program. The Robotics Manufacturing Hub helps small and medium sized manufacturers in the Southwestern Pennsylvania region evaluate their operations, understand if robotics can address their challenges, and prototype robotics solutions at no cost. Upon its launch, our pipeline of interested manufacturers filled rapidly. This interest illustrates how interested manufacturers are in adopting robotics solutions; the challenge, which the Robotics Manufacturing Hub seeks to address, lies in helping them to navigate the process and risks involved.

Through the Robotics Manufacturing Hub, we built out new prototyping capabilities in our high bay, including dedicated prototyping cells for: collaborative robot (Cobot) applications, large material movement, inspection tasks, and an area for welding, grinding, and finishing tasks. ARM Members had the opportunity to explore our Robotics Manufacturing Hub during our 2023 Annual Member Meeting. We expect to have use cases and success stories to share from the Robotics Manufacturing Hub in 2024.

Also through the Southwestern Pennsylvania New Economy Collaborative, the Regional Innovation Accelerators housed at the Community College of Allegheny County, The Digital Foundry at New Kensington, IUP STEAMSHOP, and Westmoreland County Community College’s MAKERSPACE District provide regional access to equipment and training in areas outside of the city of Pittsburgh. The ARM Institute manages these Innovation Accelerators with RIDC.

New Project Funding

We catalyzed new robotics technology projects through our 23-01 Technology Project Call. Through this Project Call, we awarded nearly $1.56M in project funding from various sources, for a total contribution of approximately $3.26M across eight projects. The Project Call centered on the following topics:

- Automated Robotic Task Planning

- Multi-Robot, Multi-Human Collaboration, Task Sharing & Task Allocation

- Safe and Scalable Manufacturing of Energetics

- Artificial Intelligence (AI) in Robotics for Manufacturing

- Discovery Workshops and Market Studies

To date, the ARM Institute has funded and managed more than 150 robotics and AI technology and workforce development projects. Learn more about the eight projects funded through this Project Call here.

Growing In-House Robotics Engineering Capabilities

Strengthening our in-house robotics engineering capabilities continued to be a priority in 2023. With this growing expertise, the ARM Institute can take on projects that allow us to better direct the design and development of robotics systems. We’re leveraging this new ability in the RACER – MASCEI (Rapid-Response Automated PPE Production in Shipping Containers – Enabling Manufacturing Automation, Supply Chain Diversification and Addressing the Environmental Impact of PPE) Project.

Working with AFFOA (Prime Contractor), Henderson Sewing, Sewbo, Siemens, Carnegie Mellon University, Bluewater Defense, and Yaskawa, the ARM Institute is the Principal Investigator for this project that seeks to catalyze an automated, mobile and deployable solution that can rapidly manufacture PPE, specifically surgical masks and general use face masks, where and when PPE is needed with a minimum of resources, training, and time needed to set up and begin production. The ARM Institute team is managing the overall project, leveraging outputs from prior ARM Institute projects, and directing the design and development of the system.

Growing our internal robotics expertise has created new project management and engineering capabilities for the ARM Institute.

An Emphasis on Artificial Intelligence (AI) for Robotics in Manufacturing

Internally, we continued working on strategies to help the manufacturing industry navigate the use of AI in robotics. AI grabbed headlines previously occupied by myths about robots taking jobs in 2023. The ARM Institute’s technology strategy goes beyond the buzzwords to identify tangible opportunities and risks associated with AI in robotics for manufacturing.

We expect to have more updates about our plans in 2024 – stay tuned to our website and subscribe to our newsletter to receive our public announcements about this effort and others. Want to give input into our AI strategy and others? Explore membership here.

Education & Workforce Development Highlights

Job Matching on RoboticsCareer.org

We launched job matching on RoboticsCareer.org, our national workforce resource in 2023. Job matching enables users to find robotics jobs in manufacturing that align directly with their skills, competencies, and goals. Jobs on RoboticsCareer.org, which are updated automatically twice a week, are curated and align with our identified career pathways.

With job matching, we also introduced the ability for job and education seekers to create profiles on RoboticsCareer.org to track their career progress, save jobs and training programs, and be alerted when new opportunities match their goals. Since launching profile creation in the late summer, more than 700 job and education seekers have created accounts on the site. General usage of RoboticsCareer.org also grew; since its general launch in 2021 more than 70,000 people have used the site to search for careers and education.

