Background

Apparel manufacturing has seen very little innovation over the past decade, as the costs to move production overseas are often lower than the cost to invest in developing needed automation. There are also currently no commercially available robotic solutions that can reliably grasp a single layer of fabric from a bundle. This project focuses on the development of a robotic system that can accurately pick and place select fabric types that represent a substantial share of the apparel market, focusing specifically on men’s trousers. This innovation has the potential to greatly strengthen and possibly re-shore apparel manufacturing, from the manufacturing of military uniforms and fire retardant clothing to more commercial wear.

Objective

Create a cost-effective robotic solution to apparel manufacturing to re-shore apparel production.

Technical Approach

The expected project outputs include:

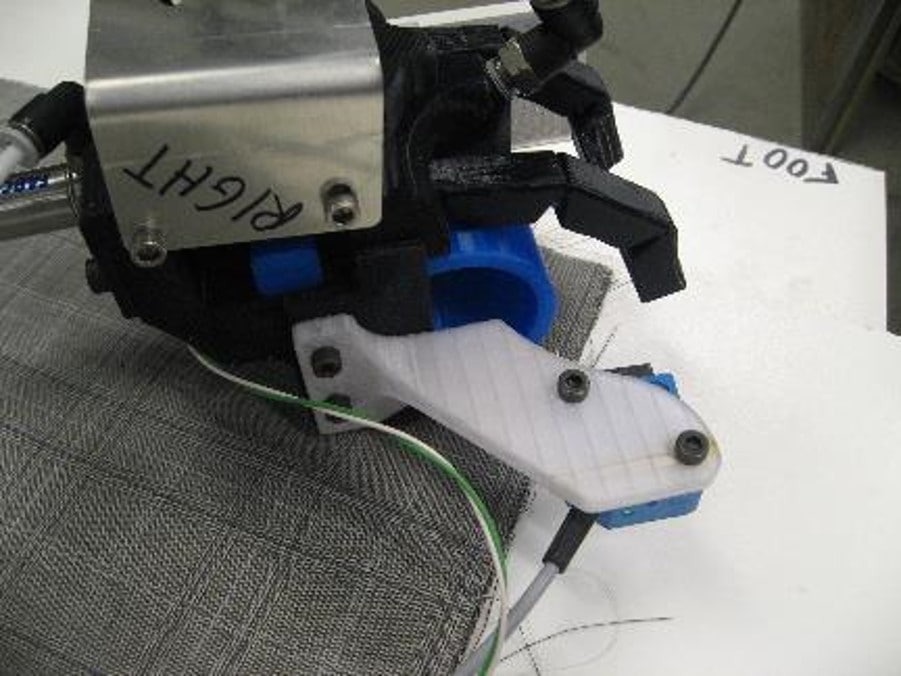

- Development of a Robotic Sewing WorkGroup with an end-effector that can load single ply work pieces from a bundle into multiple serge sewing systems reliably and repeatedly

- Open source software that will enable set-up, operation, and support of the robotic system

Participants

Rensselaer Polytechnic Institute (Principal Investigator), Interface Technologies, DAP America, Hickey Freeman, National Safety Apparel, Yaskawa America