2024 marked yet another year of growth and impact for the ARM Institute! Check out just a few, quick highlights from 2024 in the article below.

Thank you to our 400+ member organization consortium, internal team of experts, government advisors and stakeholders, Board of Directors, and partners for enabling our impact and collaborating with us to grow U.S. manufacturing through robotics, artificial intelligence (AI), and workforce development.

$35.4M ARM Institute Continuation Agreement with the Department of Defense

While it feels like a lifetime ago, we kicked off 2024 by announcing the formal continuation of our cooperative agreement with the Department of Defense (DoD) Manufacturing Technology (ManTech) Program, which continues the ARM Institute’s funding as a national Manufacturing Innovation Institute (MII) for the next five years. The agreement’s value is an additional $35.4 million funded through 2028. The agreement also offers the Department of Defense the option to renew the contract again for another five years after 2028, bringing the Institute’s total possible primary investment to $70.4M over ten years.

The new agreement with the Department of Defense supports the ARM Institute’s operations and member services, provides funding for projects with ARM Institute members, supports existing ARM Institute capabilities, including RoboticsCareer.org, and supports new ARM Institute initiatives.

Ecosystem Highlights

Growing our Consortium with a Focus on Value

In 2024, our member organization consortium continued to grow, putting our full member count well over 450 organizations. We welcomed ARM Institute Members of all sizes, notably welcoming GE Aerospace and Magna Services of America as new Gold Members and GE Vernova joining Siemens at the Platinum level.

However, growing our member ecosystem wasn’t our only ecosystem focus this year. Our internal team, with the help of our Stakeholder Executive Committee (SEC), took a focused approach to better understanding the priorities of our member ecosystem. As we have for the past seven years, we completed our digital annual member priorities survey, however, this year we built upon this process and tasked our SEC with completing phone follow-up interviews with a variety of ARM Institute Members. These phone interviews provided a key opportunity for our Members to provide feedback directly to their SEC representatives, allowing them to potentially be even more honest than they were in our survey.

Through our survey efforts, we identified several opportunities to add value for our Members, not just from the perspective of keeping these organizations as members, but through the lens of addressing their overall business needs and priorities. The ARM Institute team spent several days together brainstorming around these topics with more action to come. ARM Members can access the findings from the digital survey and phone interviews on the ARM Member Community.

As part of our overall effort to provide even greater value, in 2025, we will roll out new member benefits that better communicate and outline the differences between our member levels. More information will be sent to our members in early calendar year Q1 2025, however, you take an advanced look at these new benefits here.

The robotics start-up ecosystem is a key piece of our consortium. The expertise, innovative ideas, and agile working environments coming out of start-ups is a key-enabler not just for the ARM Institute, but for the overall national manufacturing ecosystem. As such, we provide free membership to our robotics institute for start-up organizations that are pre-revenue with fewer than 15 employees for three years. After those three years, the ARM Institute automatically upgrades these organizations to the Steel Level. Part of our focus at the conclusion of 2024 and into early 2025 is ensuring that we follow these guidelines, which allows us to provide space for start-up organizations in their early stages while covering our consortium costs as the start-ups grow and move into revenue generation. As noted during our Annual Member Meeting, start-up organizations in our ecosystem will receive further correspondence about this process with many already having received an email about this.

Recognizing the 2024 Class of ARM Institute Champions

The ARM Champion awards recognize individuals from member organizations who have gone above and beyond to enable the ARM Institute’s mission. Champions are recognized annually at our Annual Member Meeting. This year, we added a seated dinner to our Annual Member Meeting to further celebrate the contributions of our Champions!

The 2024 class of ARM Champions included:

- Neil Ashbaugh, New Century Careers

- Gregorio Balandran, Amcor

- Xu Chen, University of Washington

- Lisa Fronczek, NIST

- Frank Henderson, Henderson Sewing

- Stuart Lawrence, Titan Robotics

- Scott Lucas, WSU Tech

- Matt Minner, Catalyst Connection

- Dijam Panigrahi, GridRaster

- John Wen, Rensselaer Polytechnic Institute

Additions to our Government Team

Our government stakeholders and advisors are a key part of our overall ecosystem. This year, we welcomed two additions to our formal Government Advisory Team: Michael Hollis has joined as the ARM Institute’s Deputy Program Manager and Aaron Sasson has joined as a Senior Program Manager supporting the ARM Institute through the PM2 Strategies team. Learn more about Michael and Aaron here.

