Background of this Robotic Clothing Manufacturing Project

Despite being universally adopted throughout traditional manufacturing, industrial robots have failed to find a place in garment sewing applications due to the robots’ difficulties in handling limp textiles. This makes the global apparel industry strongly dependent on, manual labor. The outputs from the ARM Institute-funded robotics project “Robotic Assembly of Garments” created considerable impact by taking the first steps in revolutionizing this trillion-dollar industry via a new robotic assembly process that stiffens garment pieces by laminating its fabric with water-soluble thermoplastic polymer, helping to bypass some limitations that were blocking the widespread implementation of robotic garment assembly in the U.S. manufacturing ecosystem.

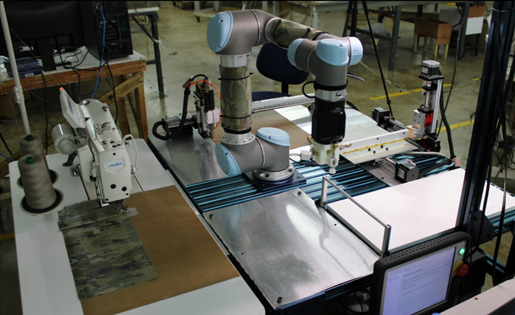

This flexible robotic system was developed to handle and assemble fabric pieces into garments. Traditional sewing machines were controlled via Robot Operating System (ROS) to achieve synchronized operation with the robot. The polymer utilized in the process can be easily removed through washing and can be recycled for multiple process cycles. The technology was successfully demonstrated at Bluewater Defense production facility and is being further matured for more complex sewing operations in ARM-TEC-20-01-F-15 (usecase: medical gowns), ARM-TEC-20-02-F-03 (usecase: face mask).

Objective of of Robotic Clothing Manufacturing Project

Advance robotic technology for automated garment sewing in order to re-shore apparel manufacturing.

Technical Approach to this Robotic Clothing Manufacturing Project

The key to this project is its modular nature, where each individual building block can be replaced by different building blocks that are more suitable for different use cases.

Project outputs are expected to include consortium developed intellectual property (CDIP) focused on the following:

- Simulation-based robot planning module for thin sheets that need to be assembled and have a wide range of variability

- Shape identification and pose estimation of 2D/3D sheets

- Modular ROS-architecture for overall functionality

- Adjustments to visual servoing library ViSP for handling flexible sheets and multiple cameras

- ROS packages for recognition, pose estimation, and grasping of thin sheets

Impact of this Robotic Clothing Manufacturing Project

The team developed a novel system and method for using robotic systems to accomplish sewing operations including folding, joining, and stitching fabrics. In the demonstration, this system was successfully able to sew the pocket flaps for military uniform pants. The project served as a critical first step in proving the viability of this technology surrounding robotic garment assembly. The system is capable of producing parts that satisfy the Bluewater Defense quality requirements. While the robotic system currently has a higher cycle time than human operators, it has the potential to lead to greater automation and shorter cycles with further development.

Next Steps in this Robotic Clothing Manufacturing Project

Siemens, Bluewater Defense, and Sewbo are working on further development to fully mature and optimize this technology. Several ongoing ARM projects build upon the IP generated in this project, extending its applicability to PPE production in response to the COVID-19 pandemic and more advanced garment assembly. This project demonstrated impressive technological gains and will result in meaningful impact to the project partners and the entire ARM community.

Participants in this Robotic Clothing Manufacturing Project

Siemens (Principal Investigator), Bluewater Defense, Sewbo, University of California Berkeley