ARM Endorsement

The ARM Institute Endorsement Program provided through RoboticsCareer.org recognizes the nation’s most effective training programs for robotics careers in manufacturing. With more than 16,000 programs listed on RoboticsCareer.org, ARM Endorsement is key to helping students find training programs that are proven to give them the skills that they need. Endorsed programs have passed a rigorous evaluation process completed by subject matter experts. The criteria used to evaluate both organizations and their programs based upon the following benchmarks:

- Relevance to the Industry

- Effective Curriculum

- Impact of the Program

- Program Sustainability

- Transportability

In 2023, we endorsed new training programs, bringing the total number of ARM Endorsed training programs to over 30. You can explore all Endorsed Programs here.

Future of Work Report

In collaboration with Carnegie Mellon University’s Block Center, the ARM Institute completed a major evaluation on the future of work in manufacturing and published the results in a 70+ page white paper. The Future of Work report was born out of a need to understand manufacturing workforce trends caused by disruptive technologies such as robotics, automation, and artificial intelligence in order to prepare the manufacturing workforce for the future nature of work. The report leverages existing research and the expertise of the ARM Institute and Block Center teams and of organizations—education providers, manufacturers, robotics companies, and unions— to gain insight on workforce issues and programs that are helping prepare workers for the next ten years of manufacturing.

This report is currently available only to ARM Members through the ARM Member Community. Subscribe to our newsletter to learn when the paper is publicly released or explore membership to gain access today.

Hazelwood & Greater Pittsburgh Engagement

Even as a national institute, regional engagement is key to the ARM Institute’s strategy. In 2023, we deepened our engagement with the Pittsburgh community, specifically working to provide inclusive opportunities.

We reaffirmed our support for the Hazelwood community, in which our Mill 19 facility is headquarters, through a new scholarship that we will provide to the Hazelwood-based Industrial Arts Workshop (IAW) starting January 1, 2024. This scholarship will provide funding to support a student in a year’s worth of existing IAW core programming. IAW empowers Pittsburgh-area youth and adults at the intersection of arts, community development, and workforce readiness.

Our Annual Manufacturing Day event that we host at Mill 19 with Carnegie Mellon University’s Manufacturing Futures Institute (MFI) and Catalyst Connection was our largest yet. We welcomed about 150 regional high school students, teachers, and administrators into our facility to explore careers in manufacturing through discussion pods, an exhibit hall of training providers, technology demonstrations, and tables from local manufacturers. 30 external local partners supported this year’s event. This year also featured a new session for teachers, administrators, guidance counselors, and other influencers to learn about the many resources available to help them communicate about the value of manufacturing careers.

Through funding from the Department of Labor under the Dislocated Worker Grant, the ARM Institute, Tooling-U SME, Allegheny County Department of Human Service, and New Century Careers are offering free training to fast-track individuals located in Pittsburgh into manufacturing careers. This program specifically targets individuals who qualify under the Workforce Innovation and Opportunity Act (WIOA), including dislocated workers, military spouses, workers whose plant closed, and workers who were laid off. Learn more here.

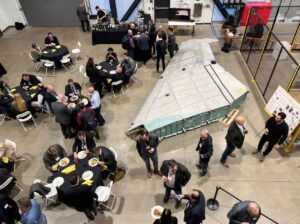

7th Annual ARM Member Meeting

In November, we convened our members in Pittsburgh for our 7th Annual Member Meeting. The ARM Institute Member Meeting is our cornerstone event and convenes representatives from across our membership for 2.5 days of networking, collaboration, and knowledge-sharing. Our 2023 event saw record participation with more than 400 attendees. The Annual Member Meeting is a key benefit of ARM Institute membership and features expert speakers, rapid-fire member introductions, a member showcase exhibit hall, project highlights, panel discussions on trends, robotics demonstrations, multiple networking receptions and activities, tours of our Mill 19 facility, and so much more.

Explore more highlights from our event here. Plus, save the date for our 2024 Annual Member Meeting taking place September 23-24 in Pittsburgh, PA!

Our Core Values

Our team also worked together to define our institute’s core values. These core values, listed below, are our deeply ingrained principles that guide our strategies, priorities, and methods of work.

Ready to Get Started?

The recap above isn’t comprehensive – it would take a mini-documentary to highlight each of our activities and success stories from the past year! Foundational to our impact and success is our member consortium. These activities don’t happen in a vacuum; our members are integral to building the future of U.S. manufacturing.

Ready to help us lead the way to a future where people and robots work together to respond to our nation’s greatest challenges and to develop and produce the world’s most desired products? Explore membership here or email [email protected] to get started.

Join our mailing list

ABOUT THE ARM INSTITUTE

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse consortium of 400+ consortium members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, with a satellite office in St. Petersburg, FL, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and X (formerly Twitter).