Technology & Engineering Services Highlights

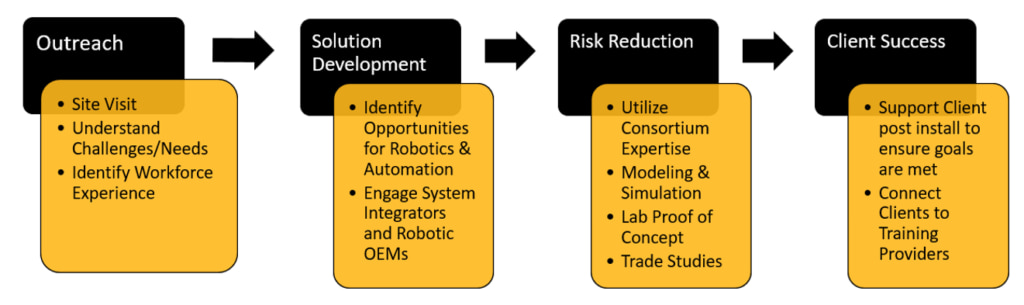

Helping Manufacturers Adopt Robotics Through Our Robotics Manufacturing Hub

Just a few years ago, the high bay at our Pittsburgh facility was mostly empty. We had a keen vision for the space, but the pandemic in 2020 set us back in terms of execution. Today, our high bay is bustling with robots of several varieties, a robust engineering staff, and projects through our Robotics Manufacturing Hub that are helping manufacturers adopt robotics.

When we announced the availability of our Robotics Manufacturing Hub, our free service that helps small and medium-sized manufacturers in the Southwestern Pennsylvania region adopt robotics, our pipeline filled instantly. This shows that manufacturers of all sizes are interested in adopting robotics, but often they don’t know where to start. That’s where free services through our Robotics Manufacturing Hub, which is funded through the New Economy Collaborative, comes in to help. We work with manufacturers to complete free automation assessments, identify where robotics and automation can enhance their competitiveness, prototype off-the-shelf or customized solutions that can address these areas, and support the manufacturer in installing the system.

We provide all of these services at no cost without requiring a commitment to installing the system. In this way, we act as a key extension of the manufacturer’s internal team with our team acting as a neutral third party that’s not looking to make a sale.

We worked with many manufacturers over the past year. Check out the video to see an example of how we helped one manufacturer go from not knowing if their desired process was even possible to a working prototype that they were able to get hands-on with at our Pittsburgh facility within weeks. This manufacturer has now officially installed the system on their floor, addressing a key problem they faced and preparing them for the future.

Ready to see how robotics can enhance your manufacturing competitiveness at no-cost? Get started here.

While our Robotics Manufacturing Hub provides free services for small and medium-sized manufacturers in the Southwestern Pennsylvania region, as limited by our grant from the EDA, we had major interest from manufacturers that fall outside of these constraints. We are now working with our first set of paying customers in the Robotics Manufacturing Hub.

If you are interested in leveraging our Robotics Manufacturing Hub services, but fall outside of our current limitations. Email us at [email protected] and we’ll explore how our team can work with you.

Knowledge-Sharing Workshops

As part of our Robotics Manufacturing Hub, in 2024, we began hosting twice annual workshops for manufacturers in collaboration with ARM Member Catalyst Connection. Through these full-day workshops, we bring in subject matter experts for focused presentations on our selected topic, provide space for robotics suppliers in an exhibit hall format, and highlight key robotics demonstrations that illustrate possibilities in the workshop’s focus area. These robotics demonstrations are provided both through our existing equipment and we invite key industry enablers to bring temporary demonstrations to our Pittsburgh facility for the workshop.

