Project Highlight: RoboRecharge

Project Team & Funding

Project Team Members: Southwest BotsIQ (an ARM Endorsed training program) and the ARM Institute.

RoboRecharge is the result of collaboration between the ARM Institute and Nextflex, one of the ARM Institute’s fellow Manufacturing Innovation Institute part of the Manufacturing USA Network. RoboRecharge leverages Nextflex’s FlexFactor program.

Background & Problem Statement

The manufacturing industry is facing a historic workforce crisis. Current workers are retiring at a rapid pace, and the industry lacks the talent needed to replace these experienced workers. Studies estimate that these retirements combined with a historic skills gap will leave 2.4 million manufacturing jobs unfilled in the coming years.

The manufacturing industry needs to attract younger workers, however, misconceptions about working in manufacturing have left parents, students, and teachers leery about manufacturing careers. Parents and teachers often see manufacturing jobs as being unstable, low-paying, and filled with dull, dirty, and dangerous tasks. Students typically perceive manufacturing work as uninteresting and unimportant.

The reality is that manufacturing jobs today are safer, more engaging, and higher paying than those of the past. For example, an entry-level robotics job in manufacturing, such as a Robotics Technician role, pays $61,000 on average. Manufacturing is also critically important to our national resiliency; the manufacturing workforce powers everyday life in the U.S.

RoboRecharge works to combat misconceptions by exposing students, parents, and teachers to robotics opportunities in manufacturing and teaching hands-on skills. Through visits to local manufacturers and robotics training providers, and exposure to local subject matter experts, RoboRecharge shows students, parents, and teachers the new reality of working in manufacturing.

Approach

Managed by Southwest Bots IQ and leveraging the FlexFactor format, RoboRecharge is delivered directly through classroom instruction in Southwestern Pennsylvania and was originally designed for students in middle and high school. In the past year, RoboRecharge has modified the program with younger students in mind – currently the program can serve children of all ages – even those in kindergarten!

The program’s foundation is based on three primary pillars: (1) engagement with robotics technologies, (2) familiarization with the principals of entrepreneurship, and (3) exposure to the training and career pathways that lead into the advanced manufacturing sector.

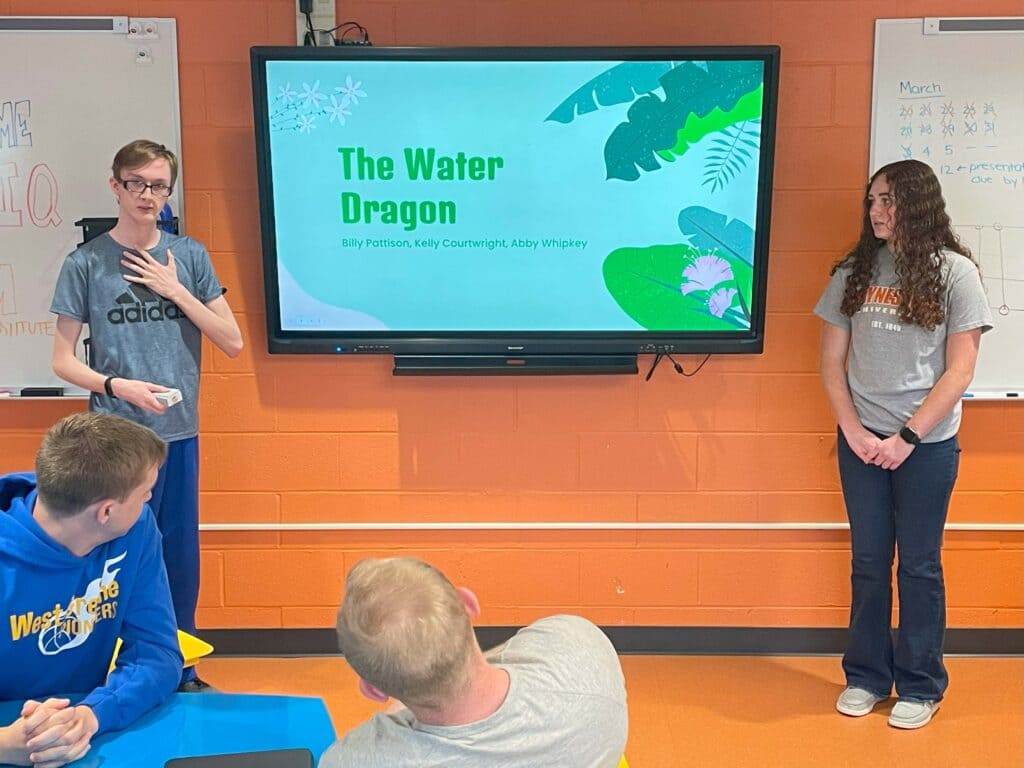

Students form teams and develop a pitch for a robotics product through four phases:

- Problem Identification: Students identify a real-world problem that, if solved, would benefit humanity.

- Product Development: Students come up with a concept for a robotics and manufacturing-based product to solve the identified problem.

- Business Model Development: Students create a business model to manufacture, market, and sell the product.

- Final Pitch: Students create and rehearse a 3–4-minute pitch, which is later presented to a panel of industry professionals arranged by Southwest BotsIQ.

RoboRecharge also includes an Industry Day, during which students tour a local manufacturing facility, and a College Day, during which students tour a local training provider.

The program does not require teachers to have prior robotics knowledge or training, lowering the barriers for instructors to teach robotics skills. In a world where teachers are asked to do more with fewer resources, RoboRecharge provides a solution in-a-box for teaching robotics skills and exposing students and parents to opportunities in manufacturing.

Impact

Since its launch in 2019, nearly 200 students in the Southwestern Pennsylvania region have participated in RoboRecharge.

“My students loved the RoboRecharge Challenge. It was great to see my students think about how they can solve real world problems in unique ways. I also loved that students were challenged to think about the whole problem from concept, to fabrication to marketing. We look forward to completing RoboRecharge next year to see what fun and exciting new ideas we can come up with!”

- Sara Perkins, West Greene High School

“With RoboRecharge, students have the freedom to explore industries that interest them, and that’s how we connect kids to careers. We create the platform, empower teachers, and then let the next generation choose a path to go down. Kids should be empowered to pursue their professional interests, and robotics is a great field to support this!”

- JoAnna Dehler, BotsIQ STEM Program Coordinator

Learn More

To learn more about RoboRecharge or get involved, contact Southwest BotsIQ at or email [email protected].

Southwest BotsIQ is an ARM Endorsed training program, which means that the program has passed the ARM Institute’s rigorous evaluation process and is proven to give students the skills they need for robotics careers in manufacturing. Learn more about Endorsement here.

Plus, learn more about robotics career pathways in manufacturing, the skills needed for these careers, and get personally matched to robotics training programs and jobs in manufacturing on the ARM Institute’s national workforce resource: RoboticsCareer.org.

Join our mailing list

About the ARM Institute

The ARM (Advanced Robotics for Manufacturing) Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA® network. The ARM Institute leverages a unique, robust, and diverse ecosystem of 390+ consortium members and partners across industry, academia, and government to make robotics, autonomy, and artificial intelligence more accessible to U.S. manufacturers large and small, train and empower the manufacturing workforce, strengthen our economy and global competitiveness, and elevate national security and resilience. Based in Pittsburgh, PA since 2017, with a satellite office in St. Petersburg, FL, the ARM Institute is leading the way to a future where people & robots work together to respond to our nation’s greatest challenges and to produce the world’s most desired products. For more information, visit www.arminstitute.org and follow the ARM Institute on LinkedIn and Twitter.