The ARM funded technology project “Passive Object Tracking” has demonstrated successful outcomes, including a significant return on investment upon deployment. Siemens has continued the development and utilization of the technology modules with its own manufacturing process and ITAMCO has planned the technology transition into their facility.

Participants

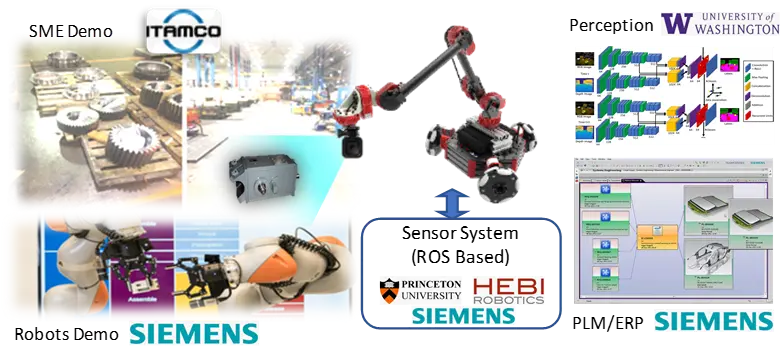

Siemens Corporation, Corporate Technology (PI), Indiana Technology and Manufacturing Company (ITAMCO), HEBI Robotics, Princeton University, and University of Washington

Approach

This project team aimed to create an automated tracking and traceability solution for part accountability in manufacturing processes by leveraging the latest sensing, perception, and mobile robot technologies.

Most tracking solutions today exist in the logistics domain. In product inventory and distribution, companies typically determine current and past locations through a series of barcode or RFID scans unique to each item. This project aims to eliminate the need for unique identifiers and rather utilize the advanced sensing and perception capabilities of robotics to track items throughout the manufacturing process and tie that information back into the company’s Enterprise Resource Planning (ERP) software.

The team took a step-by-step approach to developing this technology, first in simulation, then in a laboratory setting, and finally demonstrating the system on the ITAMCO factory floor.

Results

The team developed a novel system and method for component track and traceability via sensor fusion and digital twin technologies, resulting in several new patents. The final demonstration showcased the system’s CAD-based perception algorithm on semantic segmentation, accurate robot perception of its own location, and the location of the parts identified and tracked, repeatable robot navigation, global/ local path planning, and obstacle avoiding, and tracking of part location as they move based on perception and logic. The system is composed of several technology nodes which will be useful to the team and ARM Members as a system and individually: object detection using alternative spectral sensing, object detection with localization and recalibration, CAD-based object detection pipeline, robot perception and control, and the tailored sensor package design.

The industrial partner, ITAMCO, estimated significant return on investment for this technology with a payback period of only 6 months and a 5-year ROI of more than $300K for one deployed robot.

Next Steps

Both ITAMCO and Siemens are working on further development to fully mature and utilize technology modules from this project in their businesses. This project demonstrated impressive technological gains and will result in meaningful impact to these companies.

ARM Institute Annual Member Meeting

Join us October 13-15, 2020 for our Annual Member Meeting! Registration is free and open to ARM Members only. The Annual ARM Member Meeting is our cornerstone event and brings together representatives from across 260 member organizations for three days of high-energy engagement and information sharing. Spanning industry, government, and academia, our event highlights important solutions in robotics and workforce development to strengthen U.S. manufacturing for the defense and commercial industrial bases. Email [email protected] for more information.