As always with our Robotics Manufacturing Hub program, the presentations at our workshop are not sales-oriented, but instead focused specifically on providing lessons learned, best practices, and ways to start with robotics and automation. We center on use cases that provide tangible next steps for interested in manufacturers.

Our post-event surveys have found that greater than 80% of workshop attendees plan to work with the Robotics Manufacturing Hub, Catalyst Connection, or a robotics supplier that they met through our workshop on adopting or further exploring a robotics solution.

Our first workshop, held in the spring of 2024, was centered on Robotic Sanding and Grinding. This workshop was held as a fully in-person event, convening around 80 attendees.

In the fall of 2024, we expanded the reach of our workshop series by hosting our Robotic Welding Workshop as a hybrid event, welcoming around 80 individuals from the Pittsburgh region in-person and others from across the country through our interactive livestream.

ARM Institute Funded Technology Projects: 24-01 Technology Project Call

ARM Institute-funded technology projects remain a cornerstone of our technology program. In 2024, we hosted a core-funded ARM Institute Technology Project Call and brought back our member-exclusive Tech Day event to help our member prepare competitive responses to our Project Call. We hosted this Tech Day as a fully in-person event and featured deep dives on our Special Topic Areas, networking and project-teaming for our members, individual meetings with our Tech Team to provide feedback on our members’ project ideas, and a hands-on activity centered on tech transition for our projects.

This Tech Project Call centered on the following Special Topic Areas: Multi-Modal Inputs for AI Robotics in Manufacturing, Rapid Re-Tasking and Robot Agility, Multi-Robot, Multi-Human Collaboration, and Virtual Commissioning of Advanced Robotic Systems.

Through the Project Call, we selected six projects for funding, awarding $2.9M in project funding, for a total contribution of approximately $6.1M across the projects.

The selected projects included:

- Automated T-Shirt Assembly System (Principal investigator: Henderson Sewing Machine Company Inc; Project Team: HanesBrands Inc, Apparel Robotics, Southwest Research Institute, Interface Technologies, and MassRobotics)

- Demonstration of Rapid TPC Welding at Scale (RTX Technology Research Center; Project Team: Carnegie Mellon University, Wason Technology LLC, Collins Aerospace)

- Fixtureless Robotic Assembly and Manufacturing Environment (FRAME) 2.0 (Principal Investigator: Lockheed Martin; Project Team: University of Southern California (USC), Carnegie Mellon University, and Yaskawa)

- Adaptive Robotic Insertion of Automotive Parts using Multi-modal Artificial Intelligence (AI) (Principal investigator: ThoughtForge AI; Project Team: Siemens and Magna International)

- Automated Finishing of Castings: Parting Line Grinding (Principal investigator: CapSen Robotics; Project Team: The Ohio State University (OSU), Southwest Research Institute (SwRI), and Yaskawa Robotics)

- Agile Robotic Path Planning for Spray Coating of Complex Geometry (Principal investigator: Northrop Grumman Corporation; Project Team: Manufacturing Automation Systems (MAS) and the Ohio State University (OSU))

You can learn more about each of the selected projects here.

Organic Industrial Base (OIB) Modernization Talent Challenge Technology Project Selections

Beyond our core-funded Technology Projects, three ARM Institute consortium member projects were selected from over 100 proposals submitted to the Office of the Secretary of Defense (OSD) Manufacturing Technology (ManTech) for the Organic Industrial Base (OIB) Modernization Challenge. In addition to Project Calls funded through our primary contract with the Department of Defense, we often receive additional funding opportunities through other channels in the DoD for the ARM Institute and often our fellow Manufacturing Innovation Institutes.

Beyond our core-funded Technology Projects, three ARM Institute consortium member projects were selected from over 100 proposals submitted to the Office of the Secretary of Defense (OSD) Manufacturing Technology (ManTech) for the Organic Industrial Base (OIB) Modernization Challenge. In addition to Project Calls funded through our primary contract with the Department of Defense, we often receive additional funding opportunities through other channels in the DoD for the ARM Institute and often our fellow Manufacturing Innovation Institutes.

