Aircraft Coating Application Background

In February 2020, the Advanced Robotics for Manufacturing (ARM) Institute hosted and participated in the Joint Summit: Robotics in Sustainment II (JROBOT) event. The four-day summit brought together experts across government and the armed services to develop and recommend Office of the Secretary of Defense (OSD) policies for coordinating and expanding the use of industrial robotics in sustainment activities across all military branches.

Prior to the event, ARM consortium members were invited to submit projects for funding in support of the DoD’s sustainment goals through the ARM 19-04 Technology Project Call, which opened in late 2019. From there, a competitive group of project teams were invited to present their project proposals in-person at the Joint Summit.

The selected robotics projects help to meet the Department of Defense sustainment needs, which focus on the maintenance and repair of military assets over their lifetime. Spurring robotics technology and workforce solutions is critical to maintaining military equipment, lowering the cost of repairing assets, and training the staff needed to complete this important work.

Aircraft Coating Technical Approach

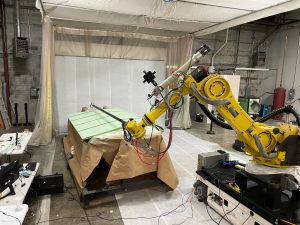

Current aircraft coating applications are purpose-built for very specific tasks, costly, and require a high-level of expertise in automation systems. This project proposes a mobile coating solution that will minimize the cost to implement, reduce the time spent, prioritize human safety, and can be used more generally. This will be completed through the development of a robotic end effector that can service multiple coating applications, automated coating application parameters, a mobile system to robotically apply coatings, inspection parameters for quality inspection, and robotic path planning software.

Aircraft Coating Application Impact

The automation of painting and the application of advanced coatings is high priority for the DoD. The Mobile Autonomous Coating Application System for Sustainment project directly addresses some of the key robotic capabilities that resolve several of the critical needs towards achieving autonomous mobile multi-agent robotic spray systems that are capable of painting large, complex and eventually complete aircraft.

The ARM Institute, in collaboration with the project team, was able to demonstrate the program’s results to more than 75 individuals representing over 20 organizations during the final hybrid out-brief and live demonstration. A broad Department of Defense (DoD) participation included: AFRL ManTech, WR-ALC, OO-ACL (F-22), Hill AFB, Naval Undersea Warfare Center, ONR, USMC Logistics Command. Industry representatives included LMCO Corporate Technology, Skunkworks, F-22, F-35; ABX, SwRI, Spirit AeroSystems, Wichita State, and more.

Aircraft Coating Application Next Steps

The project outputs have considerable impact for the ARM Institute, the institute’s membership, and the Department of Defense. The ARM Institute, in partnership with the DoD, is pursuing continued development efforts for this project.

A key benefit of ARM Institute funded projects is the ability to improve the state of the practice, while identifying challenges that have the potential for considerable improvements. The following recommendations were presented by the project team for possible future development programs:

- Paint “stitching” to prevent checkerboard appearance,

- Avoid hard cure lines during repositioning/scanning activities,

- C1D1 hardware requirements/design considerations

- Tool path generation across complex (contoured) geometries and/or confined spaces,

- Safety systems necessary to allow operators in same booth/work area as robotic system,

- Multi-robot/system integration or collision prevention integration,

- Refined and improved user interface for operators,

- Simultaneous platform movement with spray operations,

- Initial surface detection is critical to overall system performance, alternate methods/data may be possible to supplement sensor detection.

The ARM Institute’s Role

“Engaging with the ARM Institute provided the team an opportunity to develop and demonstrate an innovative robotic capability that can be expanded to meet the needs of our Department of Defense (DoD) customers. The ARM Institute facilitated a partnership with our DoD Sustainment Technical Advisors and helped guide a prototype solution that advances the DoD mission for robotics in sustainment. This effort demonstrated a disruptive capability and significant opportunity for the sustainment community in the future.” – Lockheed Martin