The OIB Modernization Challenge is the perfect example of this, as member organizations from the Manufacturing Innovation Institutes were encouraged to submit project proposals that would address key issues identified during a DoD workshop. The challenge offered up to $2.5 million in OSD-sponsored government funding to five MII-member winners. This resulted in 104 proposal submissions from member companies. Nine projects delivered their proposals to a panel of OIB experts, industry leadership and the OSD ManTech Director, Tracy Frost, based on their projected positive impact across the 47 DoD-owned OIB sites. Three of the five selected projects were submitted by ARM Institute Members.

The ARM Institute funded projects included:

- Robotic Non-Contact 3D Inspection Replacing Hard Gaging led by ARIS Technology

- Extended Reality and AI-Assisted Paint Masking led by GridRaster

- Maskless Robotic Painting with Realtime Control led by Figure Engineering, Siemens, and Lockheed Martin

You can learn more about the projects here.

25-01 Technology Project Call

Just a few weeks ago, we issued the draft version of our 25-01 ARM Institute Technology Project Call to our members. This Project Call is currently in draft format and, as such, only available to ARM Institute Members through the ARM Member Community. Heading into 2025, we will host both a members-only webinar on January 16 exploring this Project Call and a member-exclusive, in-person Tech Day event at our Pittsburgh facility on February 6 to help our members prepare competitive responses to the Project Call.

This Project Call will be released publicly on or about February 21. Stay tuned to our mailing list to learn when our Project Call is made publicly available.

Interested in attending Tech Day, but not an ARM Institute Member? Explore membership here or email us at [email protected].

Growing Areas of Focus

While the ARM Institute is tasked with growing and strengthening U.S. manufacturing at large, there are several key industries and areas that we’ve identified as being particularly ripe for robotics and that would create dual impact for industry and the Department of Defense. We selected a few of these areas and dove even deeper into them in 2024.

Robotics for Casting & Forging

One such area was robotics for casting and forging. The casting and forging industries in the U.S. are critical to the defense supply chain, but are plagued with significant issues, including personnel safety concerns, material availability, and cost. Robotics and automation are well-suited for overcoming these challenges, however, a strategic roadmap is needed to identify needs and opportunities in order to prioritize investments and overcome these challenges.

In 2024, the ARM Institute hosted several exploratory, invite-only workshops around the area of robotics forging to begin developing this strategic roadmap. We also gained overall input in this area from our Members during our Annual Member Meeting when we hosted an interactive activity during our Tech Track that sought to validate these findings for other industries as well.

Stay tuned for further updates as this work continues. Learn more here.

Artificial Intelligence (AI) for Robotics in Manufacturing

There’s no doubt that AI garnered a vast number of media headlines this year. The ARM Institute is focused on how we can go beyond the hype to generate tangible impact for manufacturers in the area of AI for robotics in manufacturing. 2024 wasn’t the start of this focus – several years ago, we hosted several virtual Discovery Workshops on AI for robotics. We took the findings and outputs from these workshops and received additional funding to further explore and build out AI capabilities for robotics.

This effort kicked off with our members over the summer when we hosted two webinar workshops in support of AI and robotics projects that is under the working title AI Data Foundry. Through this workshop, our Members provided feedback into the key components of our program that included making data and data sets more widely available for ARM Members. We continued this momentum at our Annual Member Meeting where we received detailed and helpful feedback.

We are now in the process of utilizing the feedback that we received to shape our AI Data Foundry program plan in a way that will provide the greatest impact for our Members and the industry at-large.

Beyond the AI Data Foundry program, recognition for our leadership in the area of AI for robotics in manufacturing continued to grow. Members of our team were featured speakers at several AI-centered conferences through the year. You can read more about a few of these events here.

Robotics for Textile Goods

Robotics for sewing the and the production of textile goods has been a steady area of focus for the ARM Institute. We’ve funded multiple, high-impact projects in this area. The apparel and textile goods manufacturing sector is ripe for automation with a vast majority of these tasks still being completed manually and off-shore. For example, did you know that less than 3% of the clothing that Americans wear is manufactured in the U.S. (source)? This isn’t just a consumer issue, the production of sewn goods is a key issue of national security as we need to be able to rapidly generate key defense supplies, like tents, life preservers, and other supplies.

In fact, we worked on a project this year that leveraged robotics to automate the production of LPU-21 life preservers. The result showed order-of-magnitude improvements in labor savings and was successful in reducing the manual labor time for LPU-21 life preservers by half with greatly improved quality assurance.

This is just one example that shows what’s possible through robotics for textile goods. Plus, with the ARM Institute building on the outputs of previously funded ARM Institute robotics sewing projects, the ARM Institute and our Members have key insights into best practices and lessons learned.

In 2024, we continued to explore robotics for the production of textile goods, convening experts in this area for interactive workshops where we identified industry gaps and strategic ways that we can address these gaps and needs. Stay tuned as our work continues in this area.

Education & Workforce Development (EWD) Highlights

Of course, technology development in a vacuum won’t be enough to strengthen U.S manufacturing. It’s well-documented that the number issue manufacturers face is the seemingly ever-growing manufacturing workforce gap. Continuing retirements combined with a lack of younger manufacturing workers in the pipeline inhibits the growth of U.S. manufacturing. A robust and comprehensive education and workforce development strategy is needed to navigate these issues, empower our workers, and ensure that we have the workforce needed into the future.

The ARM Institute’s Education & Workforce Development (EWD) team tackles this issue in several ways. In 2024, we continued this momentum.

Robotics & AI Skills Definition

The definition of needed skills for robotics careers in manufacturing is critical to helping students, educators, and hiring employers alike. Students need to understand where their gaps may be while educators need to ensure that they’re meeting the needs of the industry. The ARM Institute has completed critical work in this area, having worked with our Members to define the skills and competencies needed for robotics careers in manufacturing. These definitions power everything on RoboticsCareer.org – each of the 16,700+ training programs and each of the thousands of regularly updated jobs listings on RoboticsCareer.org align directly to these frameworks.

So where does AI for robotics play a role? The ARM Institute is embarking on a major effort to define the skills and competencies needed for AI careers working with robotics in manufacturing. This effort kicked off at our Annual Member Meeting, during which we hosted an interactive skills definition activity during our Education & Workforce Development concurrent track. Incorporating feedback from industry, government, and academia, the ARM Institute then formed a working group that will continue this effort, take the inputs that we received, and form defined skills.

Potentially, this could result in new competency frameworks or we will work to incorporate the needed skills into our existing three pathways. This effort is well underway with our working group meeting virtually at a regular cadence and an invite-only, in-person workshop planned for the spring. Stay tuned for more information about this work or email us at [email protected] to learn more.

Endorsement Project Call

ARM Institute Endorsement evaluates and recognizes the nation’s most effective training programs for robotics careers in manufacturing. Following a thorough review by industry subject matter experts, training programs that become endorsed receive priority listing on RoboticsCareer.org, additional outreach resources, inclusion in SEO-driven blogs, rotating features on the homepage of RoboticsCareer.org, and access to our Endorsement Council where we share best practices.

In 2024, we released an Education & Workforce Development Project Call centered on enabling ARM Institute Members to apply to undergo the Endorsement audit at no-cost. We released this Project Call around the time of our Annual Member Meeting and are in the process of reviewing the submissions.

Supporting the Manufacturing Ecosystem through RoboticsCareer.org

The reach and impact of our national workforce resource, RoboticsCareer.org continued to grow. More than 79,700 individuals used RoboticsCareer.org in 2024, an increase of 160% from the previous year, thousands have created an account on the site, 16,700+ training programs are listed, and thousands of curated jobs are added and updated biweekly. That’s a lot of reach!

The reach and impact of our national workforce resource, RoboticsCareer.org continued to grow. More than 79,700 individuals used RoboticsCareer.org in 2024, an increase of 160% from the previous year, thousands have created an account on the site, 16,700+ training programs are listed, and thousands of curated jobs are added and updated biweekly. That’s a lot of reach!

Throughout the year, we added new functionality to the platform, including a revamped homepage, job previews that feature videos, average pay information, and other key career metrics, the ability for individuals to select a desired career pathway and track their progress, the ability for individuals to spotlight their military experience and robotics competition experience on their profiles, and more that you can read about here.

This fall, our team has been focused on a new release that will make new resources available to help hiring manufacturers and employers find and contact qualified workers. Stay tuned for more information about this year, however, you can expect these features to center on skills identification with an emphasis on applied skills, robust search capabilities in our talent database, and more.

On the job seeker side, we’ll be releasing new ways for individuals to see how their account looks to hiring manufacturers, employers, and recruiters, as well as new ways to enhance their profiles.

Stay tuned for more information about this release and a forthcoming webinar that will walk you through how you can use the new capabilities. Create an account to get started today or email us at [email protected].

Future of Work Research Report

While we released our Future of Work research report to ARM Members at our 2023 Annual Member Meeting, we issued the 70-page report publicly this past spring. This robust research report details how advanced technologies, chiefly robotics, automation, and AI, are changing the nature of manufacturing careers and the actions needed to prepare the U.S. manufacturing workforce for these changes.

You can download the report and learn more here.

In 2025, we’ll be building upon the learnings from this report with additional insights that dive deeper into key focus areas and topics that resulted from our report. Stay tuned to our mailing list to learn when these are available.

8th Annual Member Meeting

We welcomed more than 350 subject matter experts across industry, government, and academia to our 8th Annual Member Meeting, which took place September 23-25 in Pittsburgh, PA! Our event featured ample networking time, our ever-popular Member Five Minute Pitches, robotics demonstrations from our Robotics Manufacturing Hub during our indoor/outdoor networking reception at our Pittsburgh headquarters, presentations by industry experts, including Dr. Charles Ormsby (Division Chief for Air Force Research Lab (AFRL) Manufacturing, Industrial Technologies, and Energy Division), Alex Shikany (Vice President, Membership & Market Intelligence at ARM Member A3), Dr. Paul D. Nielsen (Director and Chief Executive Officer of Carnegie Mellon University’s Software Engineering Institute (SEI)), Dr. Brad Conrad (Education and Workforce Development Manager within the Partnerships and Outreach Division at the NIST Office of Advanced Manufacturing), and others.

As always, the ARM Institute thanks our Platinum Members and Member Meeting sponsors for supporting this important event and, by doing so, helping to strengthen U.S. manufacturing: GE Vernova, Siemens, AMT – the Association for Manufacturing Technology, CarnegieBosch Institute, Corsha, Fivestar, GridRaster, Mason & Hanger, NC3 – National Coalition of Certification Centers, Titan Robotics, Universal Robots, and Yaskawa.

Dive deeper into our Annual Member Meeting here.

Save the date! Our 2025 National Member Meeting will take place Sept. 3-5 in Pittsburgh, PA. This event is open only to ARM Institute Members. Registration information will be sent in the early spring.

Further Engagement & Visits

Visits by Leaders

Leaders from across the country are taking note of our impact. Again in 2024, we hosted many visitors throughout the year. While it would be an impossible task to name each visit and person, below are just a few highlights:

- Lael Brainard, Biden’s top economic adviser, visited the ARM Institute and toured our Robotics Manufacturing Hub as part engagements with programs and organizations that received funding from the Regional Challenge grants. We were joined by our fellow awardees from the New Economy Collaborative

- In January 2024, Ira Moskowitz (ARM Institute CEO) provided remarks and personally introduced Pennsylvania Governor Josh Shapiro when he unveiled the new Pennsylvania economic development strategy at our Pittsburgh headquarters.

- We also hosted representatives from the Department of Defense’s Office of Strategic Capital (OSC), including Vyshi Suntharalingam (Chief Technology and Engineering Officer), at our Pittsburgh headquarters. Following the visit, OSC opted to attend our Annual Member Meeting where they hosted a table in the Member Showcase Hall and an interactive roundtable break-out discussion.

- As part of their visit to Pittsburgh, we hosted a tour and visit from a delegation of leaders from the U.S. Navy, including Rear Admiral Thomas Anderson.

- ARM Member AMT – the Association for Manufacturing Technology hosted their 2024 Joint Technology Summit at our Pittsburgh headquarters. This event brought together the technology committees of AMT – The Association For Manufacturing Technology, AGMA (American Gear Manufacturers Association), and NTMA (National Tooling and Machining Association) to explore the latest in manufacturing innovation and advancements ranging from precision gears for robotics to the integration of AI in digital manufacturing.

Events, Engagements, Tradeshows, and More

As always, we maintained a robust event schedule. Through a variety of ARM Institute hosted events, spanning our Annual Member Meeting, Tech Days, Workshops, our Manufacturing Day, and others, we welcomed around 1,000 individuals to in-person events. On the virtual event side alone, nearly 600 individuals joined us across our public webinar series and member-only Tech Talks, Workforce Talks, Member Webinars, and New Member Exchanges.

We also connected with subject matter experts at nearly 100 external tradeshows and events, which included IMTS, Automate, the AI Manufacturing & SCADA Conference, the Robotics Summit, the Vex Robotics World Championships, the Defense Manufacturing Conference, the AI Horizons Conference, the Pittsburgh Robotics Network’s Discovery Day event, and countless others. Want us to present at a conference or event that you’re hosting? Let us know at [email protected].

ARM Institute in the News

It would be impossible to list each and every news article, of which there are well over a hundred, that featured the ARM Institute and our work, but below are a few of our favorites from the year:

- Ira Moskowitz (ARM Institute CEO) broke down the details of the ARM Institute’s impact with Automation World

- Ira Moskowitz broke down how AI can strengthen US manufacturing with CMU

- How robots are transforming an old school PA manufacturing firm – and reducing risk of injury

- Suzy Teele, ARM Institute Chief Strategy Officer, explored how we help manufacturers adopt robotics at the IMTS Creators Lounge

- RoboticsCareer.org’s New Functionality Helps to Address Workforce Gap

- Livia Rice, ARM Institute Director of Outreach & Engagement, caught up with ARM Member SME about the impact of AI and robotics on manufacturing

Want to interview an ARM Institute expert? Let us know by emailing us at [email protected].

Awards

We were once again a finalist and a winner for several awards!

-

Defense Manufacturing Technology Achievement Awards: Two ARM Institute technology project teams led by Michael Skocik (ARM Institute Director of Federal Technology Initiatives) won Defense Manufacturing Technology Achievement Awards. These awards are given to teams comprising government, industry and academia employees responsible for outstanding projects in manufacturing technology. The awarded projects were: (1) Spatial Intelligence with Dynamic Extended Reality (SPIDER) for Manufacturing and Sustainment with GridRaster and (2) Depot Factory AI Robotics (DFAIR) with Titan Robotics.

- Pittsburgh Technology Council Tech50 Awards: We were a finalist in the Company Culture category and won the Tech50 award for Manufacturing Excellence

- Pittsburgh Business Times Best Places to Work: We were a finalist again for the Pittsburgh Business Times Best Place to Work award.

Join Us on Our Mission

If anything that we’ve mentioned in this post sounds interesting or if you’re ready to get work strengthening U.S. manufacturing through robotics, AI, and workforce development, the best way to engage with us is through ARM Institute membership. Learn more about membership here or email us at [email protected] to see how we can collaborate with you.

Our 400+ member organizations collaborate with us to lead the way to a future where people and robots work together to respond to our nation’s greatest challenges and to develop and produce the world’s most desired products. Whether you’re a large or small manufacturer, a robotics or AI supplier, community college, large research university, economic development organization, or somewhere in between, there’s a place for you in the ARM Institute’s member ecosystem.

Explore membership

ABOUT THE ARM INSTITUTE

The Advanced Robotics for Manufacturing (ARM) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse ecosystem of 400+ consortium members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, with a satellite office in St. Petersburg, FL, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and X (formerly Twitter).